Rotary table type full-automatic labeling system of mini-type contactor

A micro contactor and turntable technology, which is applied to labeling machines, labels, conveyor objects, etc., can solve the problems of low accuracy, missed labeling, and inability to realize automatic labeling, so as to improve efficiency and reduce equipment costs. Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

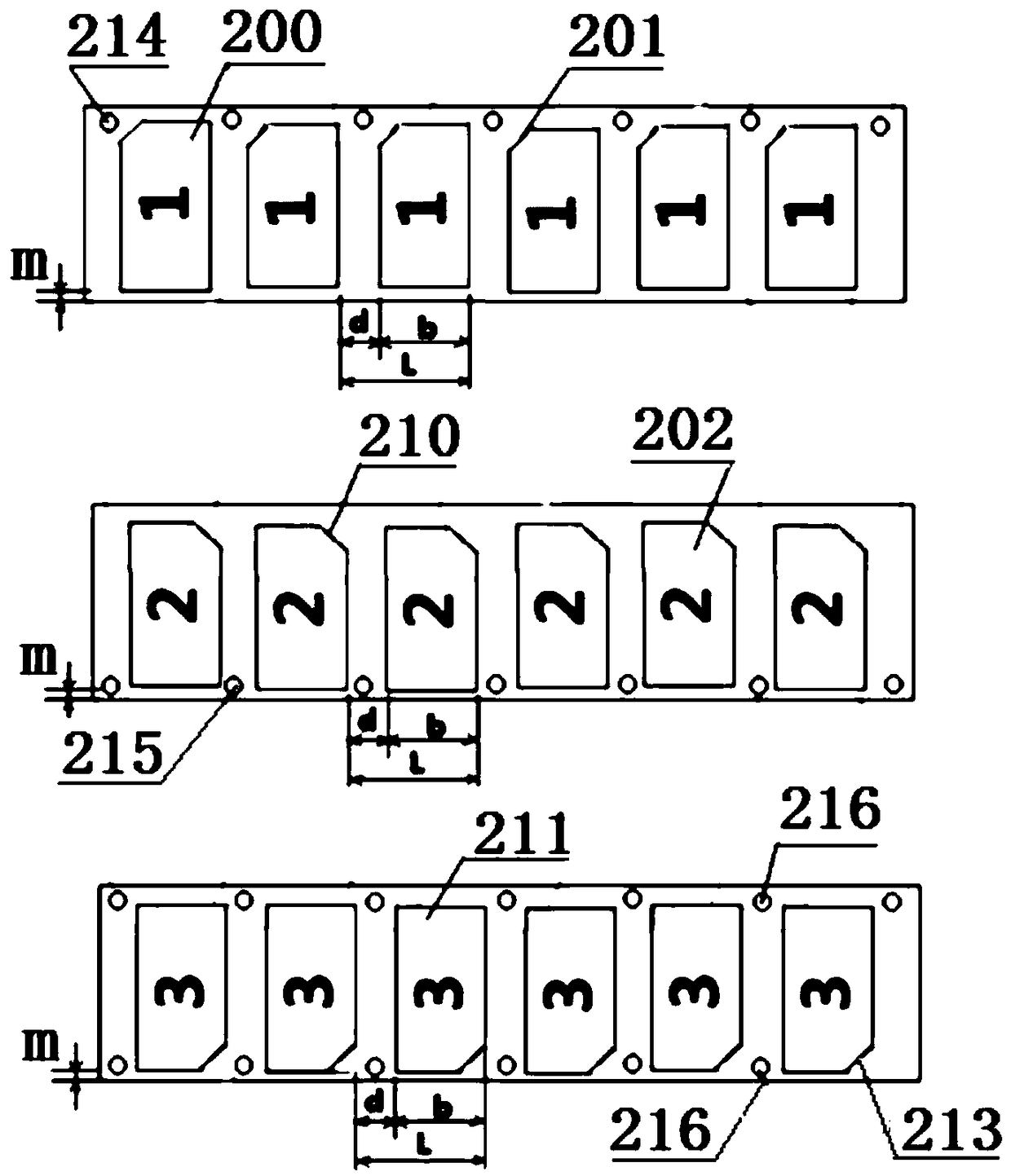

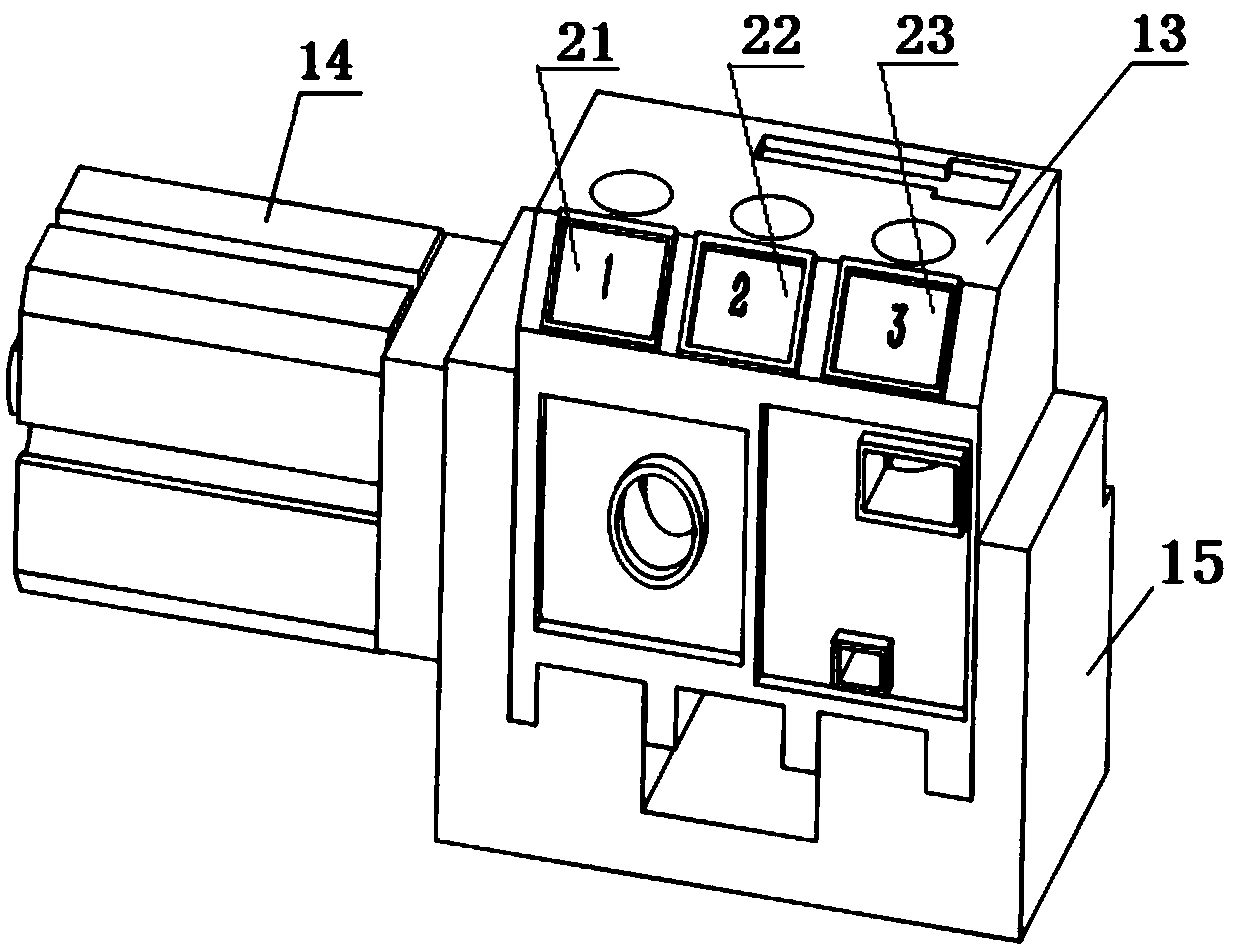

[0041] The existing miniature contactor is a "square" slot, and the labeling of "1 pole", "2 pole" and "3 pole" labels is completed manually. The present invention improves the existing "square" grooves into different chamfered grooves.

[0042] Such as figure 1 , is the matching mixed tape of the working object micro contactor of the present invention. The 1-pole label 200, the 2-pole label 202 and the 3-pole label 211 are respectively arranged at intervals on the glassine bottom paper of the label; the upper left corner of the 1-pole label 200 is provided with 1 Pole positioning mark 201, 2-pole positioning mark 210 is set on the upper right corner of 2-pole label 202, 3-pole positioning mark 213 is set on the lower right corner of 3-pole label 211; 1 pole is confirmed on the upper left front of 1-pole label 200 on the bottom paper of the tape The address detection hole 1 214 of the label 200; the address detection hole 2 215 for confirming the 2-pole label 202 is opened in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com