Caramel color production process

A production process, caramel color technology, applied in azo dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of low color rate, easy over-dehydration, formation of precipitation, etc., to improve color rate, protect the environment, save money energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment provides a kind of caramel production process, comprising:

[0026] 1. Use 2M 3 75% fructose syrup (reducing sugar content 95%, fructose content 42%, pH value 4.8), 3.60 tons, add to reactor 3M 3 Open the exhaust valve to heat the steam valve, close the feed valve, and start the reactor to stir;

[0027] 2. Close the exhaust valve when the temperature in the reactor reaches 110°C, turn off the heating steam when the temperature continues to rise to 145°C, stop heating, observe the pressure of the reactor at 0.02MPa and start calculating the reaction time.

[0028] 3. Take a sample from the sampling valve and check that the pH value is 4.7, add 250ml of 10% edible NaOH solution with the alkali adding device, and measure the pH value after 5 minutes to be 6.5, stop adding alkali, and measure the pH value to be 6.35, 6.32, and 6.40 every half hour , 6.30, pay attention to pH adjustment must add alkali after the temperature rises;

[0029] 4. After...

Embodiment 2

[0034] The present embodiment provides a kind of caramel production process, comprising:

[0035] 1. Use 2M 3 75% fructose syrup (reducing sugar content 95%, fructose content 42%, pH value 4.8), 3.60 tons, using microwave heating to make it react, set the parameters of microwave heating: power 500W, heating time 1min;

[0036] 2. Take a sample from the sampling valve and check that the pH value is 4.7, and add 10% Na with an alkali adding device 2 CO 3 Solution 250ml, after 5 minutes, the measured pH value is 6.0, stop adding alkali, pay attention to pH adjustment must add alkali after the temperature rises;

[0037] 4. After reacting for 1.5 hours, test whether there is precipitation in salt water, measure the color rate based on experience, and stop the reaction when the color rate is estimated to no longer increase.

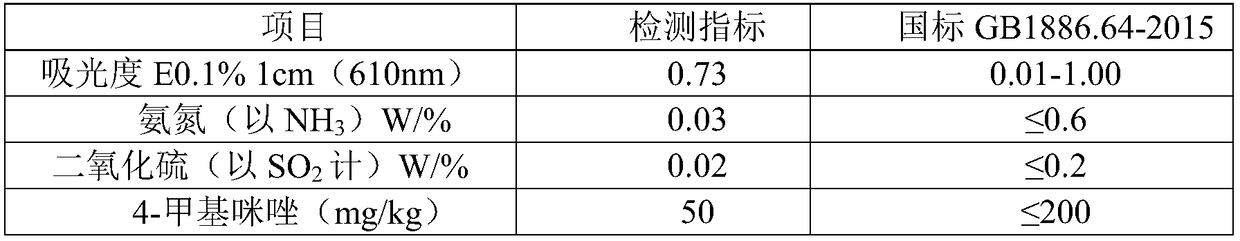

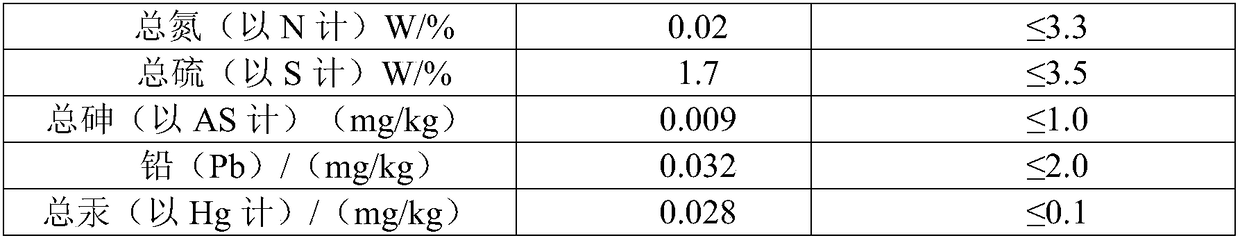

[0038] 5. Open the discharge valve to discharge into the cooling pool, add 10% edible citric acid, and adjust the pH to 4.47. The physical and chemical in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com