An ultra-large and ultra-wide double-combined I-shaped steel beam and its segmented installation method

A technology of I-beam and I-beam, applied in the field of production and manufacturing, can solve the problems affecting the construction progress and construction quality of the project, restricting the coordinated development of the steel structure quality, and the sporadic components cannot be prefabricated in the factory, so as to improve the quality of the connection. , Reduce the investment of equipment cost and improve the effect of connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

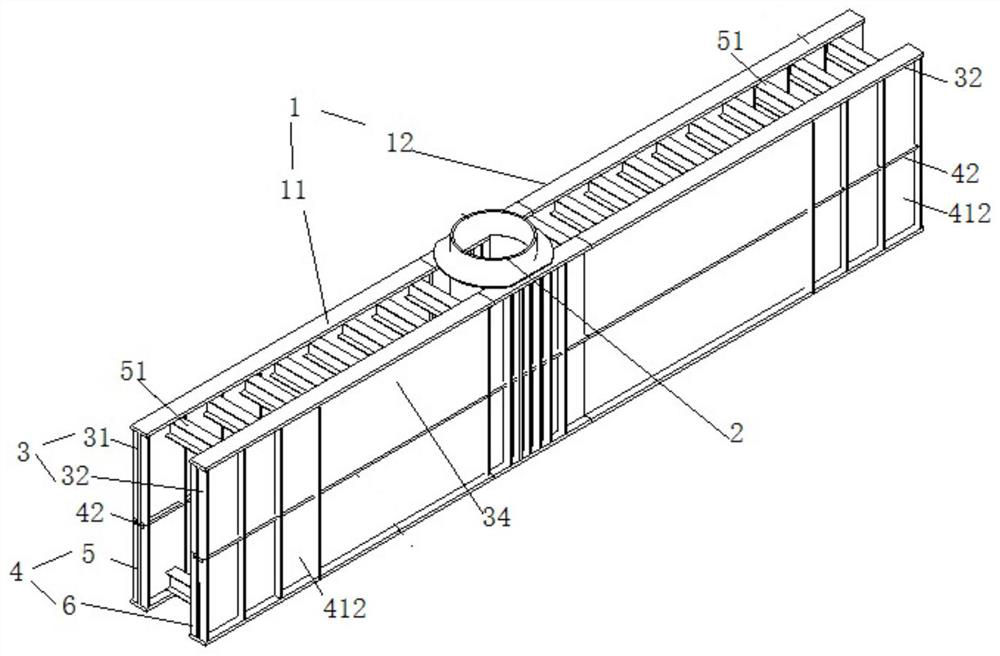

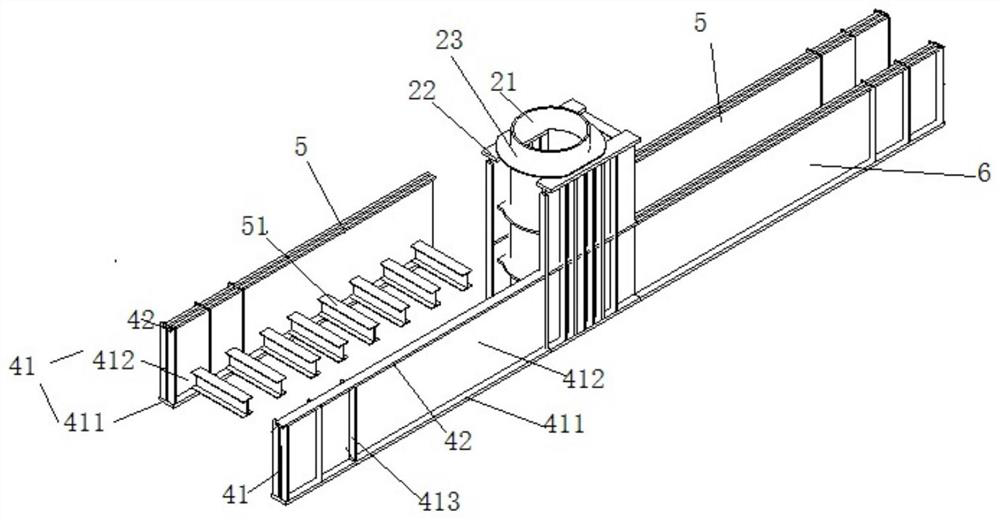

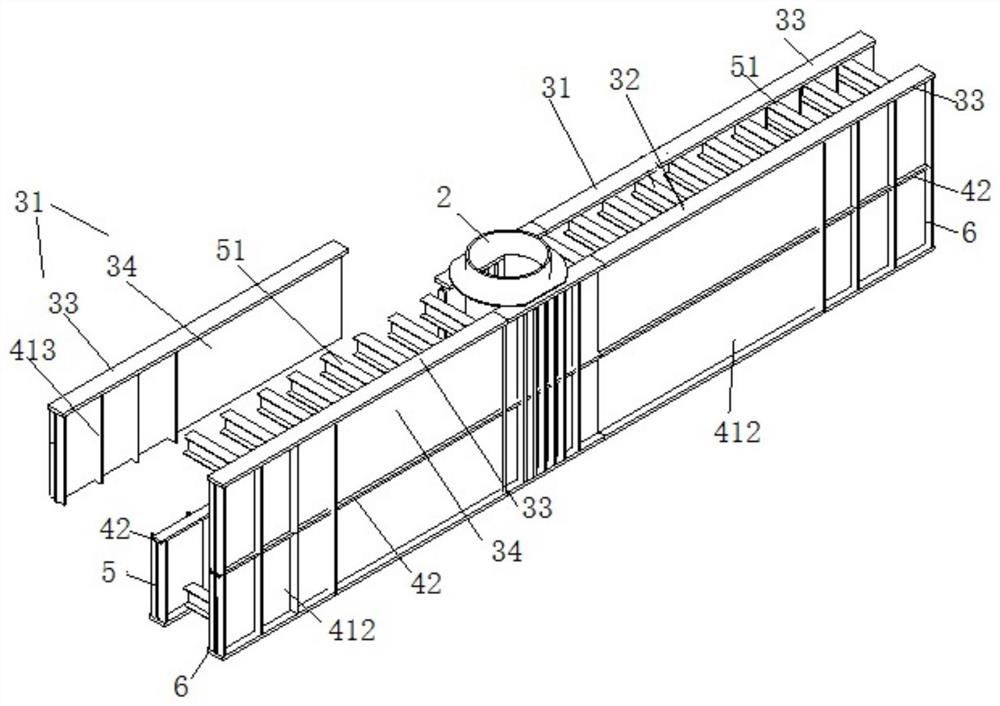

[0037] Such as Figure 1 to Figure 3 A super-large and ultra-wide double-combined I-beam beam shown includes: a double-combined I-beam 1 and a column foot 2, and the double-combined I-beam 1 is provided with a left-hand combined I-beam 11 and the right combination I-beam 12, the left combination I-beam 11 and the right combination I-beam 12 are equipped with an upper T-shaped section 3 and a lower I-shaped steel section 4, and the upper T-shaped section 3 The first T-shaped section 31 and the second T-shaped section 32 are arranged in the center, and the first segmented I-shaped steel 5 and the second segmented I-shaped steel 6 are arranged in the lower I-shaped steel section 4, and the first segmented I-shaped steel 6 is provided. A section I-beam 5 is provided with a horizontal connection working steel 51, and the first section I-beam 5 and the second section I-beam 6 are connected by beam bottom anchor bolts and horizontal connection work steel 51 to form a fixed Frame str...

Embodiment 2

