Production device and production method for soft, clean and pure yarn

A technology of production device and production method, which is applied in the field of spinning, and can solve problems such as inability to control fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

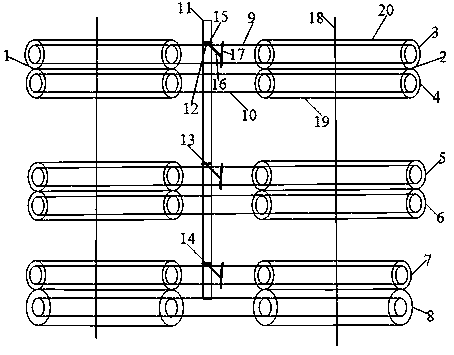

[0009] Depend on figure 1As shown, a soft and pure spinning production device includes front and rear car decks, the front and rear car decks have the same structure, and the front and rear car decks are composed of spindles , the number of spindle positions is between 200-600, each spindle position includes a drafting system, the drafting system includes a rear drafting roller pair consisting of rear bottom roller 4 and rear top rubber roller 3, middle bottom roller 6 and middle The middle drafting roller pair composed of top rubber roller 5, the front drafting roller pair composed of front bottom roller 8 and front top rubber roller 7, the structures of rear roller, middle roller and front roller are exactly the same, and the rear roller, middle roller, The front roller includes a roller shaft 10, which is made of iron or steel with a solid cylindrical structure. The roller sleeves 19 are sleeved on the roller shafts on each spindle position. The roller sleeves are made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com