Three-stage wet rear axle assembly

A rear axle, wet technology, applied in the field of three-stage wet rear axle assembly, can solve the problem of having to transport the whole machine back to the company for replacement, shorten the service life of the vulnerable parts of the rear axle, and there is no more reasonable product available. and other problems, to achieve the effect of convenient and fast maintenance and maintenance, eliminating potential safety hazards and facilitating procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

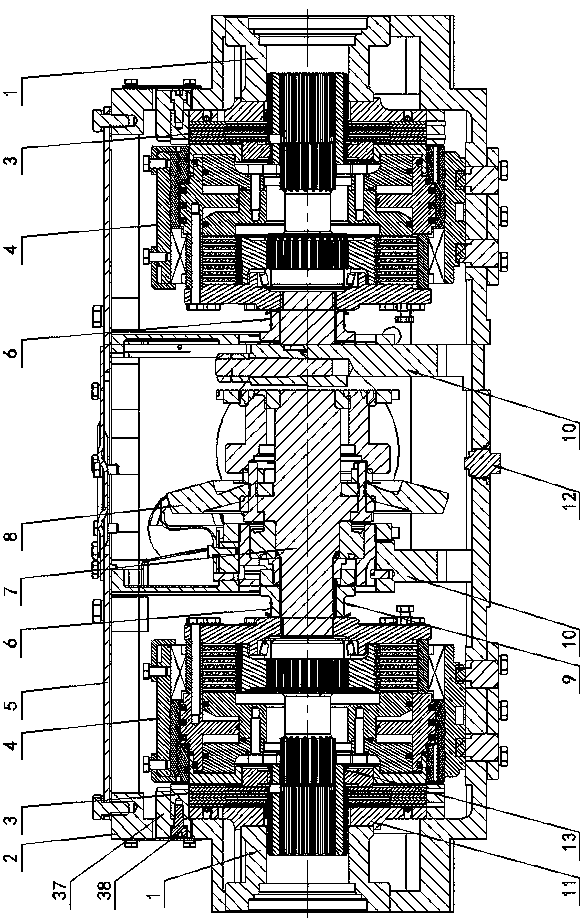

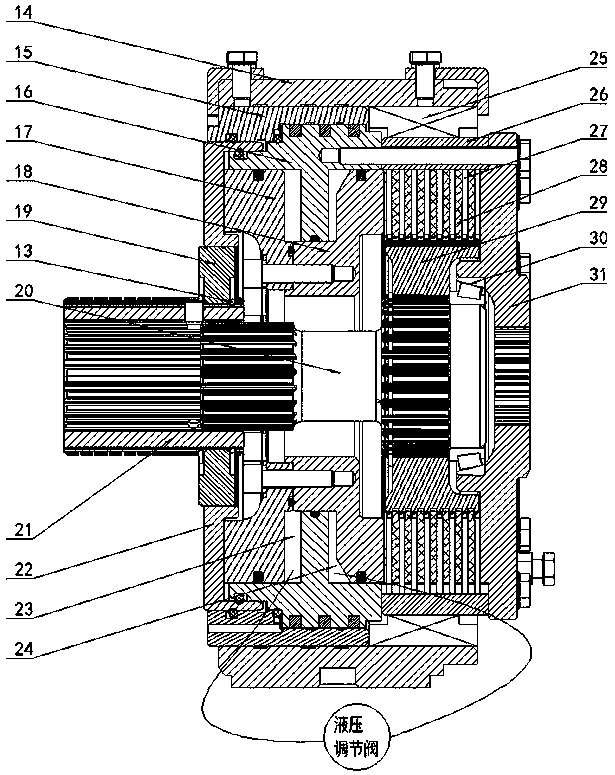

[0021] Figure 1 to Figure 4 Shown is a specific implementation of a three-stage wet rear axle assembly created by the present invention, which includes a rear axle housing 2, an upper cover 5, a rear axle shaft 7, and a large bevel gear 8 fixed on the rear axle shaft 7 , Left and right clutches 4, left and right brakes 3, the rear axle housing 2 is correspondingly fixed with left and right partitions 10, the left and right partitions 10 separate the inner cavity of the rear axle housing 2 into mutually connected wet central areas and left and right wet clutches In the braking zone, the rear axle shaft 7 is rotatably arranged on the left and right partitions 10, the left and right clutches 4 and the left and right brakes 3 are correspondingly installed in the left and right wet clutch braking zones, and the left and right clutches 4 are detachably connected to the rear axle shaft 7. The output ends on both sides of the rear axle housing 2 are correspondingly provided with a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com