[0045] Such as Figure 1 to Figure 3 A super-large and ultra-wide double-combined I-beam beam shown includes: a double-combined I-beam 1 and a column foot 2, and the double-combined I-beam 1 is provided with a left-hand combined I-beam 11 and the right combination I-beam 12, the left combination I-beam 11 and the right combination I-beam 12 are equipped with an upper T-shaped section 3 and a lower I-shaped steel section 4, and the upper T-shaped section 3 The first T-shaped section 31 and the second T-shaped section 32 are arranged in the center, and the first segmented I-shaped steel 5 and the second segmented I-shaped steel 6 are arranged in the lower I-shaped steel section 4, and the first segmented I-shaped steel 6 is provided. A section I-beam 5 is provided with a horizontal connection working steel 51, and the first section I-beam 5 and the second section I-beam 6 are connected by beam bottom anchor bolts and horizontal connection work steel 51 to form a fixed Frame str...

Embodiment 3

[0057] Such as Figure 1 to Figure 3 A super-large and ultra-wide double-combined I-beam beam shown includes: a double-combined I-beam 1 and a column foot 2, and the double-combined I-beam 1 is provided with a left-hand combined I-beam 11 and the right combination I-beam 12, the left combination I-beam 11 and the right combination I-beam 12 are equipped with an upper T-shaped section 3 and a lower I-shaped steel section 4, and the upper T-shaped section 3 The first T-shaped section 31 and the second T-shaped section 32 are arranged in the center, and the first segmented I-shaped steel 5 and the second segmented I-shaped steel 6 are arranged in the lower I-shaped steel section 4, and the first segmented I-shaped steel 6 is provided. A section I-beam 5 is provided with a horizontal connection working steel 51, and the first section I-beam 5 and the second section I-beam 6 are connected by beam bottom anchor bolts and horizontal connection work steel 51 to form a fixed Frame str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com