Indenting and grooving integrated blade

A one-piece, slotting knife technology, applied in metal processing and other directions, can solve the problems of paper tube passing through, small application range, complex structure, etc., and achieve the effect of low manufacturing cost, good production effect and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

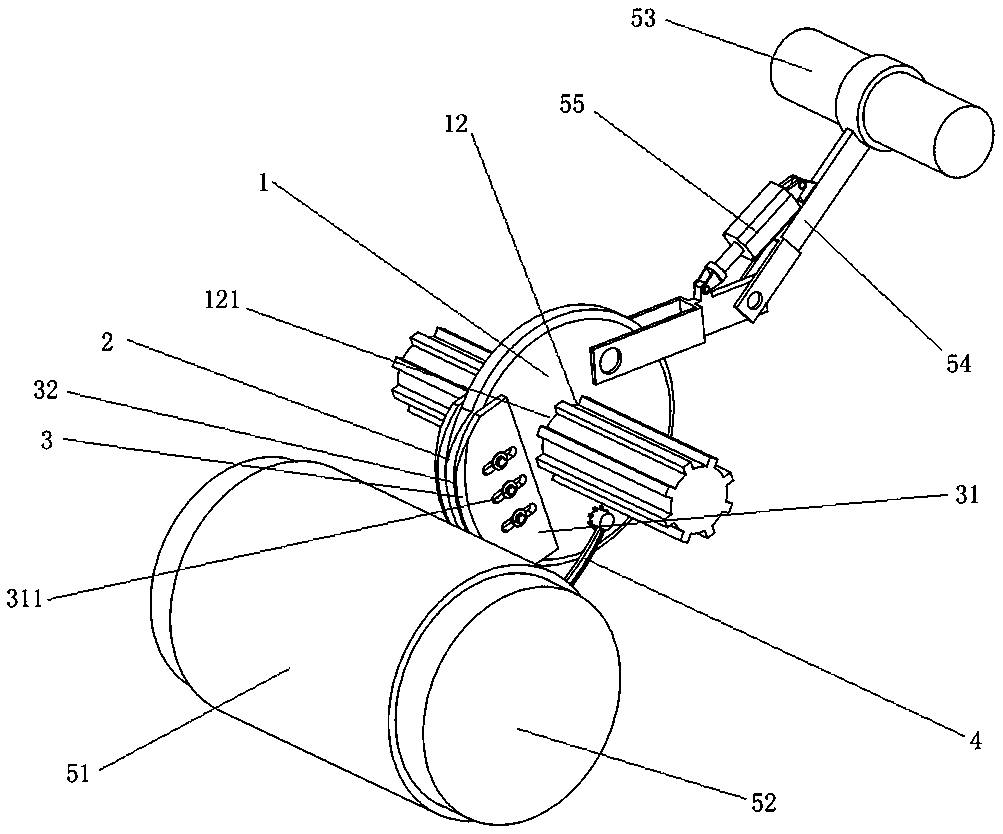

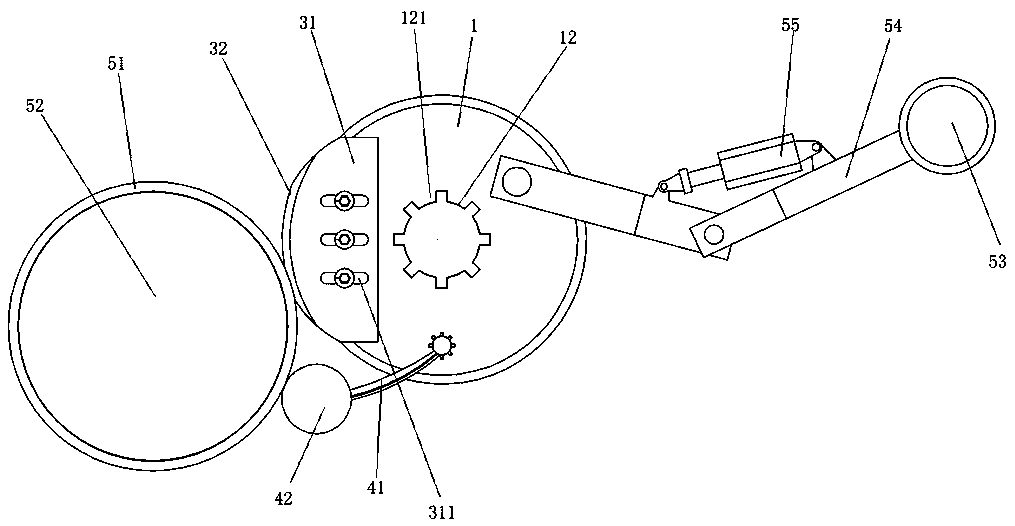

[0026] like figure 1 As shown, the creasing and grooving integrated blade described in the present invention is installed on a side cutting paper cutter (in other embodiments, this structure can be transferred to a special creasing and grooving machine), the paper cutter There is a rotating shaft 52 with a paper tube 51 on the outside, and a moving shaft 53 is arranged parallel to the side of the rotating shaft 52. A knife rest 54 is movably installed on the moving shaft 53. The shaft, the lower end of the shaft is hinged with a knife bar, and the front end of the knife bar is connected to the indentation slotting integrated blade of the present invention, and meanwhile, the two ends of the cylinder 55 are respectively hinged to the shaft and the knife bar.

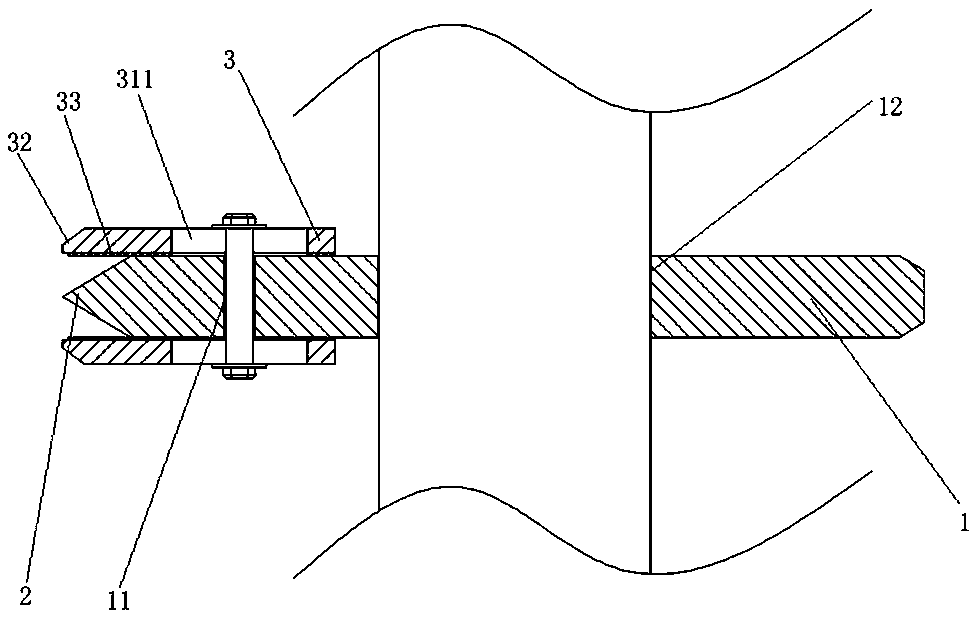

[0027] like figure 1 , 2 1. An indentation and slotting integrated blade shown in 3 includes a disc-shaped substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com