Folded cloth treatment equipment

A technology for processing equipment and fabrics, which is applied in thin material processing, textile and paper making, fabric surface trimming, etc. It can solve the problems of staff burns and waste of staff time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

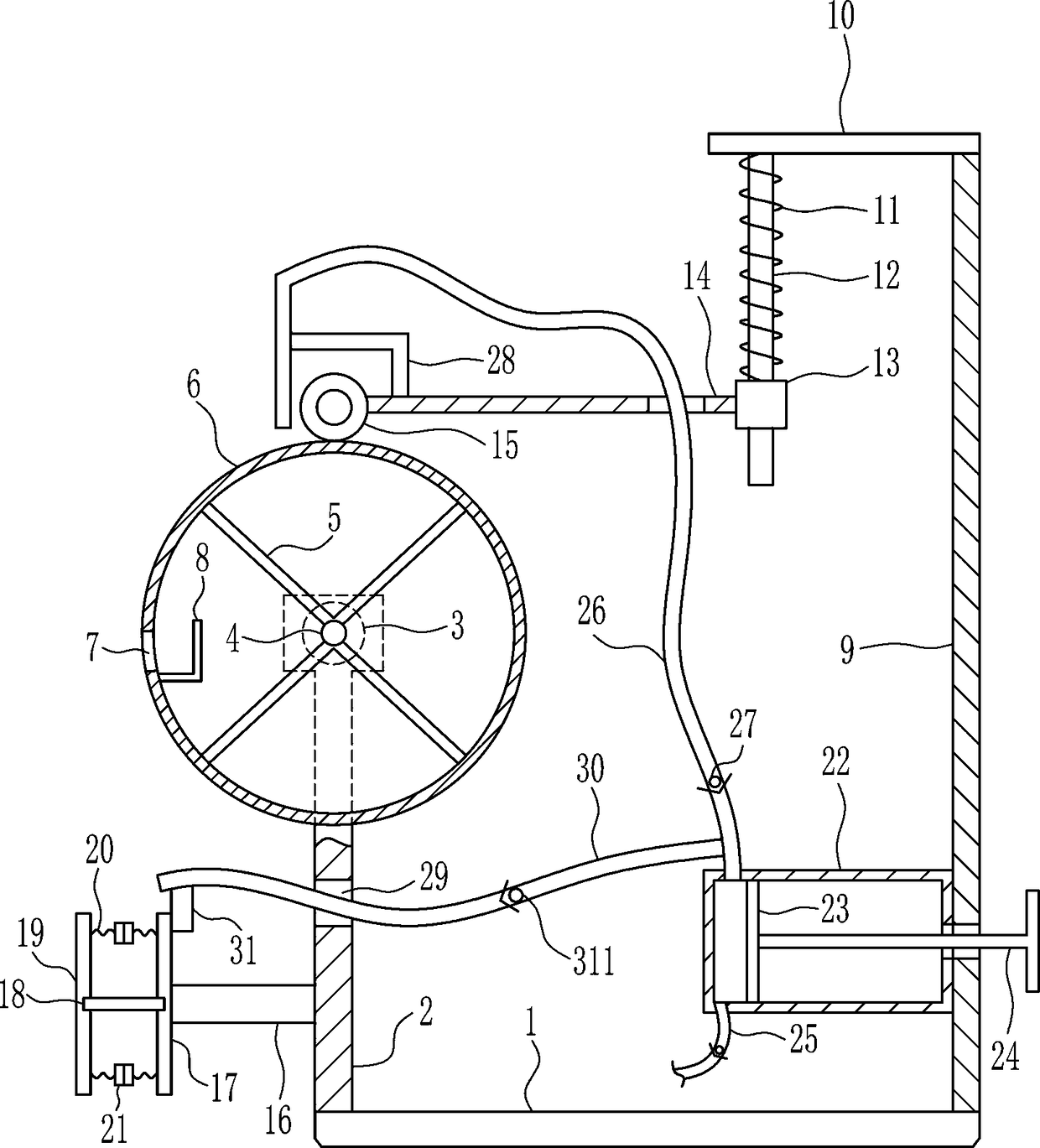

[0025] A wrinkled cloth processing apparatus such as Figure 1-5As shown, it includes a base 1, a mounting column 2, a servo motor 3, a first rotating rod 4, a rotating rod 5, a winding cylinder 6, a fixed rod 8, a right frame, a mounting plate 10, a first spring 11, a guide rail 12, Sliding sleeve 13, elevating rod 14 and cylinder 15, base 1 top left side is provided with installation column 2, and servo motor 3 is installed on the top of installation column 2, and the output shaft of servo motor 3 is provided with first rotating rod 4, and the first rotation The front end of the rod 4 is evenly provided with a plurality of rotating rods 5, the rotating rod 5 is positioned at the front side of the servo motor 3, the outer end of the rotating rod 5 is provided with a winding tube 6, and a through hole 7 is provided on the left side of the winding tube 6, and the winding tube 6. A fixed rod 8 is arranged in the middle of the inner wall on the left side. The fixed rod 8 is locat...

Embodiment 2

[0027] A wrinkled cloth processing equipment such as Figure 1-5 As shown, it includes a base 1, a mounting column 2, a servo motor 3, a first rotating rod 4, a rotating rod 5, a winding cylinder 6, a fixed rod 8, a right frame, a mounting plate 10, a first spring 11, a guide rail 12, Sliding sleeve 13, elevating rod 14 and cylinder 15, base 1 top left side is provided with installation column 2, and servo motor 3 is installed on the top of installation column 2, and the output shaft of servo motor 3 is provided with first rotating rod 4, and the first rotation The front end of the rod 4 is evenly provided with a plurality of rotating rods 5, the rotating rod 5 is positioned at the front side of the servo motor 3, the outer end of the rotating rod 5 is provided with a winding tube 6, and a through hole 7 is provided on the left side of the winding tube 6, and the winding tube 6. A fixed rod 8 is arranged in the middle of the inner wall on the left side. The fixed rod 8 is loca...

Embodiment 3

[0030] A wrinkled cloth processing equipment such as Figure 1-5 As shown, it includes a base 1, a mounting column 2, a servo motor 3, a first rotating rod 4, a rotating rod 5, a winding cylinder 6, a fixed rod 8, a right frame, a mounting plate 10, a first spring 11, a guide rail 12, Sliding sleeve 13, elevating rod 14 and cylinder 15, base 1 top left side is provided with installation column 2, and servo motor 3 is installed on the top of installation column 2, and the output shaft of servo motor 3 is provided with first rotating rod 4, and the first rotation The front end of the rod 4 is evenly provided with a plurality of rotating rods 5, the rotating rod 5 is positioned at the front side of the servo motor 3, the outer end of the rotating rod 5 is provided with a winding tube 6, and a through hole 7 is provided on the left side of the winding tube 6, and the winding tube 6. A fixed rod 8 is arranged in the middle of the inner wall on the left side. The fixed rod 8 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com