Natural drying type offset lithographic paper bottom ink and preparation method thereof

A natural drying, offset paper technology, used in inks, household appliances, applications, etc., to achieve the effect of speeding up drying, reducing usage, and increasing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

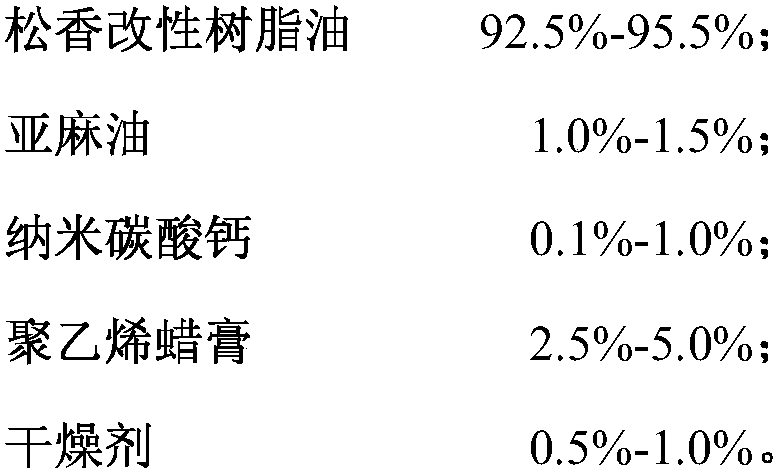

[0024] The natural drying type lithographic offset paper base ink of the present embodiment is made up of the following components by mass percentage:

[0025]

[0026]

Embodiment 2

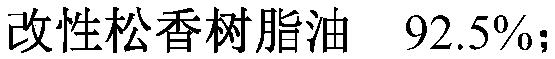

[0028] The natural drying type lithographic offset paper base ink of the present embodiment is made up of the following components by mass percentage:

[0029]

Embodiment 3

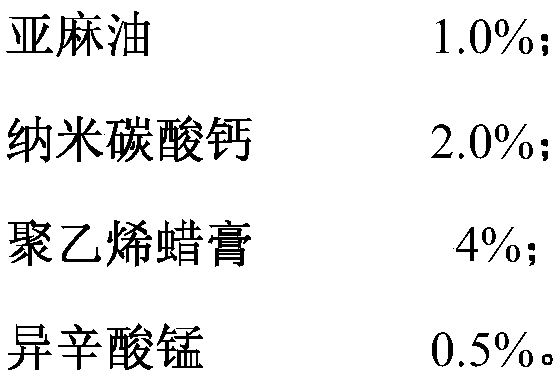

[0031] The natural drying type lithographic offset paper base ink of the present embodiment is made up of the following components by mass percentage:

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com