Screening machine with automatic feeding function

An automatic feeding and screening machine technology, which is applied in the fields of filtering, solid separation, loading/unloading, etc., can solve the problems of ordinary screening equipment, such as labor time consumption and high price, so as to reduce the frequency of manual feeding, save costs, The effect of reducing labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

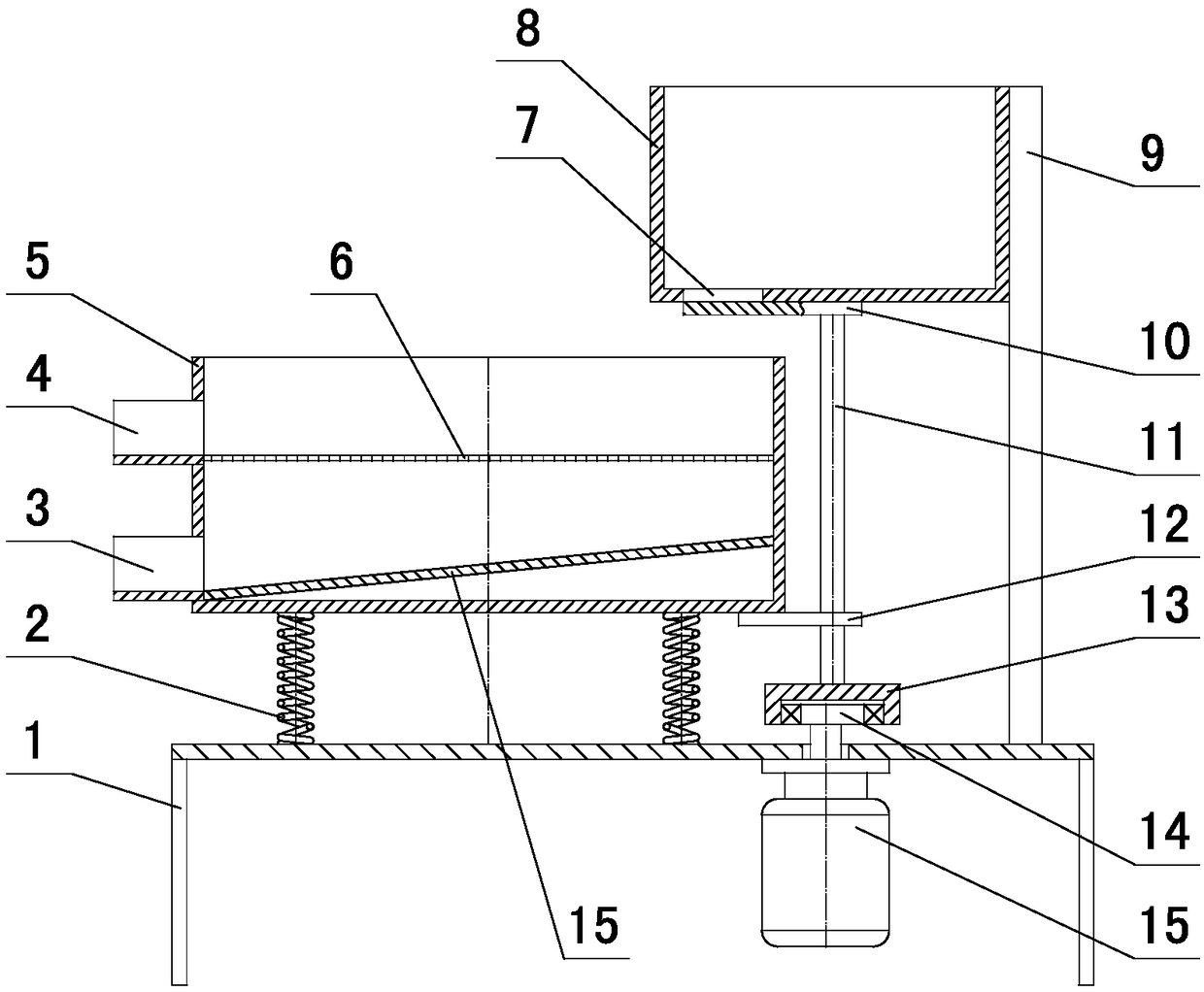

[0014] like figure 1 As shown, the automatic feeding screening machine includes a horizontally arranged workbench 1, a sieve body 5 is horizontally arranged above the workbench 1, and several compression springs 2 are arranged between the sieve body 5 and the workbench 1. The body 5 is installed on the workbench 1 through the compression spring 2, a screen 6 is arranged in the screen body 5, and a first discharge groove 4 is horizontally arranged on the left side of the screen body 5, and the first discharge groove 4 and the screen body 5 are connected and communicated, the first discharge chute 4 is located above the screen 6, the second discharge chute 3 is arranged below the first discharge chute 4, the second discharge chute 3 is connected to the sieve body 5, and the second The discharge trough 3 is located below the screen 6, a hopper 8 is arranged above the sieve body 5, a riser 9 is vertically arranged on the right side of the hopper 8, the hopper 8 is fixed on the ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com