Intelligent control type environment-friendly automobile material loading system and method

A charging system and intelligent control technology, applied in conveyor control devices, loading/unloading, transportation and packaging, etc., can solve problems such as low intelligence, error-prone, and complicated manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

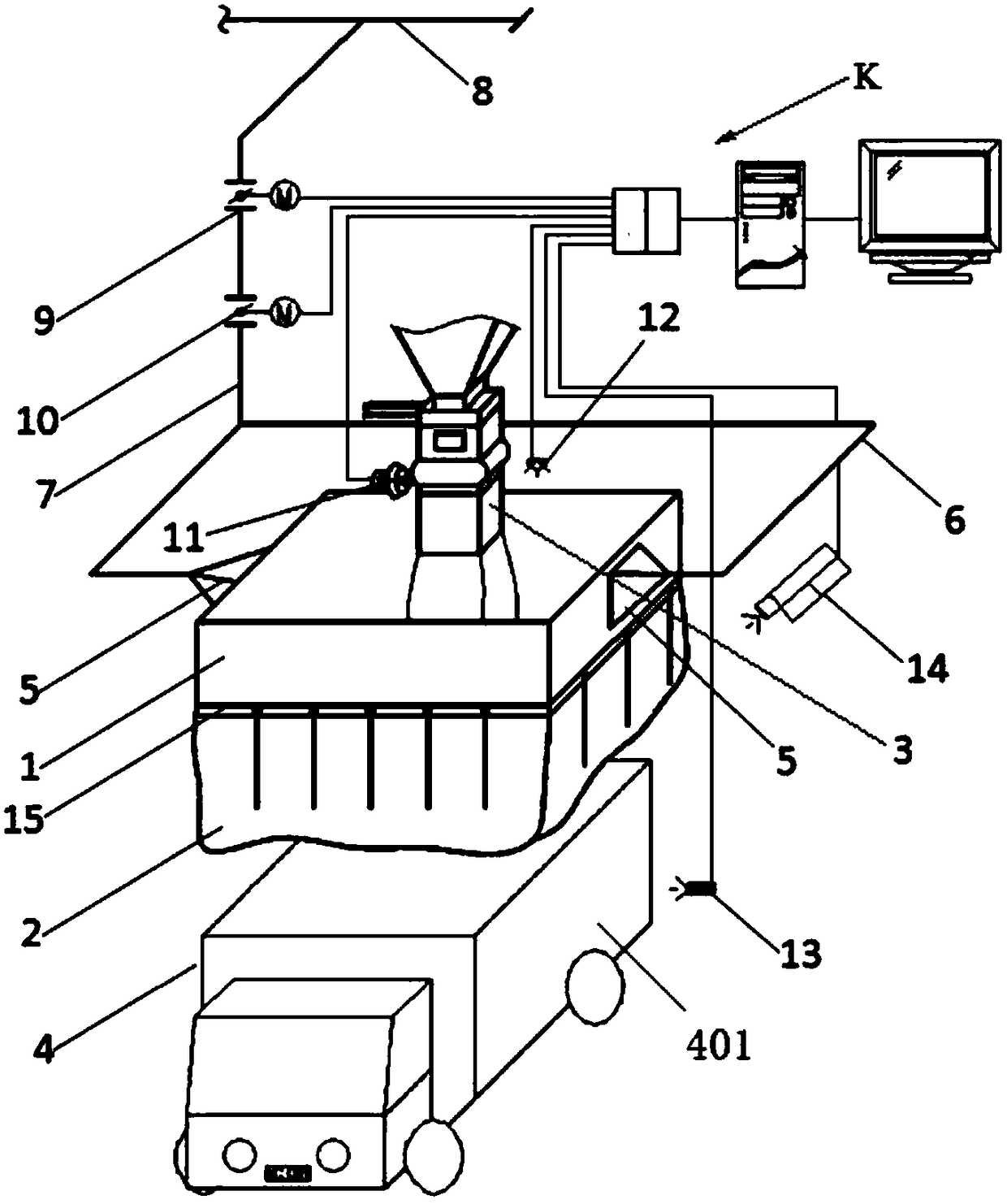

[0085] Such as figure 1 As shown, an intelligent control environment-friendly car charging system includes a partial airtight cover 1, a dust curtain 2, an ash chute 3 and a car 4. Wherein the bottom of partial airtight cover 1 is connected with dust curtain 2 around. The ash chute 3 is installed on the top of the partial airtight cover 1 and the ash chute 3 communicates with the inside of the partial airtight cover 1 . Automobile 4 is provided with automobile loading box 401. The car loading box 401 is located below the dust curtain 2 .

