Sweet fermented flour paste and preparation method thereof

A technology for sweet noodle sauce and dough, which is applied in the fields of food science, food preservation, and food ingredients as odor modifiers, etc., can solve the problems of sweet noodle sauce quality, taste impact, health impact, shortened shelf life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

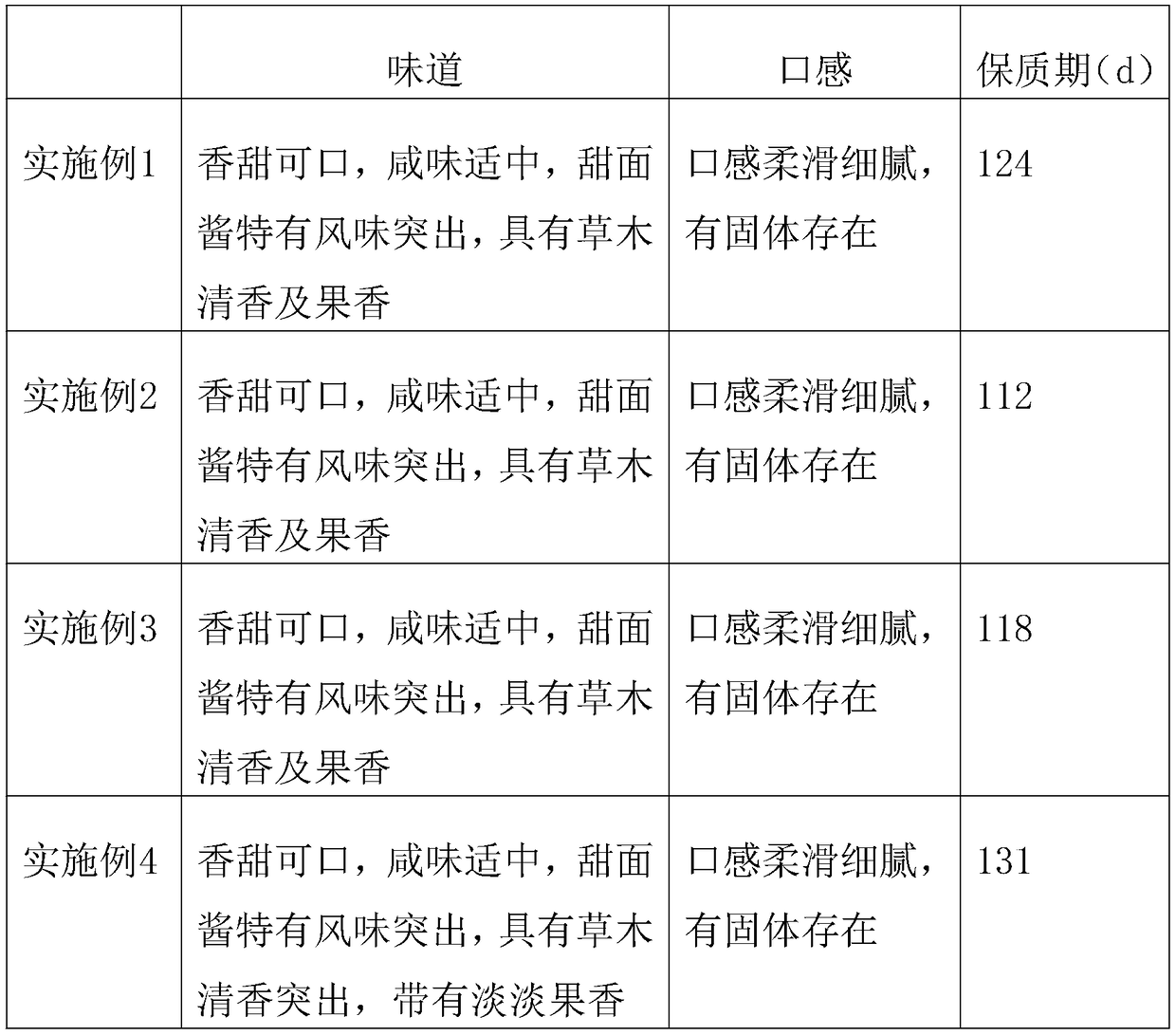

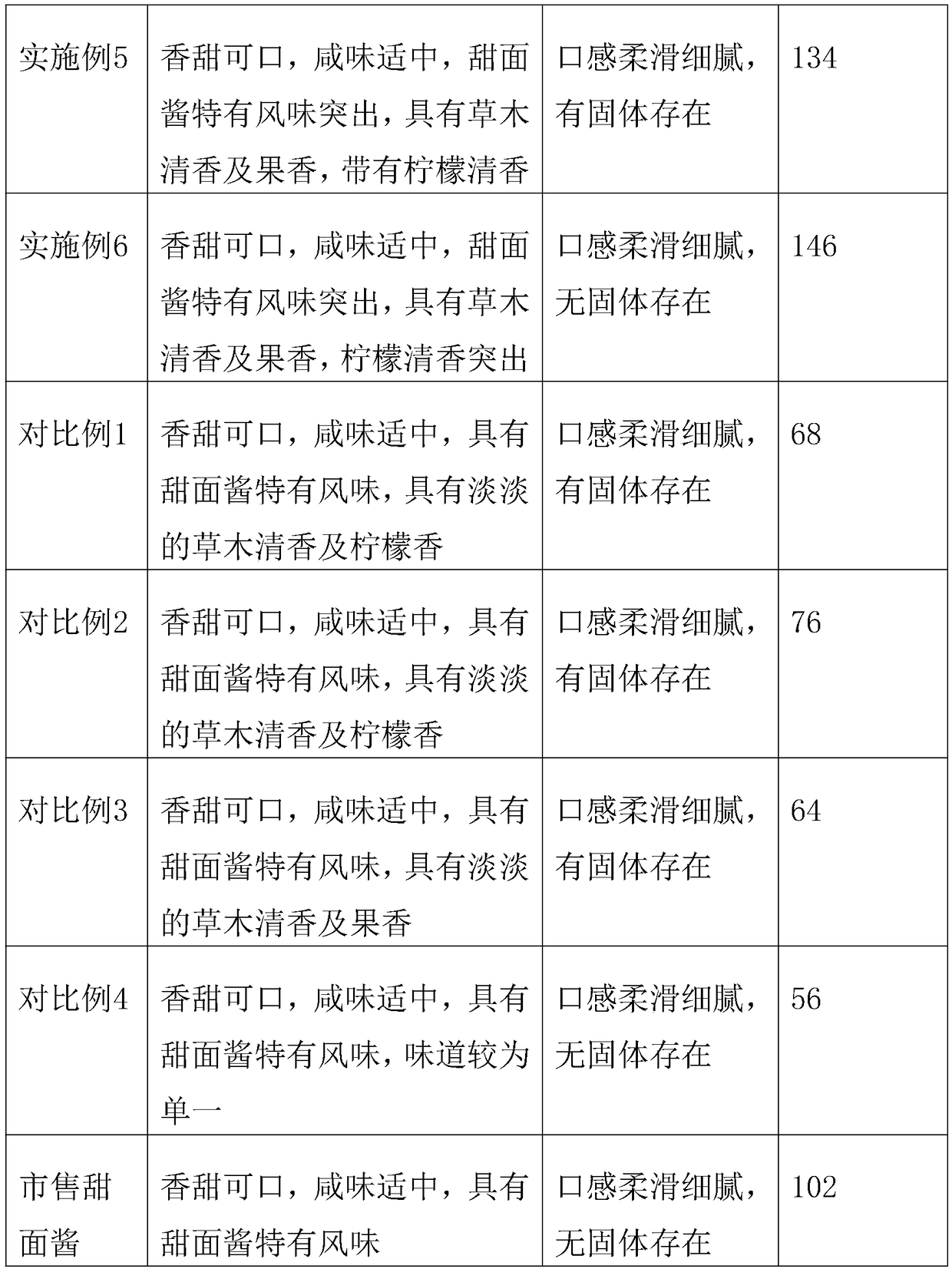

Examples

Embodiment 1

[0029] A kind of sweet noodle sauce, prepares by following method:

[0030] (1) Dough preparation: take flour, add 7.5% water and 1.75% yeast, knead at a speed of 175r / min for 20min, and leave to ferment for 75min at a humidity of 80% and a temperature of 30°C;

[0031] (2) Dough ripening: steam the fermented dough and cool to normal temperature;

[0032] (3) koji making: the steamed dough is broken into small pieces, inoculated with Aspergillus oryzae, left to ferment for 75h under the environment of humidity 90% and temperature 32.5° C. to obtain koji;

[0033] (4) Fermentation of unstrained spirits: Put the finished koji in a fermentation container, add salt water, adjust the overall salinity at 5%, add 9% thyme, and leave it to ferment for 22 days in an environment with a humidity of 80% and a temperature of 30°C;

[0034] (5) Grinding the sauce: Grind the fermented sauce grains finely, add 0.55% ionone, sterilize, add 5% lemon balm, and get final product.

[0035] Descr...

Embodiment 2

[0037] A kind of sweet noodle sauce, prepares by following method:

[0038] (1) Dough preparation: take flour, add 5% water, 0.5% yeast, knead at a speed of 150r / min for 25min, and leave to ferment for 100min at a humidity of 75% and a temperature of 25°C;

