Centralizing mechanism of lower ejector core rod for sand casting die

A technology of ejector rod and ejector core, applied in casting and molding equipment and other directions, can solve the problems of affecting work efficiency, time-consuming, and difficulty in resetting the lower core box, and achieve the advantages of increasing production steps, preventing the formation of dry sand, and changing the production rhythm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

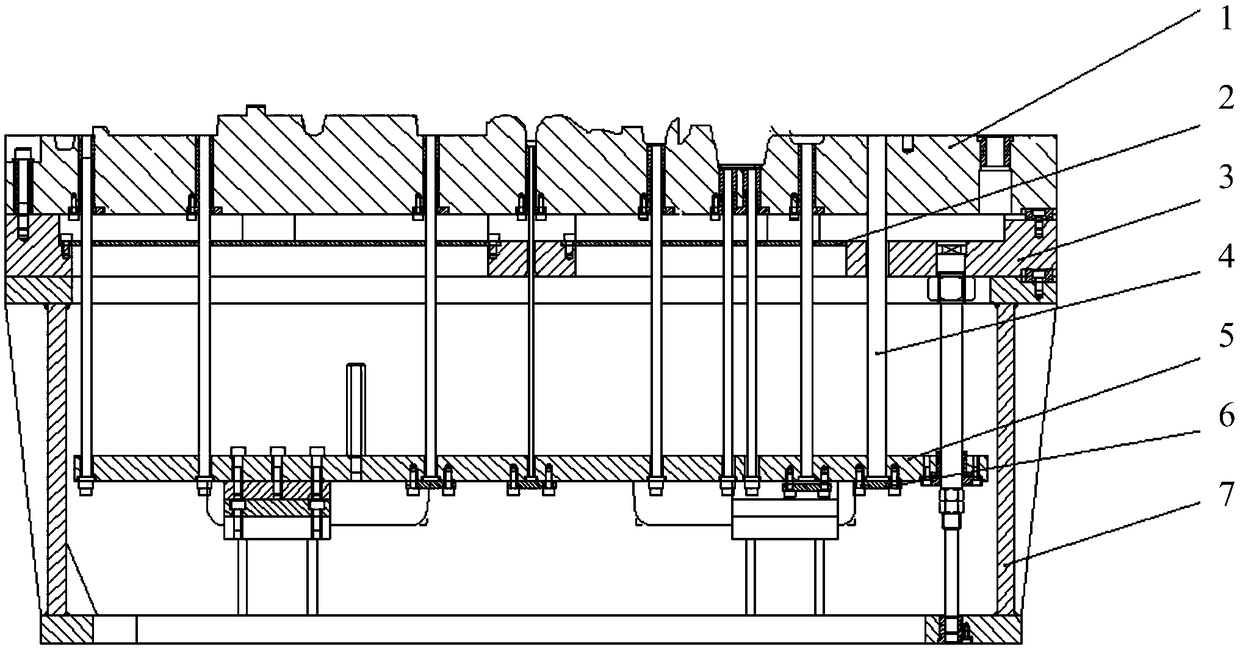

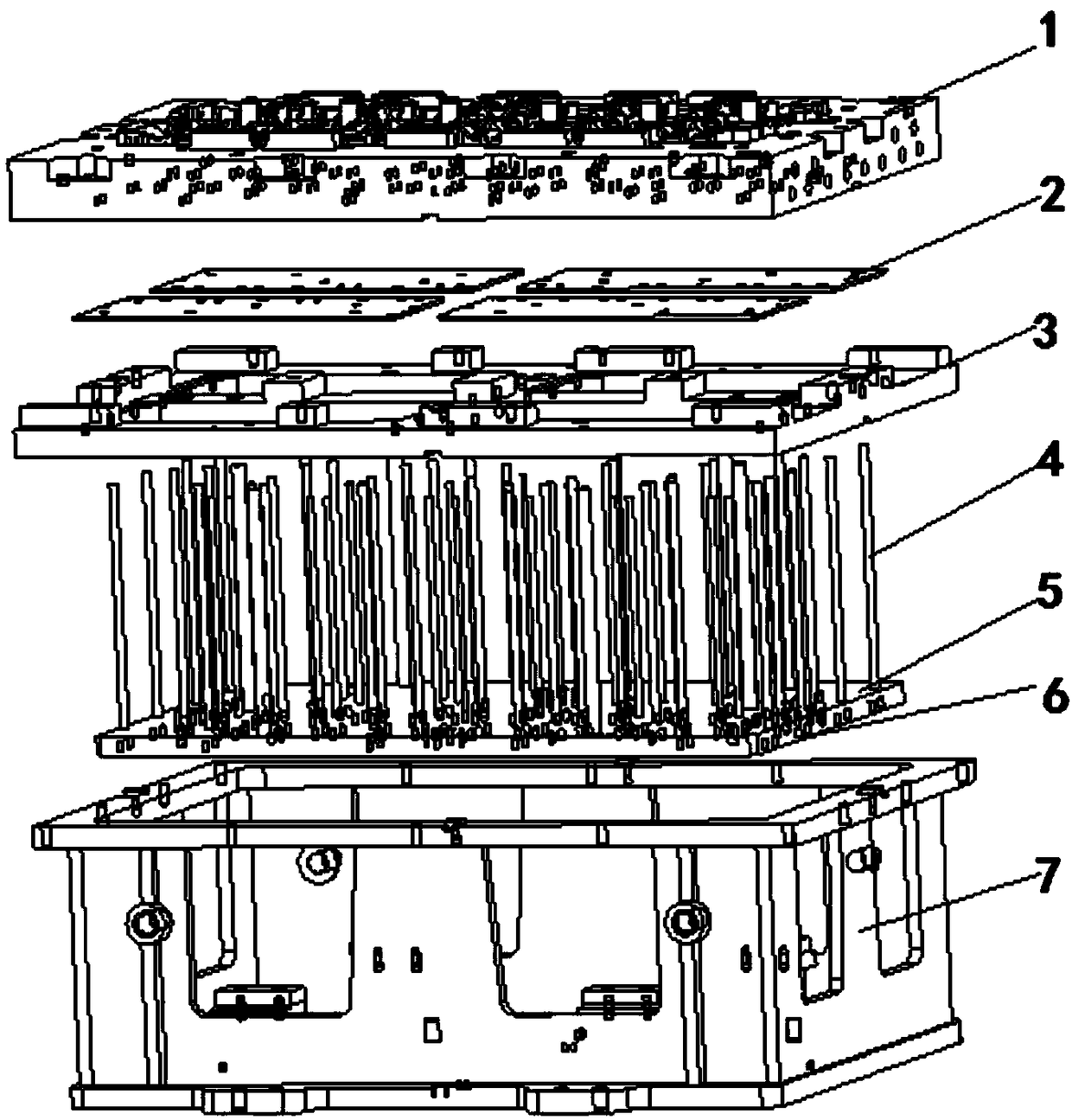

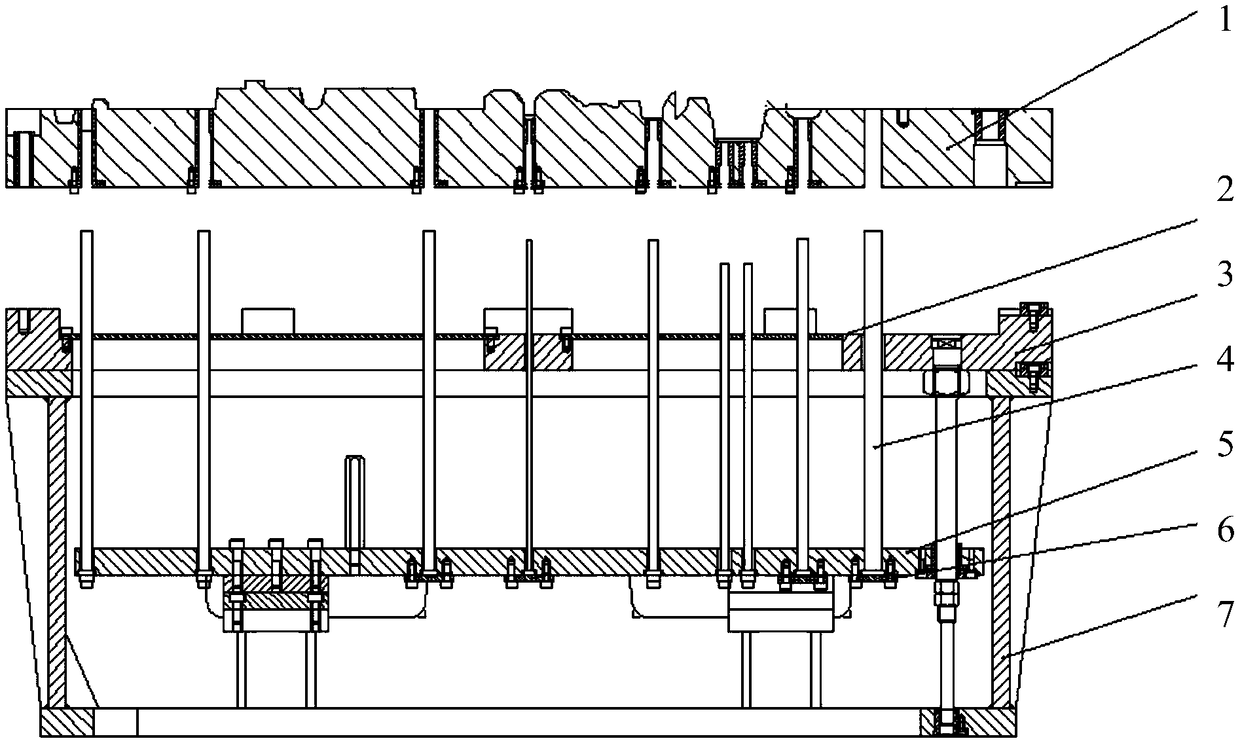

[0014] Such as Figure 1-3 As shown, a lower ejector rod straightening device includes a lower core box 1, a lower ejector rod guide plate 2, a lower core box fixing plate 3, a lower ejector rod 4, a lower ejector plate 5, and a lower ejector rod pressing plate 6. Bottom frame7.

[0015] The lower ejector rod 4 passes through the hole of the lower ejector core plate 5 from bottom to top, and the lower ejector rod pressing plate 6 is fixed at the joint between the lower ejector rod 4 and the lower ejector plate 5 by screws; the lower ejector rod is equipped with The lower top core plate 5 of 4 is integrally arranged on the support plate in the bottom frame 7; the lower core box fixing plate 3 is fixed on the upper plane of the bottom frame 7 by screws; the lower core rod guide plate 2 passes through the lower core rod 4 And fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com