Flameless pressure relief device

A pressure relief device, flameless technology, applied in valve device, fire rescue, safety valve, etc., can solve the problem that human-machine safety cannot be further guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

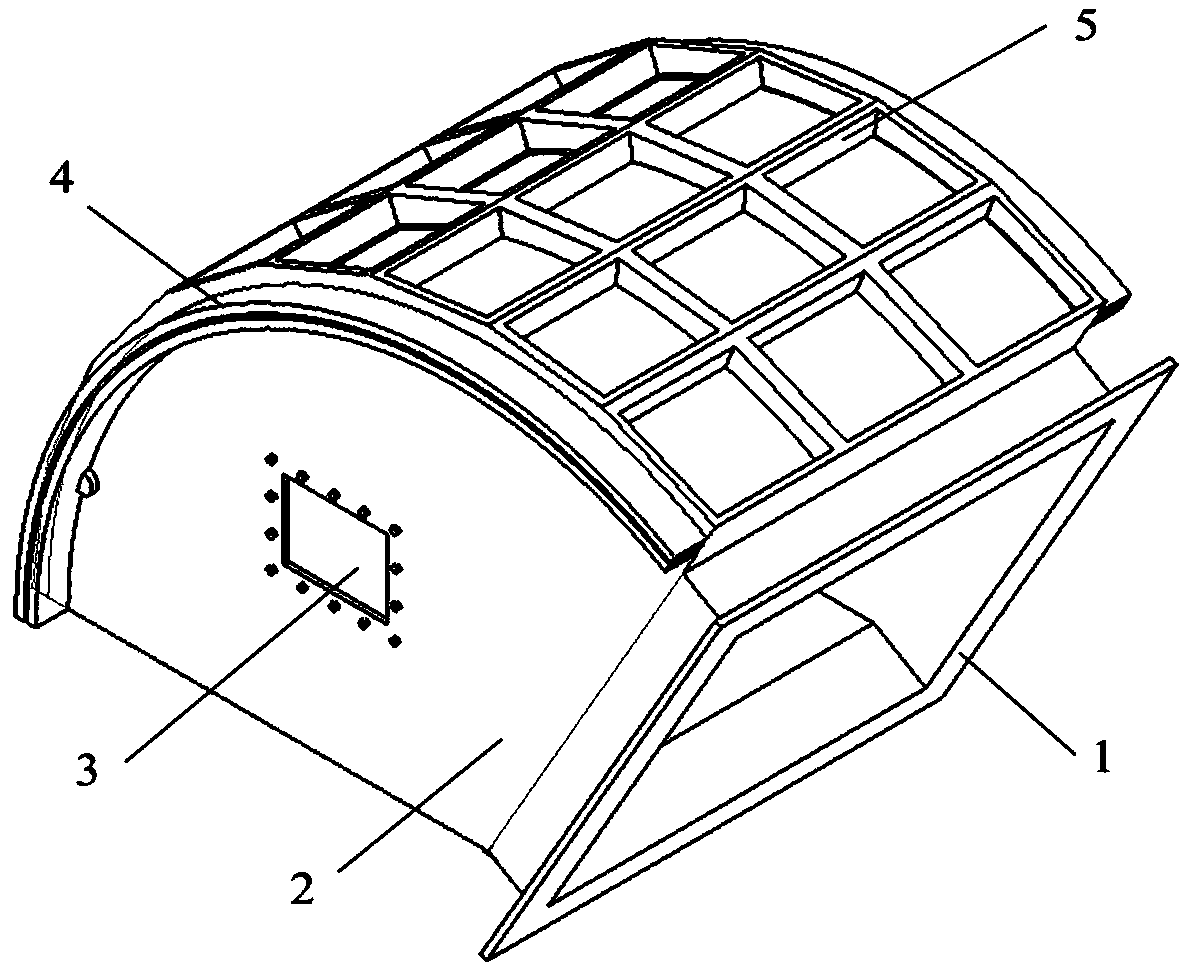

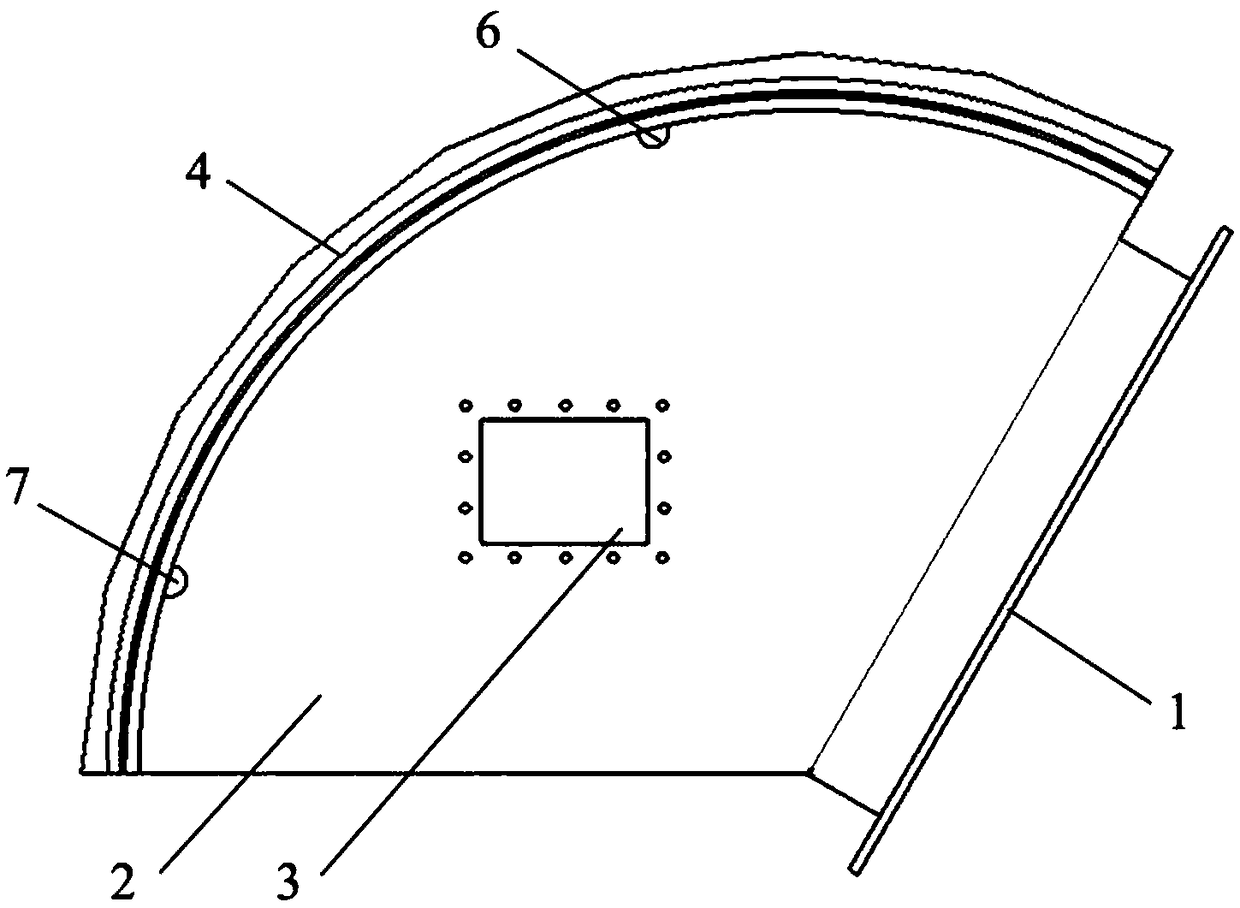

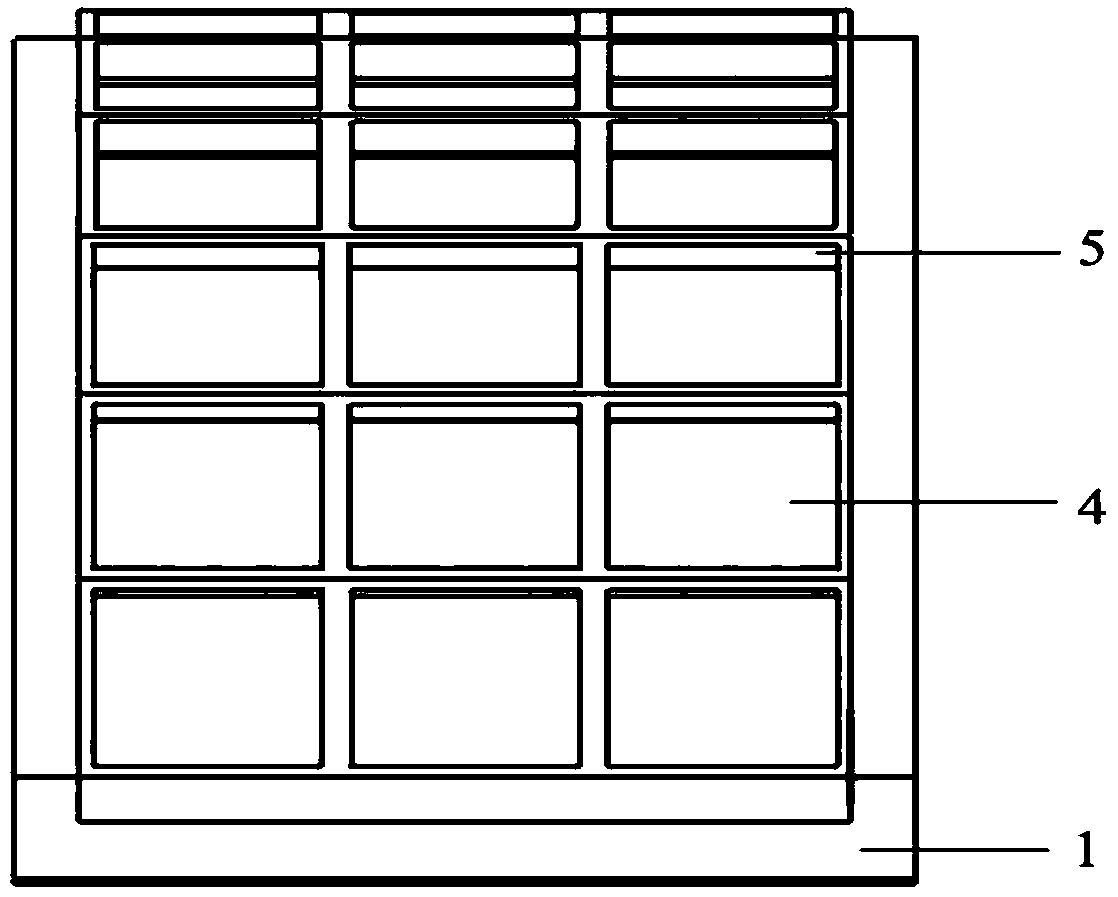

[0021] Such as figure 1 As shown, the shape of the pressure relief fire barrier layer of the flameless pressure relief device is a fan-shaped structure with a central angle greater than 90 degrees and less than 180 degrees, with a large pressure relief area and high pressure relief efficiency; the explosion vent plate 1 is installed at the entrance of the explosion vent shell 2 The inlet of the explosion venting shell 2 is connected to the pipeline; the fire retardant and pressure relief layer 4 is installed at the outlet of the explosion venting shell, and whether there is dust accumulation in the explosion venting shell can be observed through the window 3. When an explosion occurs, the explosion venting plate 1 ruptures under the action of the shock wave and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com