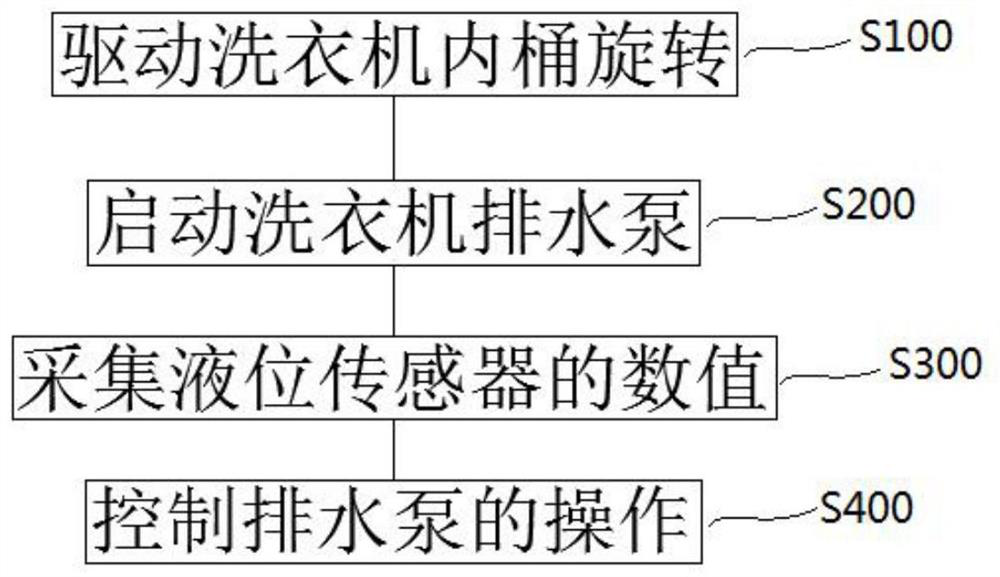

washing machine dehydration method

A washing machine and drainage pump technology, applied in the field of washing machines, can solve problems such as water leakage, water and foam cannot be thrown off normally, washing tub cannot normally enter water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

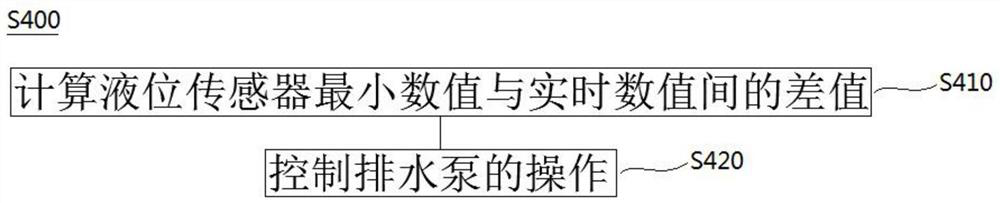

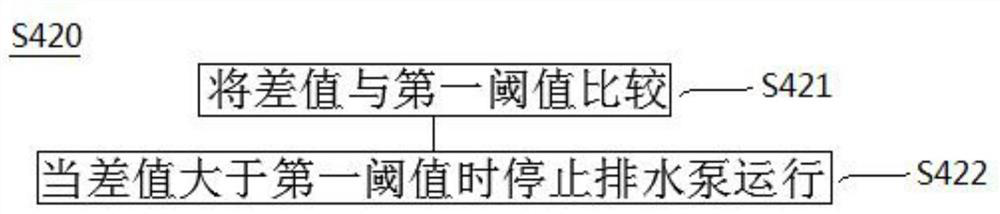

Method used

Image

Examples

Embodiment Construction

[0028]Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

[0029] During the dehydration and drainage process of the upper drainage washing machine in the prior art, in order to suppress the large amount of foam growth in the washing tub, the drainage pump usually needs to be kept in a normally open state. Since the foam trapped in the washing bucket cannot be effectively discharged through the drain pump, when the washing water in the washing bucket is sucked clean for the first time when the washing machine is dehydrated and drained, the liquid thrown out per unit time is far less than the actual discharge capacity of the drain pump , causing the drainage pump to be in a low-efficiency drainage state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com