[0086] The system also includes dust removal interfaces 5 arranged on both sides of the partial airtight cover 1 . The system also includes a dust removal branch pipe 6 , a dust removal main pipe 7 and a dust collector inlet main pipe 8 . The dust removal branch pipes 6 drawn from the dust removal interfaces 5 on both sides of the partial airtight cover 1 are connected to the dust collector inlet main pipe 8 via the dust removal main pip...

Embodiment 2

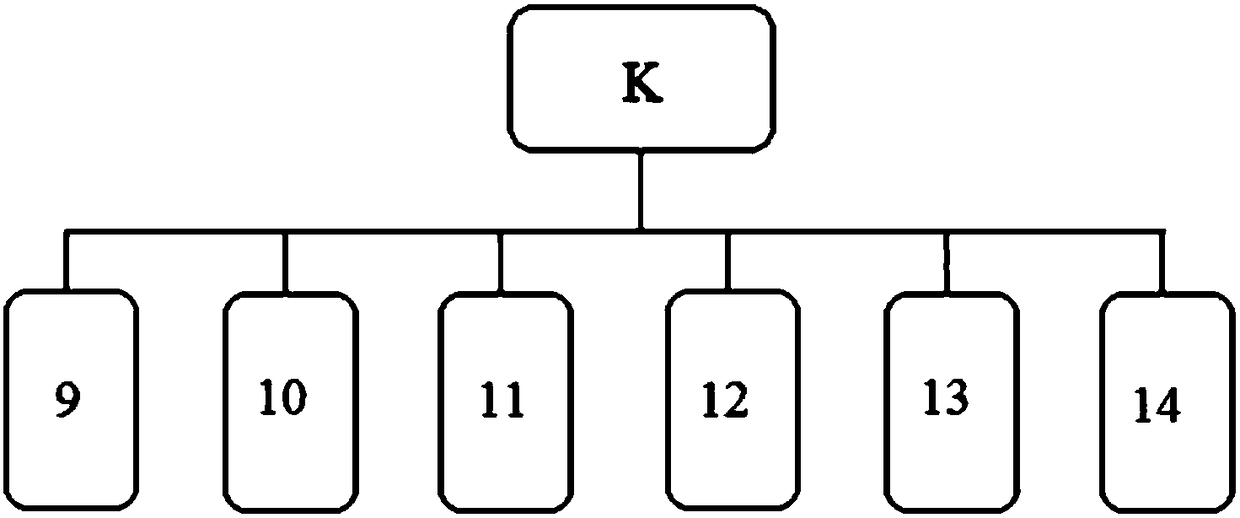

[0093] Embodiment 1 is repeated, except that the system further includes a vehicle identification device 14 arranged behind the partial airtight cover 1 . The control system K is connected with the switch type electric butterfly valve 9, the adjustable type electric butterfly valve 10, the dust discharge valve 11, the dust concentration detector 12, the position detection device 13 and the vehicle identification device 14, and controls the switch type electric butterfly valve 9, the adjustable type electric butterfly valve 10 and the operation of the ash discharge valve 11.

