Feeding method of steel bar feeding machine

A technology of feeder and steel bar, which is applied in the field of feeder feeding and steel bar feeding machine feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

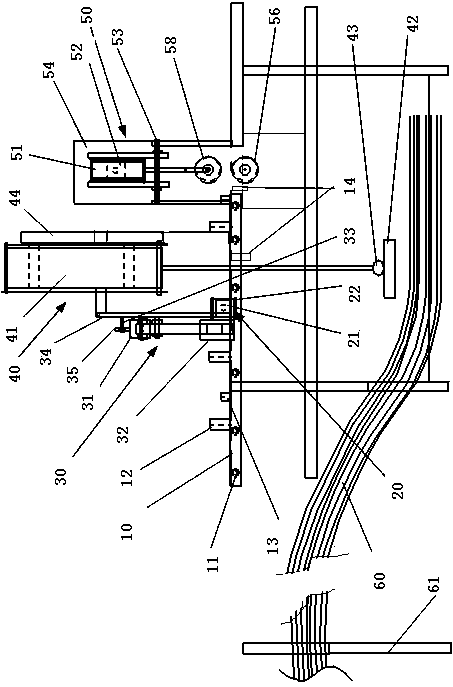

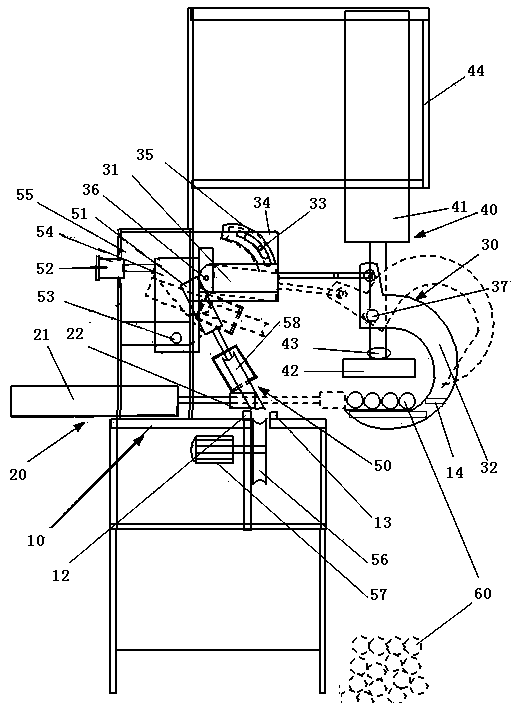

[0025] In the following orientations, the left-right direction in front of the reader is the X-axis direction, the front-back direction is the Y-axis direction, and the up-down direction is the Z-axis direction. The front of the steel bar length direction flowing along the X-axis direction is the direction of the next process or the front of the X-axis direction, the direction facing the reader is the rear of the Y-axis or the back of the equipment, and the direction close to the reader is the front.

[0026] The technical solution of the present invention will be described below in conjunction with the accompanying drawings. In order to illustrate the structure of the equipment more clearly, in the following description, the side of the translation device suction position is taken as the front, the front of the Y-axis direction or the front, and the translation device is translated. The side where the steel bars are placed is described as the rear, the rear or the back in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com