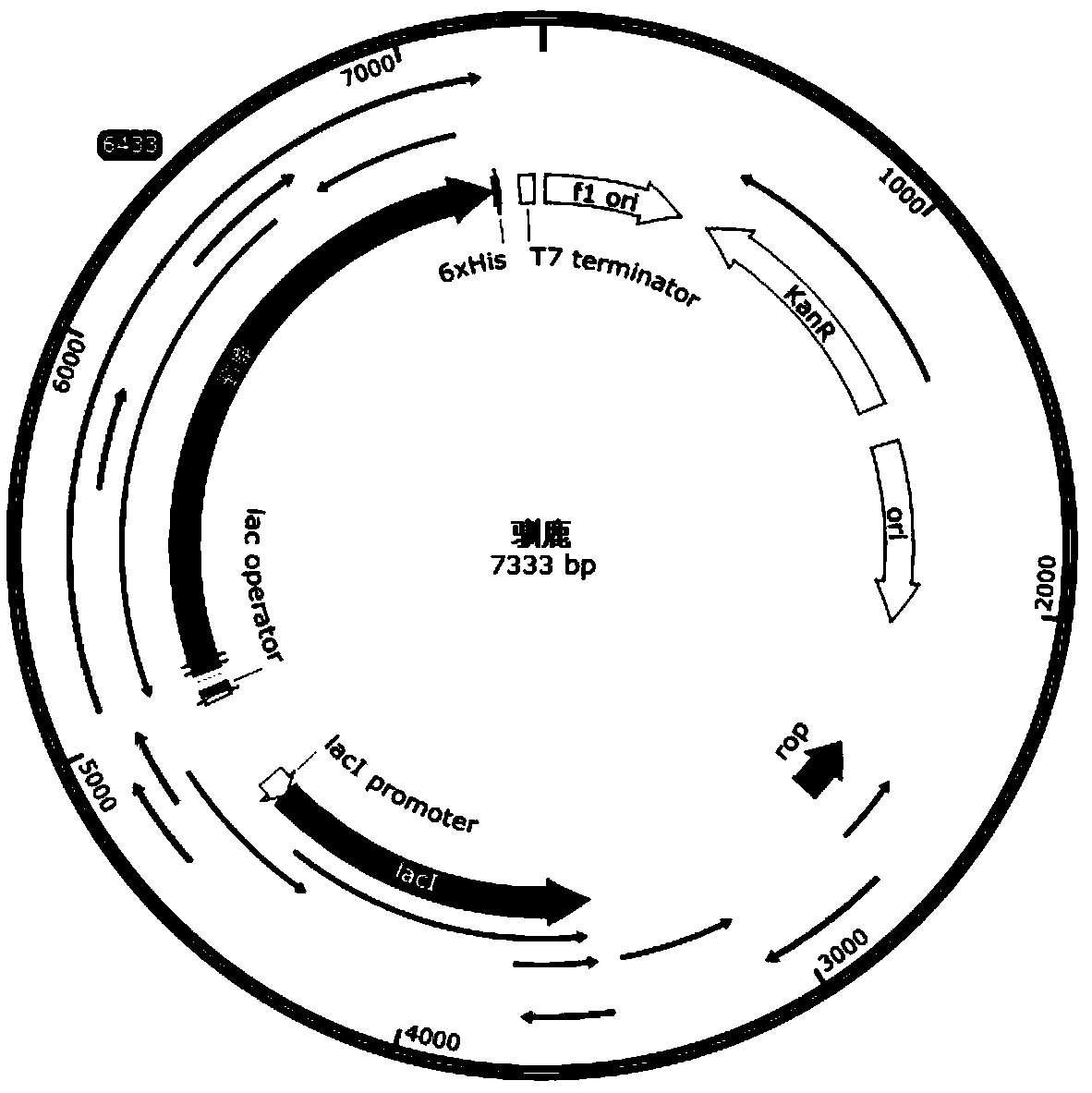

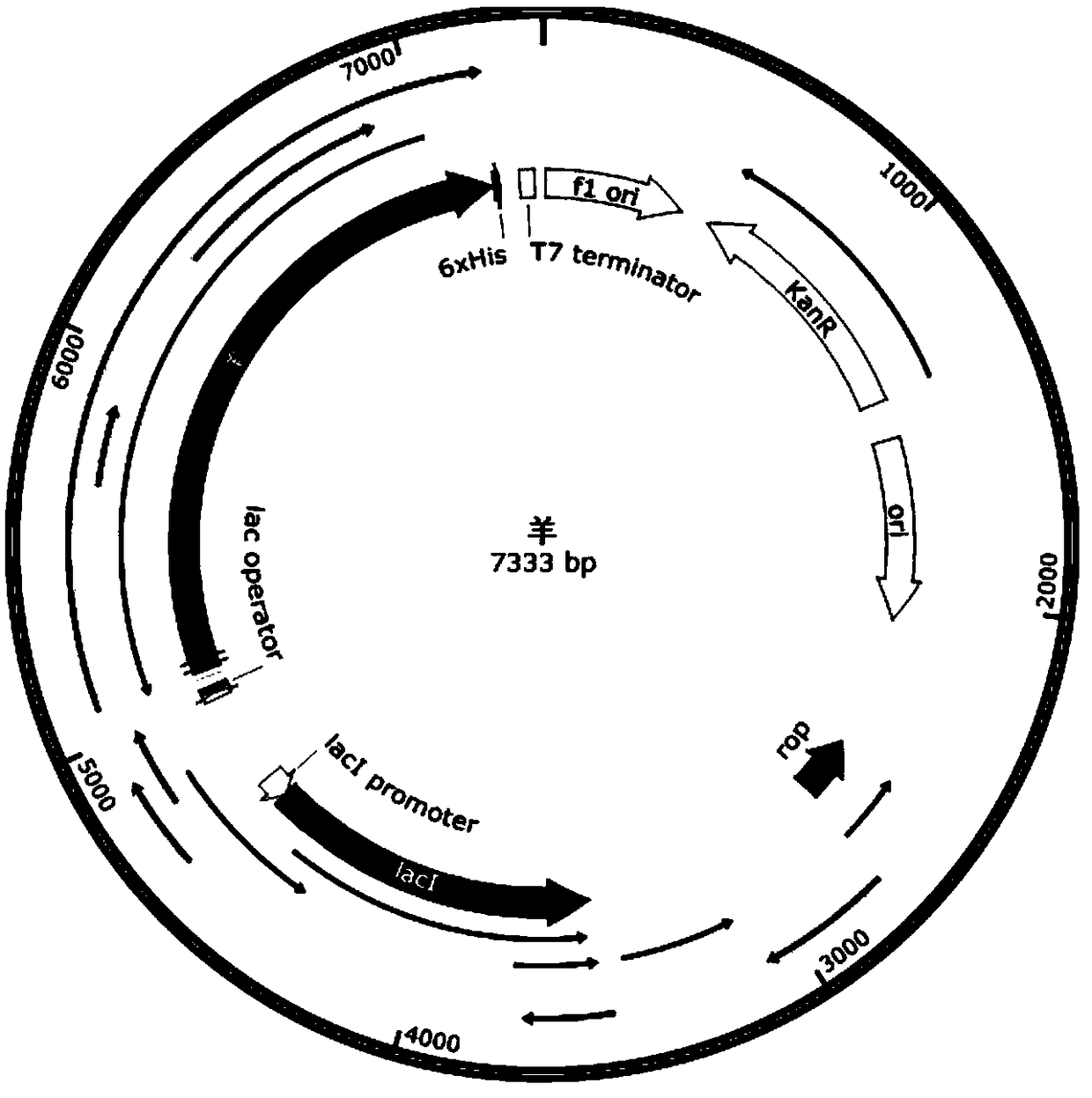

Construction and expression, separation and purification method of recombinant vector containing reindeer NADPH-cytochrome P450 reductase gene

A technology of cytochrome and recombinant vector, applied in the field of genetic engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 plasmid construction process:

[0020] According to the requirements of gibson technology, the primers needed in the present invention are designed (the 5F end of the primers has a homology arm of about 20-40bp), and the gene and the pET-28a carrier optimized according to the codon preference of Escherichia coli are linearized by PCR technology respectively. Then, add the linearized gene and vector into the gibson system, incubate, connect, transform E. coli DH5α, carry out plasmid amplification, pick a single clone, verify, and save the positive clone for future use.

Embodiment 2

[0021] Embodiment 2 expression vector transformation process:

[0022] Extract the plasmid from the above positive clone, take 200ng of the plasmid, mix it with 50μL of commercial Escherichia coli competent BL21(DE3), incubate on ice for 30min, then heat shock at 42°C for 45S, place it on ice for 2min, and then add 300μL of LB The culture