Cooking cleaning device for extraction of bamboo fibers

A technology for cleaning equipment and bamboo fibers, applied in the chemical post-processing of fibers, fiber processing, textiles and papermaking, etc., can solve problems such as low production efficiency, and achieve the effect of convenient loading and unloading, cleaning and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

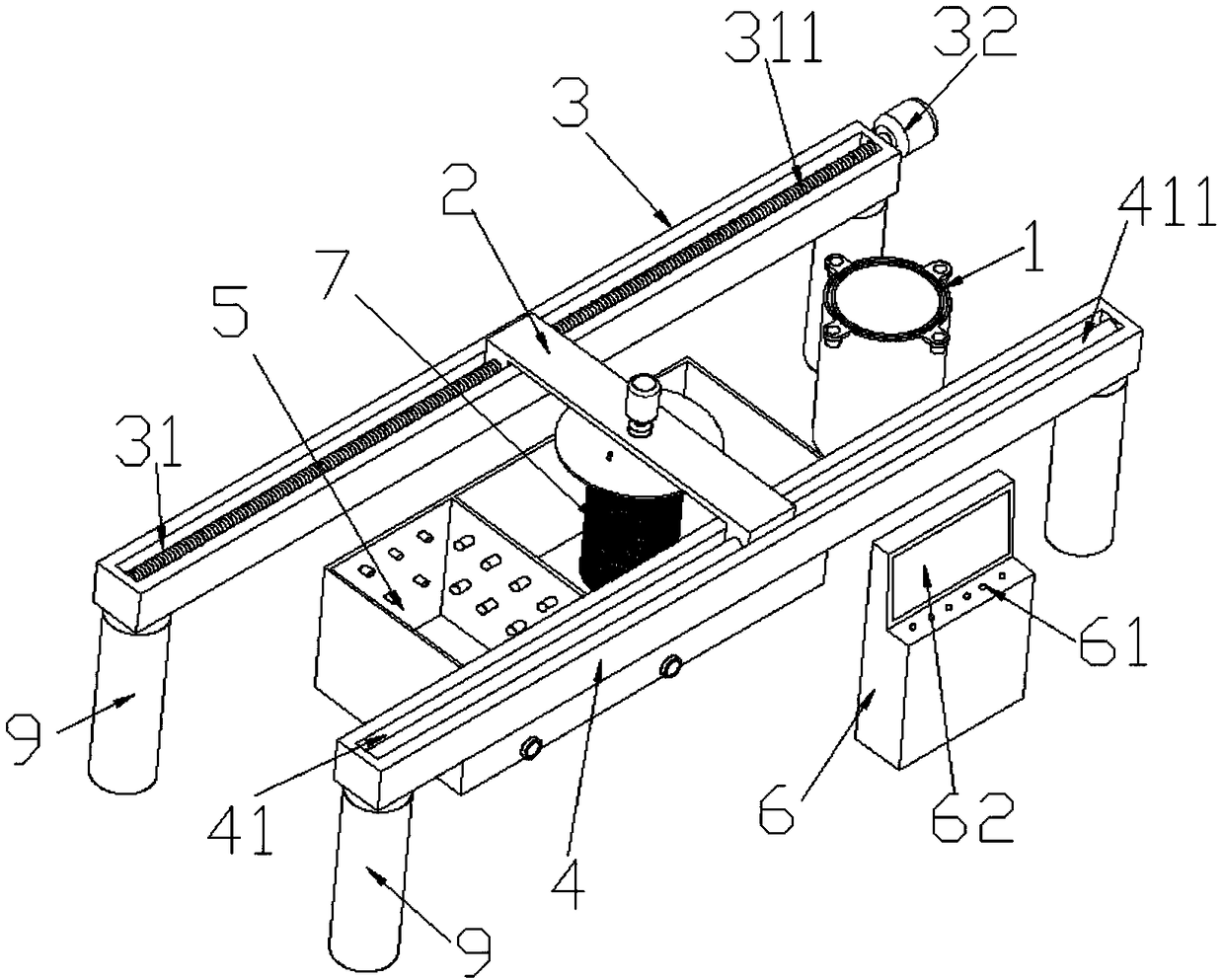

[0035] Such as Figure 1 to Figure 8 As shown, a cooking and cleaning equipment for extracting bamboo fiber is characterized in that it includes a cooking barrel 1, a sliding cover assembly 2, a left slide rail 3, a right slide rail 4, a cleaning box 5, a control cabinet 6, and a placement frame 7 ;

