Efficient energy saving pump

A high-efficiency energy-saving, pump body technology, applied in the direction of pumps, pump devices, liquid variable capacity machinery, etc., can solve the problems of energy loss of liquid media, difficulty in generating multiple flow rates, and speed vector differences, and achieve the goal of reducing energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

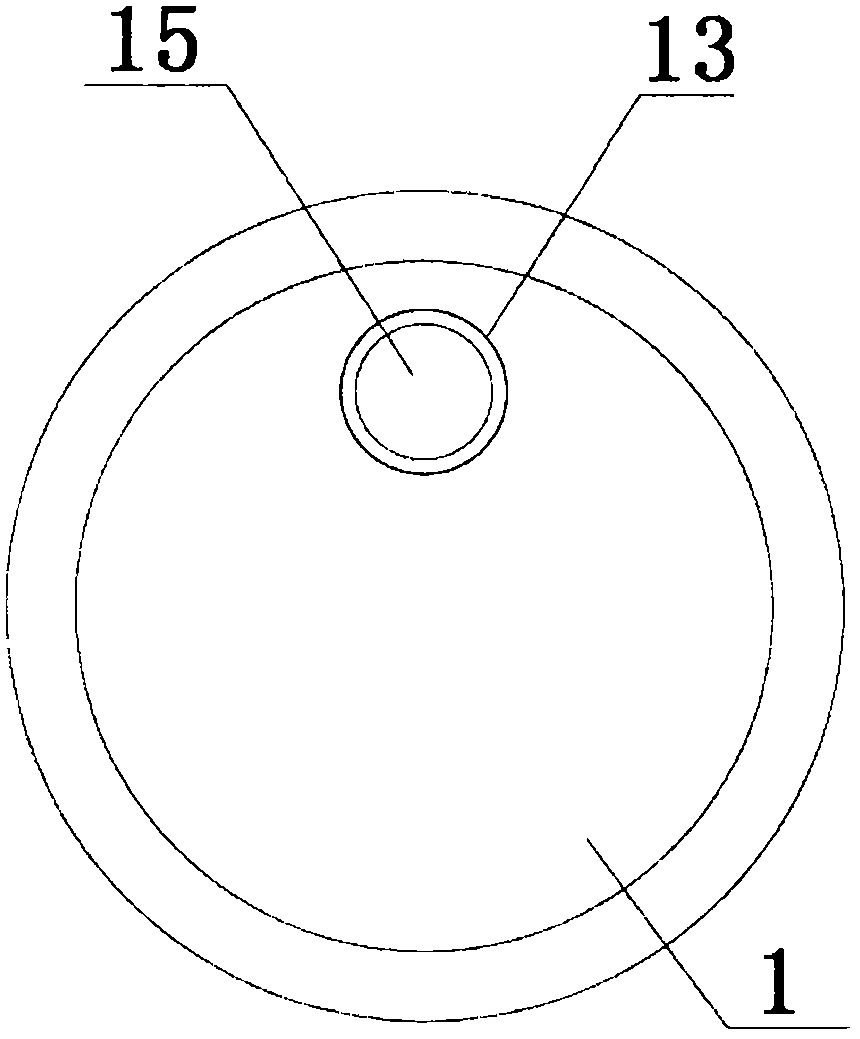

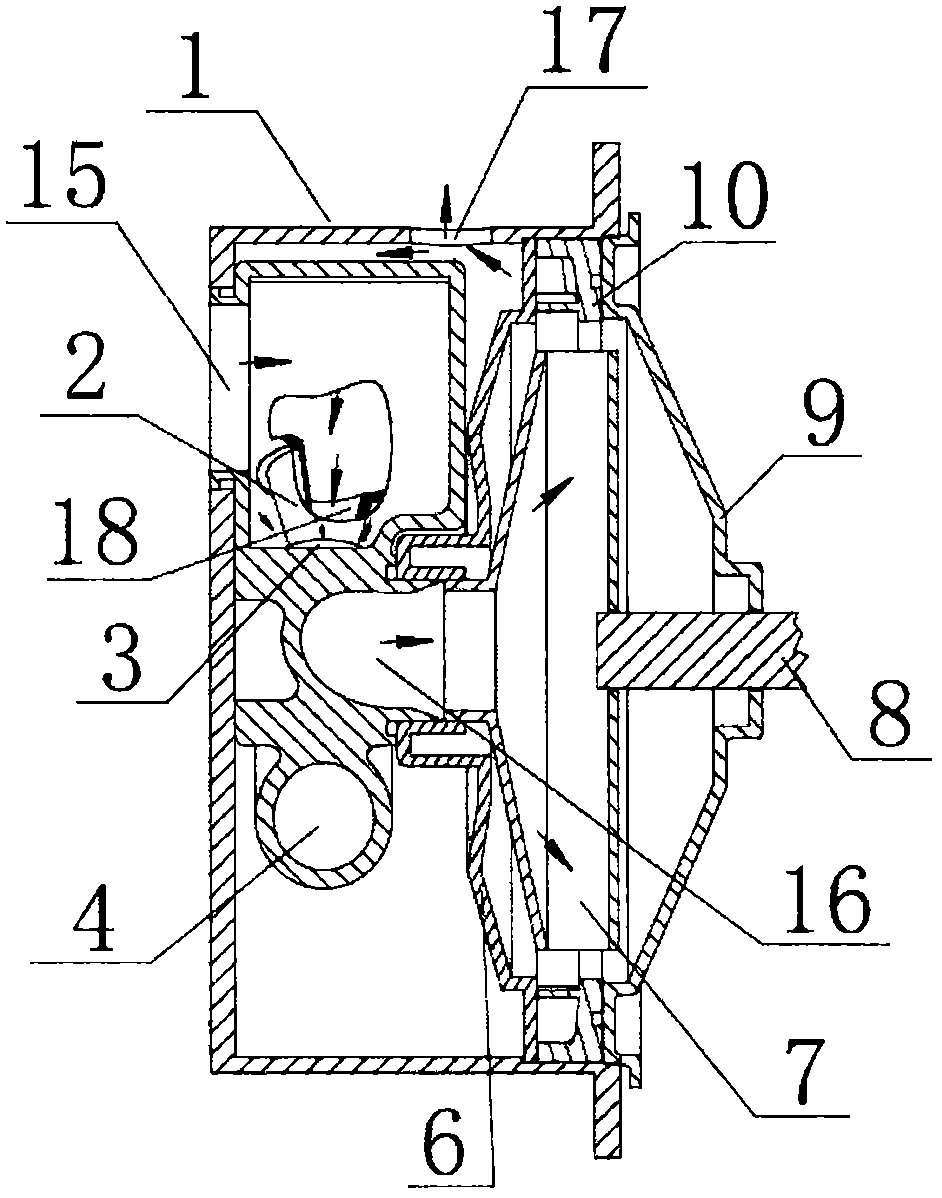

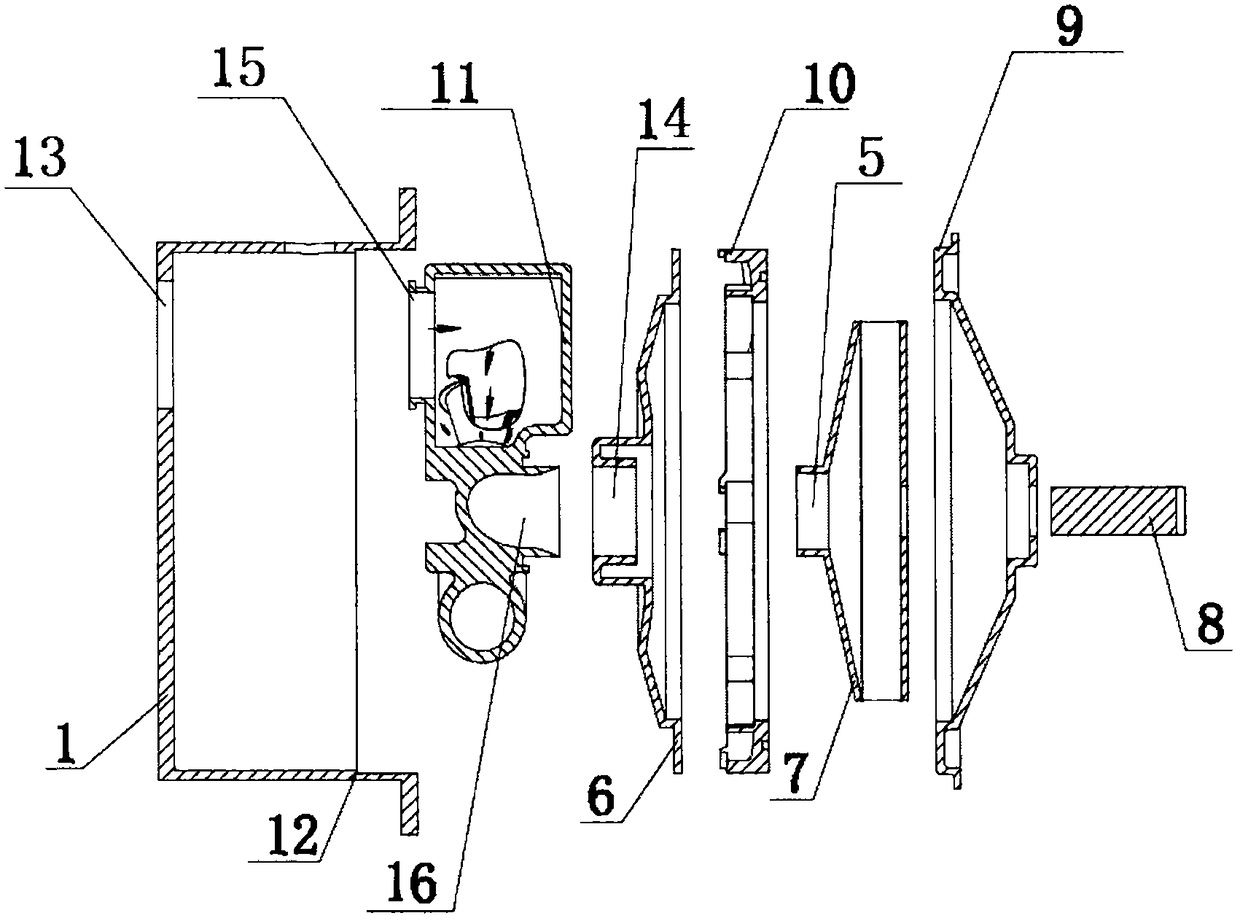

[0035] The structure of the high-efficiency energy-saving pump of the present invention is shown in Figure 1-Figure 5 shown. The pump body 1 is cylindrical with an opening 12 on one side, and a pump body inlet 13 is provided near the top of the pump body 1 . The opening 12 of the pump body 1 is sequentially equipped with a flow channel body 11, an inner swirl cover 6, a deflector plate 10 and an impeller 7 from the inside to the outside, and is fastened by the outer swirl cover 9 at the outermost end to form a whole.

[0036] A channel body inlet 15 is provided above the channel body 11 , which is engaged with the pump body inlet 13 . The flow channel body 11 is provided with a conical nozzle 2 with a large outside and a small inside. The other end of the spray pipe 3 is connected with a radial space mixing chamber 4 which is radially annular. The port of the mixing chamber 4 in the radial space is the outlet 16 of the mixing chamber, and the outlet 16 of the mixing chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com