Automatic material throwing belt

An automatic feeding and conveyor belt technology, applied in the direction of conveyor control devices, conveyor objects, conveyors, etc., can solve problems such as difficult tension effects, complex feeding belt structure, etc., and achieve the effect of improving efficiency and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

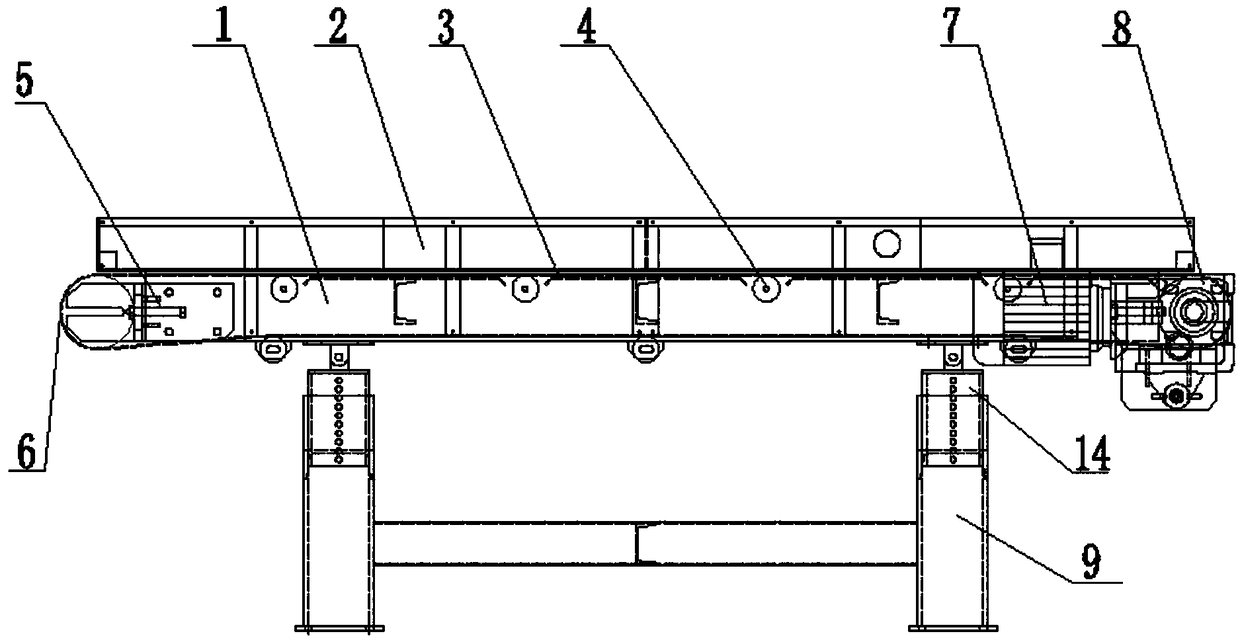

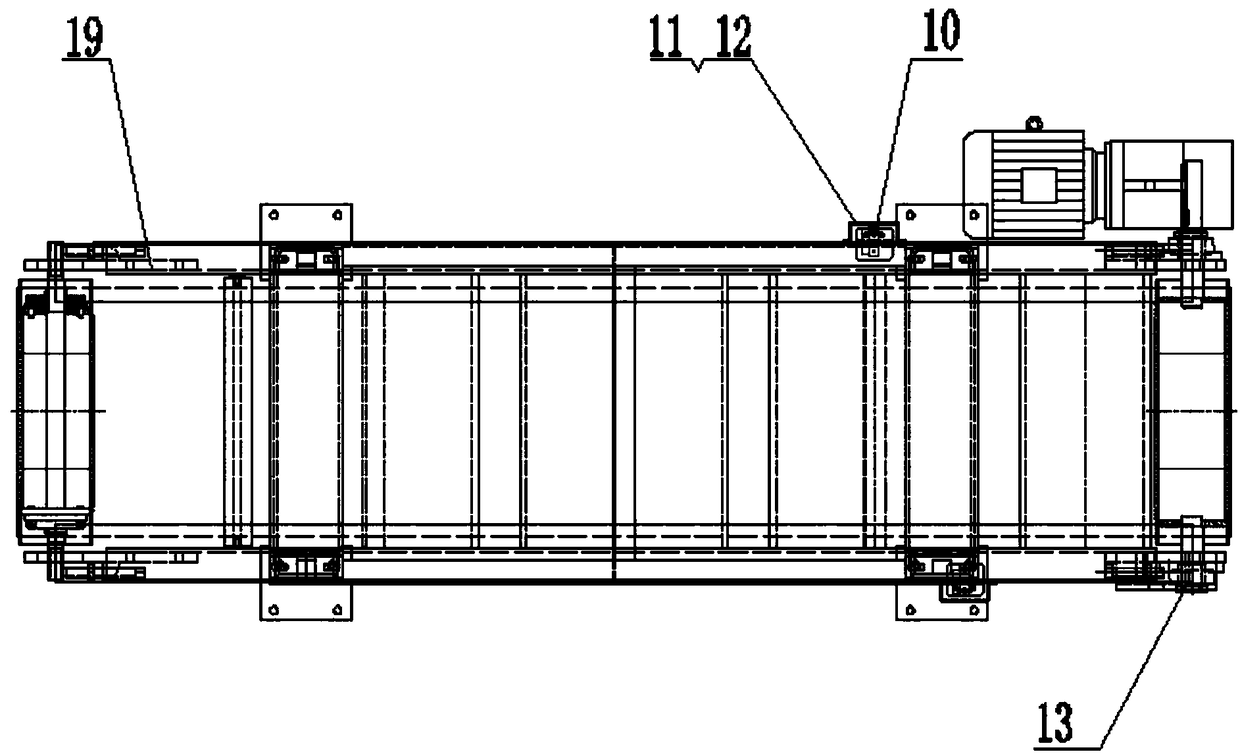

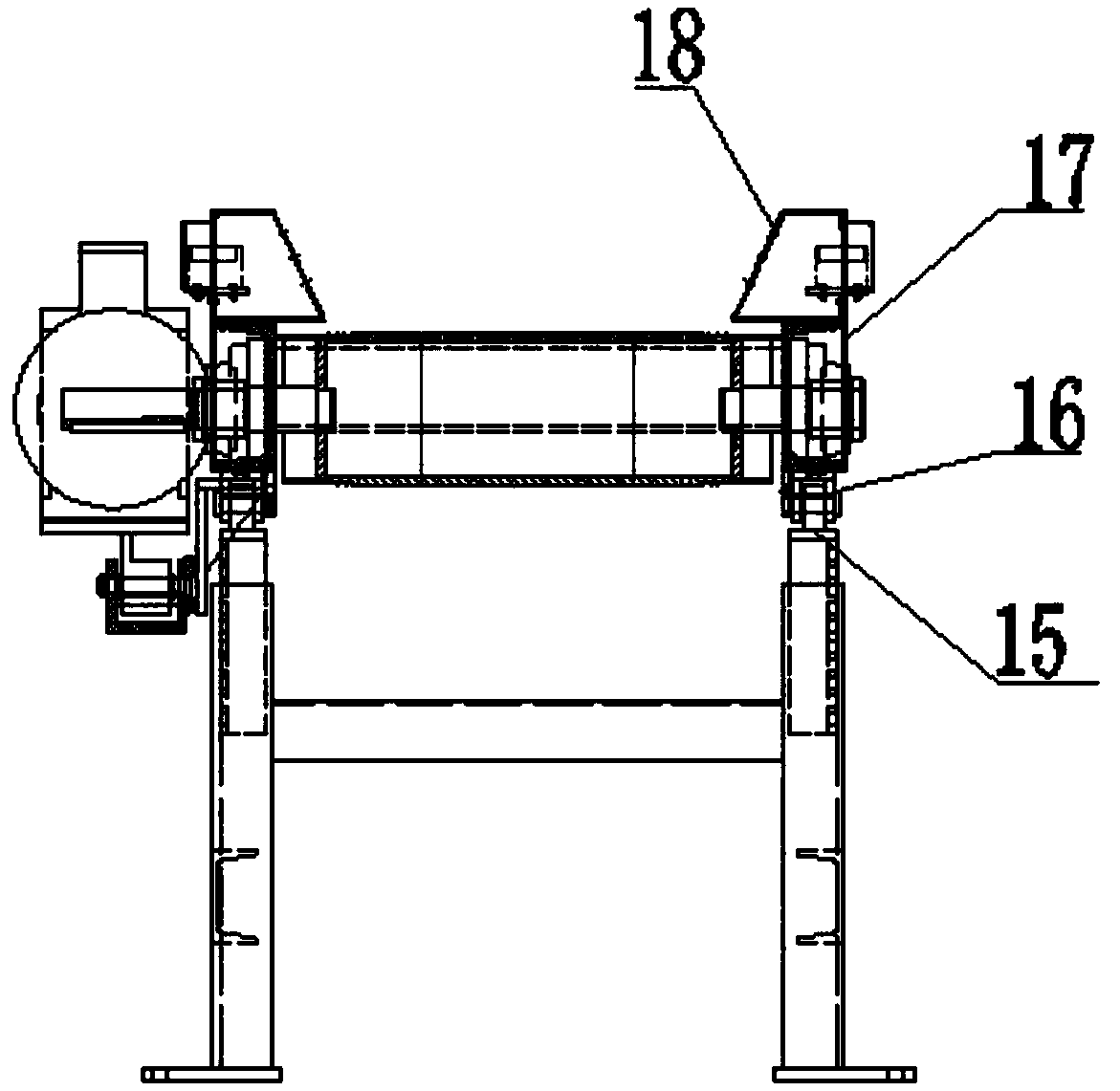

[0019] Such as Figure 1 to Figure 6 As shown, a kind of automatic feeding belt comprises frame 1, elevating bar 14, support leg 9, tail roller mounting plate 19, tail roller 6, tail roller shaft 55, conveyer belt 3 and tail roller tensioning device, the machine The frame is connected with the lifting rod, the lifting rod 14 is installed on the leg 9, the tail roller mounting plate 19 is installed at one end of the frame 1, and the tail roller tensioning device includes a tensioning motor 57 , gear 51, rack 52, spring 53, push block 54, rotating shaft 58, described tensioning motor 57 is fixed on the tail roller mounting plate 19, and the output end of described tensioning motor 57 is connected with rotating shaft 58, so Both ends of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com