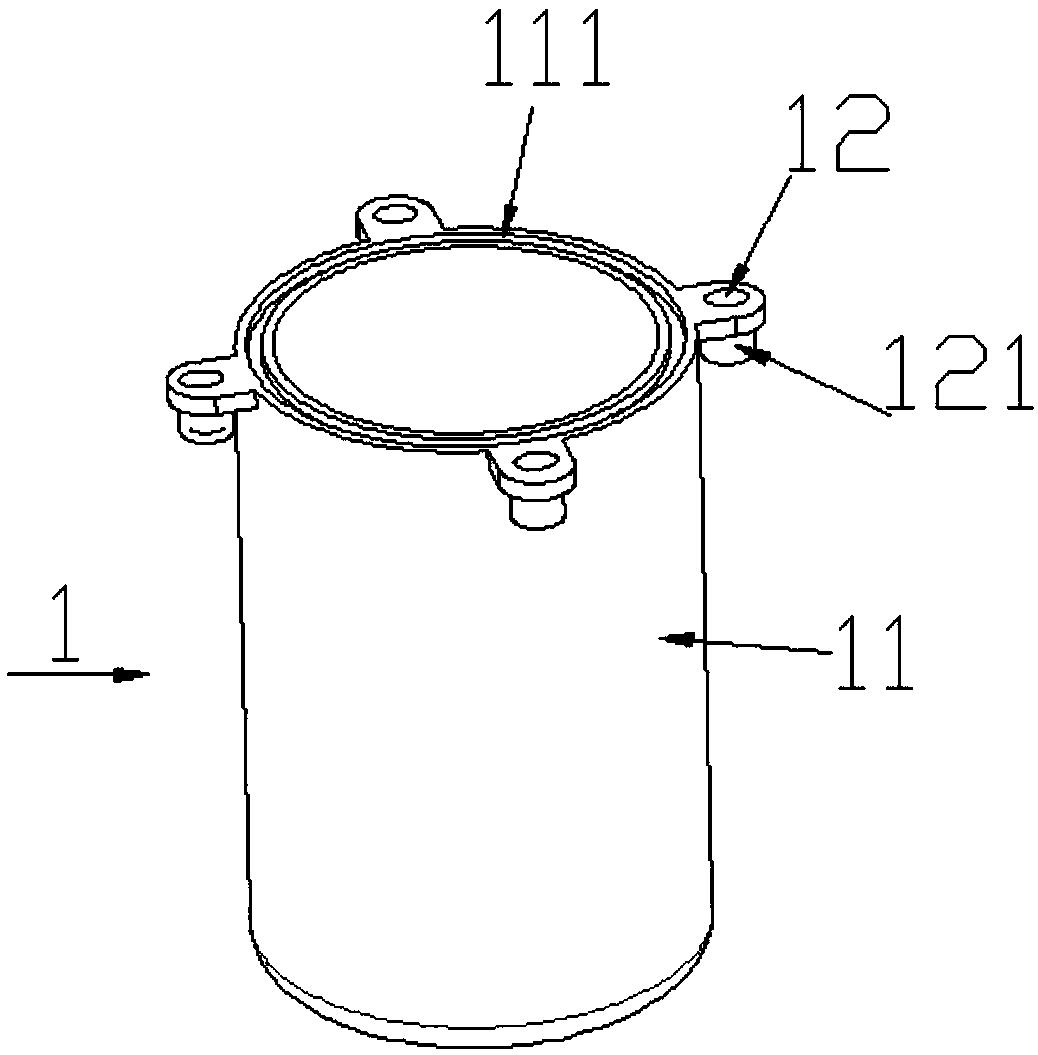

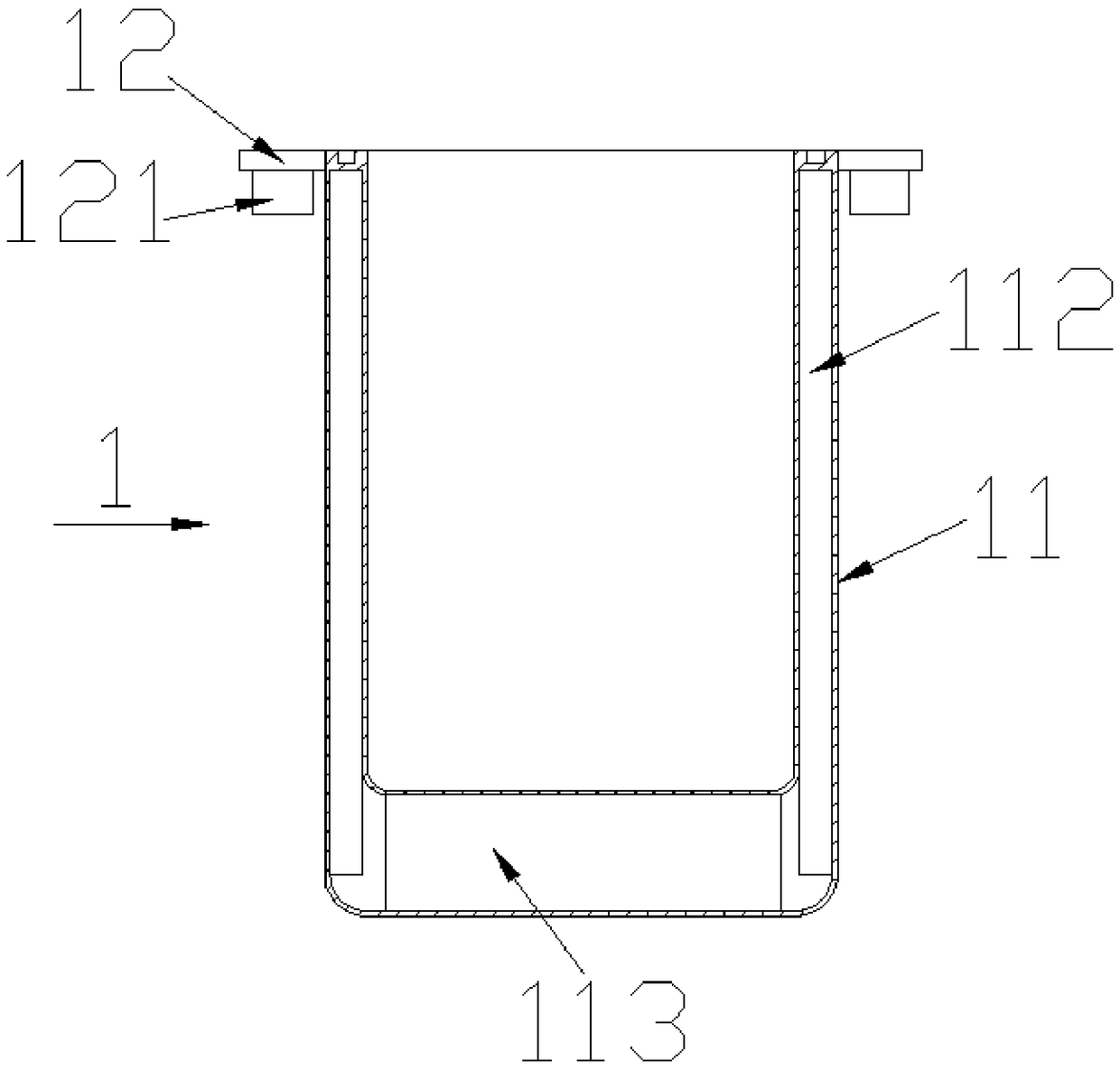

[0036] The cooking barrel 1 includes a barrel body 11, and an ear plate 12 is arranged on the outside of the top of the barrel body 11, and an electromagnet 121 is fixed on the ear plate 12, and the electromagnet 121 is electrically connected to the control cabinet 6; The bottom of the barrel body 11 is provided with an electromagnetic heating device 113, and the electromagnetic heating device 113 is electrically connected to the control cabinet 6, and a vacuum insulation chamber 112 is provided in the side wall of the barrel body 11; There is an annular sealing groove 111; the section of the annular sealing groove 111 is rectangular;

[0037] The sliding lid assembly 2 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com