[0039] (2) Dough ripening: steam the fermented dough and cool to normal temperature;

[0040] (3) koji making: the steamed dough is broken into small pieces, inoculated with Aspergillus oryzae, left to ferment for 100h under the environment of humidity 85% and temperature 30° C., to obtain koji;

[0041] (4) Fermentation of unstrained spirits: place the finished koji in a fermentation container, add salt water, adjust the overall salinity to 4%, add 6% thyme, and leave it to ferment for 30 days in an environment with a humidity of 75% and a temperature of 27°C;

[0042] (5) Grinding the sauce: grind the fermented sauce grains finely, add 0.1% ionone, sterilize, add 2% lemon balm, and get final product.

[0043] Described...

Embodiment 3

[0045] A kind of sweet noodle sauce, prepares by following method:

[0046](1) Dough preparation: take flour, add 10% water, 3% yeast, knead at a speed of 200r / min for 15min, and leave to ferment for 50min in an environment with a humidity of 85% and a temperature of 35°C;

[0047] (2) Dough ripening: steam the fermented dough and cool to normal temperature;

[0048] (3) koji making: the steamed dough is broken into fritters, inoculated with Aspergillus oryzae, left to ferment for 50 hours under the environment of humidity 95% and temperature 35°C to obtain koji;

[0049] (4) Fermentation of unstrained spirits: put the finished koji in a fermentation container, add salt water, adjust the overall salinity at 6%, add 12% thyme, and leave it to ferment for 15 days under an environment with a humidity of 85% and a temperature of 33°C;

[0050] (5) Grinding the sauce: grind the fermented sauce grains finely, add 1% ionone, sterilize, add 8% lemon balm, and get ready.

[0051] Des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com