A kind of production method of gypsum board with retarder added

A paper-faced gypsum board and production method technology, applied in covering/lining, construction, building construction, etc., can solve the problems of production line capacity and product quality constraints, unsatisfactory retarder effect, too much influence on the strength of gypsum board, etc. , to achieve the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Retarder preparation: the content of bone glue, surfactant, and sodium tripolyphosphate are 0.02%, 0.03%, and 0.01% of the gypsum material (mass ratio).

[0022]Device settings:

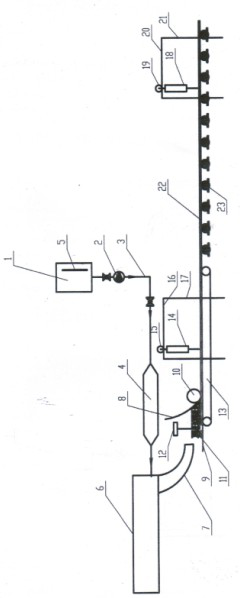

[0023]A level gauge 5 is installed on the retarder stock tank 1 and a retarder stock pump 2 is installed in the lower part of the retarder stock tank 1 through a pipeline, and passes through the retarder stock pipeline 3 and a static mixer 4 is connected, the static mixer 4 is connected with the mixer 6. A discharge port 7 is provided in the lower part of the mixer 6, and the retarder is transported to the bottom paper 9 of the face protection paper through the discharge port 7 to contact and fuse with the gypsum slurry 11. The upper part of the gypsum slurry 11 is equipped with an on-line detection device 12 for fluidity. The gypsum slurry 11 is transported forward through the solidification belt 13. A pressure roller 10 is installed on the upper part of the gypsum slurry 11, and the cover paper 8 is cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com