Treatment method for performing metal electroplating on oxidation film to form similar glaze light surface as well as structure thereof

A metal electroplating and treatment method technology, applied in the direction of anodic oxidation, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of reduction and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

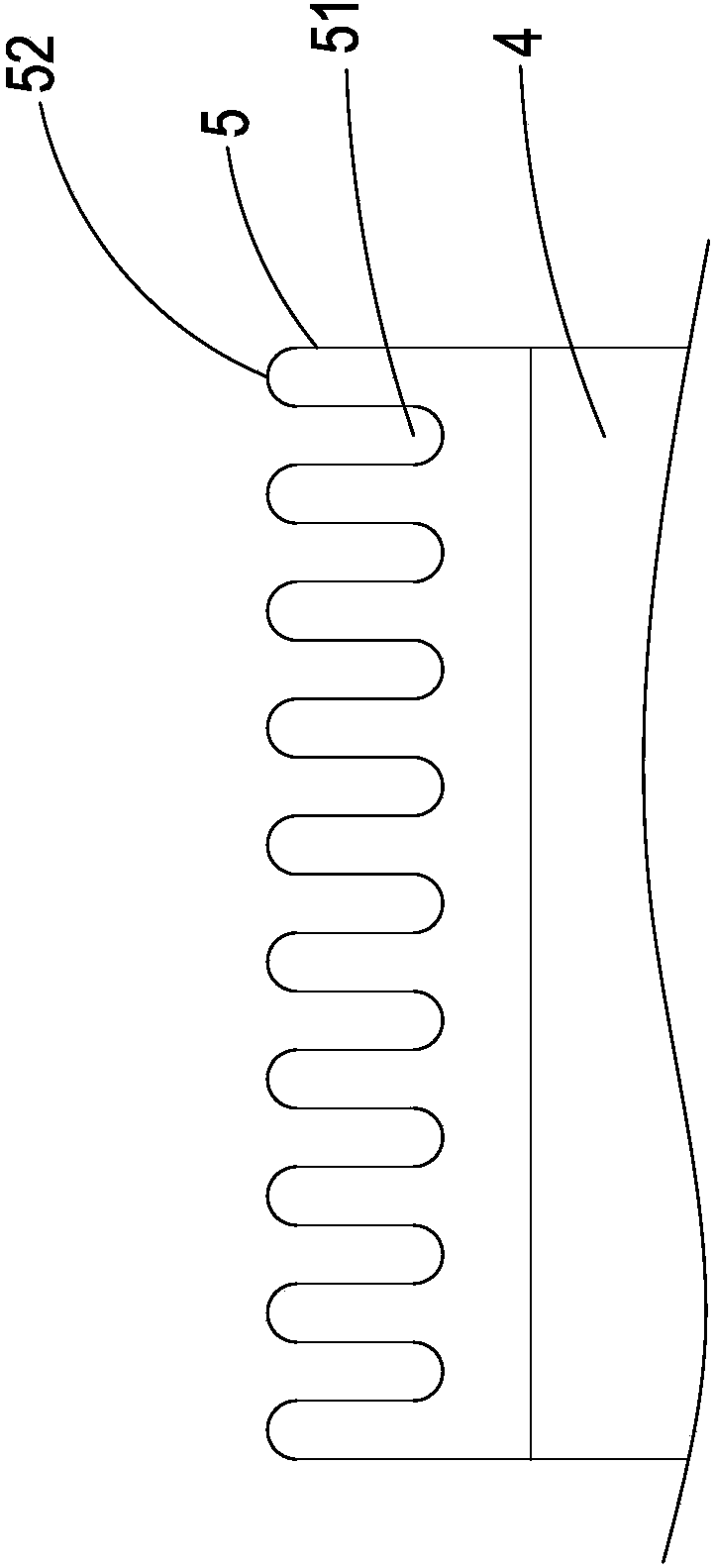

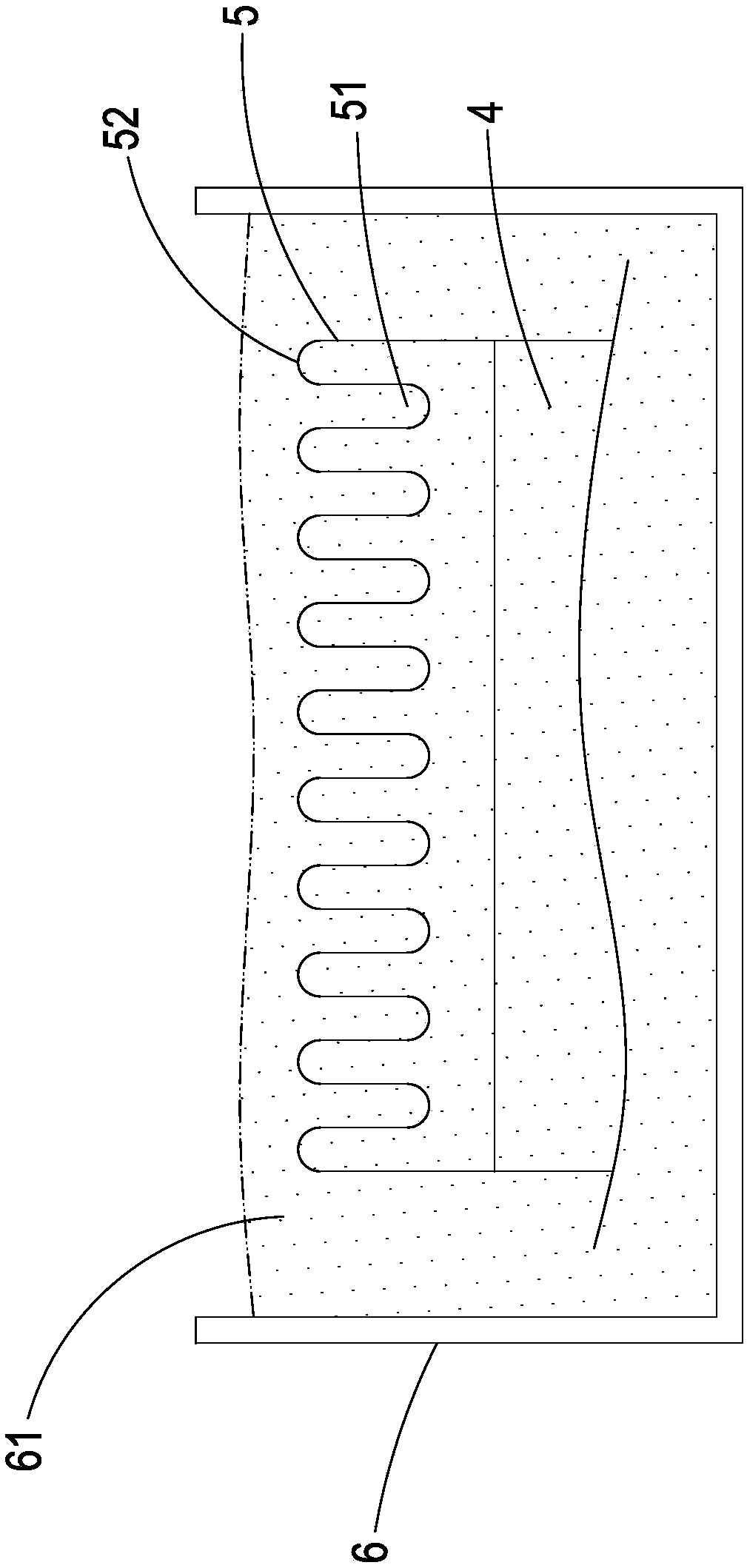

[0040] Other technical contents, features and functions of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the accompanying drawings.

[0041] see figure 1 , a schematic flow chart of forming a glaze-like surface treatment for metal electroplating oxide film. It can be seen from the figure that the steps are:

[0042] A metal substrate is provided, first waxing and polishing the metal substrate to form a mirror surface, and then removing the wax 201 remaining on the surface of the metal substrate.

[0043]Then, the metal substrate is subjected to anodic oxidation plating treatment to form an anodized film on the surface of the metal substrate, wherein the height of the anodized film is about less than or equal to 30 μm, and the surface of the anodized film has a plurality of honeycombs hole 202.

[0044] Afterwards, put the metal substrate on which the anodized film has been formed and soak in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com