Embodiment 3

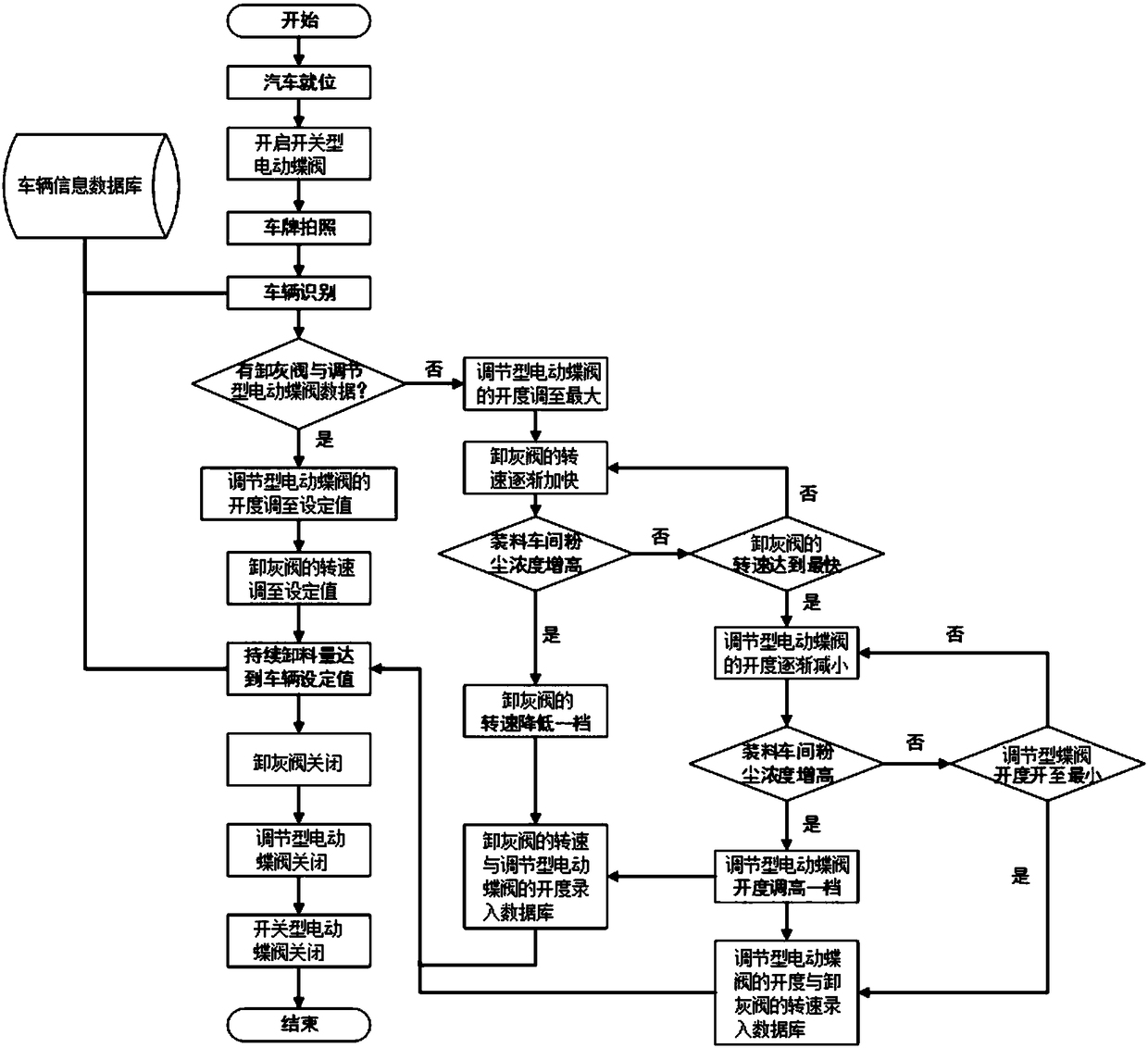

[0095] An intelligent control environment-friendly automobile charging method, using the system in embodiment 1, the method may further comprise the steps:

[0096] 1) The control system K judges whether the automobile 4 stops at a designated position in the unloading room through the position detection device 13;

[0097] 2) After the position detection device 13 detects that the car 4 is in place in the unloading room, the on-off electric butterfly valve 9 is opened, and the control system K adjusts the opening of the adjustable electric butterfly valve 10 and the ash discharge valve 11 to complete the car 4 loading :

[0098] Among them, the control system K adjusts the opening of the adjustable electric butterfly valve 10 and the ash discharge valve 11, and the completion of the car 4 loading is as follows:

[0099] ①The control system K adjusts the opening of the adjustable electric butterfly valve 10 to the maximum, and controls the speed of the ash discharge valve 11 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com