medium was revived at 37°C for 1 hour, and spread on LB solid plate medium with kanamycin resistance (pET28a plasmid is kanamycin resistance). Cultivate overnight, pick a single clone for verification, and keep positive clones for future use.

Embodiment 3

[0023] Expression and purification of embodiment 3 protein:

[0024] 1) Seed liquid culture: Pick the above-mentioned BL21(DE3) strain containing the target plasmid, inoculate it into a small test tube containing 5 mL of LB liquid medium (Kan+, 100 μg / mL), and culture overnight at 37°C and 220 rpm as the seed liquid.

[0025] 2) Transplant: transfer the seed liquid into 800mL 2YT liquid medium (Kan+, 100μg / mL) at 1% inoculum amount, culture on a shaker at 37°C, 220rpm (about 4-6h) until the OD 600 is about 0.6- 0.8.

[0026] 3) Induction: lower the temperature of the shaker to 16°C, and after the temperature of the cultured bacterial solution is lowered, add isopropylthio-β-D-galactoside (IPTG) to a final concentration of 0.5mM to induce the expression of 14 -16h.

[0027] 4) Bacteria collection: After the expression is completed, collect the cultured bacteria solution into a bottle, pre-cool the centrifuge to 4° C., and centrifuge at 6000 rpm for 30 minutes.

[0028] 5) Cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com