Plane and three-dimensional cascade remote experiment device

A remote experiment and three-dimensional technology, applied in the field of turbomachinery, can solve the problems of cumbersome and complicated manual operation, inaccurate measurement results, and limited measurement accuracy, and achieve the effect of shortening the experiment cycle, improving accuracy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

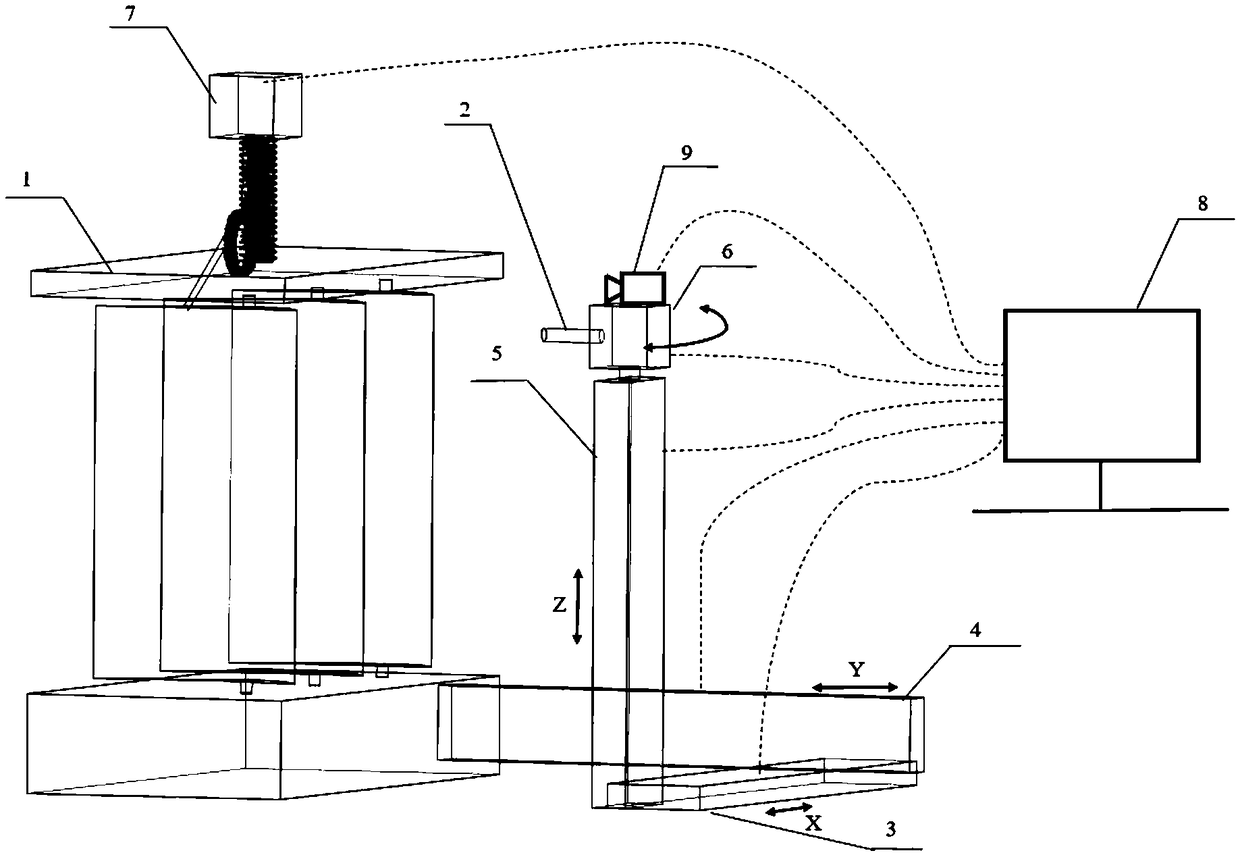

[0017] Referring to the accompanying drawings, the present invention provides a planar and three-dimensional cascade remote experimental device, including an X-direction linear motor 3, a Y-direction linear motor 4, and a Z-direction linear motor 5 that control the pressure probe 2 to move in the three directions of space XYZ. , the first stepper motor 6 that controls the rotation of the pressure probe 2, the second stepper motor 7 that controls the rotation of the blade cascade, the camera probe 9 that collects real-time images of the experimental device, and the position information, rotation angle and blade grid of the pressure probe 2 The rotation angle of the grid 1, the pressure signal measured by the pressure probe 2 is transmitted to several sensors of the remote control terminal 8, and the image signal of the experimental device collected by the camera probe 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com