White stain-bleeding printing ink for ceramic ink-jet printing and preparation method thereof

A ceramic inkjet, white technology, applied in the field of white bleed ink and its preparation, can solve problems such as narrow color gamut, and achieve the effect of rich color gamut and good inkjet printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of isooctanoic acid metal salt comprises the following steps:

[0026] (1) Using NaOH and isooctanoic acid as raw materials, the temperature is controlled at 80°C, and sodium isooctanoate is prepared through acid-base saponification;

[0027] (2) The sodium isooctanoic acid salt in step (1) is configured into a solution with a mass fraction of 20%, adding 20% water-soluble metal salt solution and an appropriate amount of alkane solvent and mixing; the temperature is raised to 90° C., and reacted for 2 hours;

[0028] (3) After the reaction is completed, the liquid is extracted and separated, and the residual moisture is removed by distillation at a temperature of 120° C. to obtain the chromogenic organic isooctanoic acid metal salt;

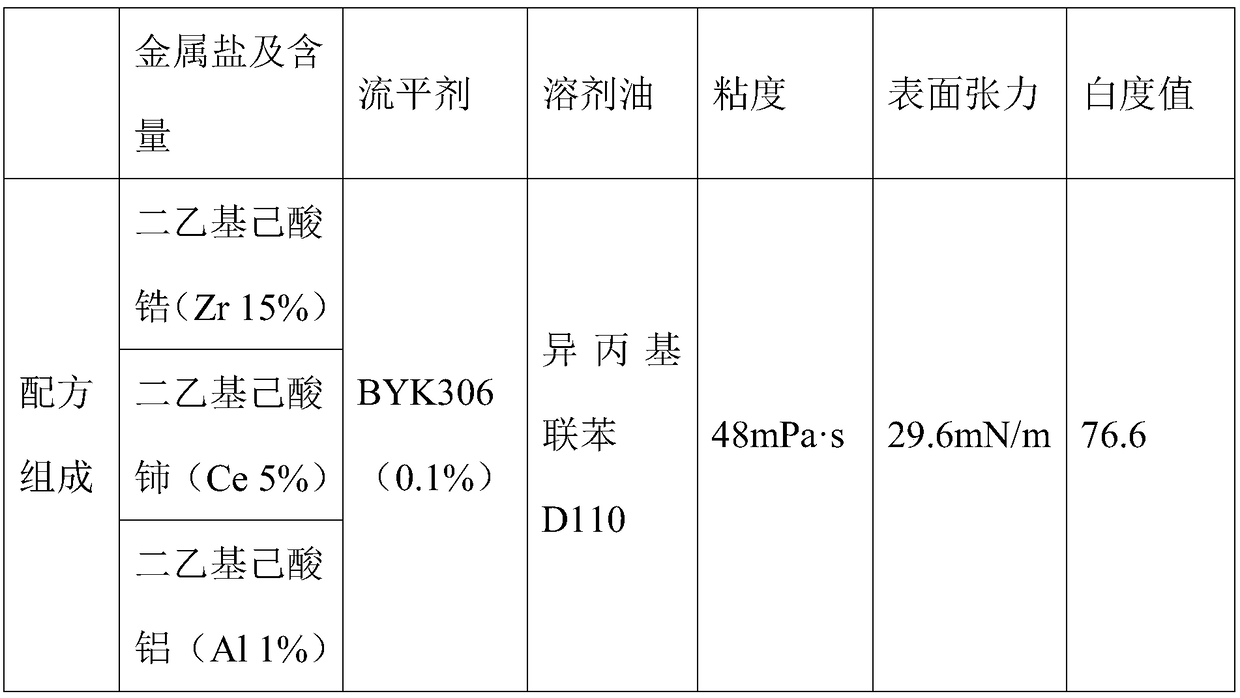

[0029] Mix the leveling agent, the color-forming organic metal salt and the solvent according to the ratio in the table, stir evenly, and filter with a 1 micron filter element to obtain the white bleeding ink for c...

Embodiment 2

[0032] The preparation method of isooctanoic acid metal salt is with embodiment 1.

[0033] Mix the leveling agent, the color-forming organic metal salt and the solvent according to the ratio in the table, stir evenly, and filter with a 1 micron filter element to obtain the white bleeding ink for ceramic inkjet printing.

[0034]

Embodiment 3

[0036] The preparation method of naphthenic acid metal salt comprises the following steps:

[0037] (1) Using NaOH and naphthenic acid as raw materials, the temperature is controlled at 100 ° C, and sodium isooctanoate is prepared by acid-base saponification;

[0038] (2) The sodium salt of isooctanoic acid in step (1) is configured into a solution with a mass fraction of 40%, adding 10% water-soluble metal salt solution and an appropriate amount of esters and mixing; the temperature is raised to 120° C., and reacted for 2 hours;

[0039] (3) After the reaction is completed, the liquid is extracted and separated, and the residual moisture is removed by distillation at a temperature of 100° C. to obtain the chromogenic organic isooctanoic acid metal salt;

[0040] Mix the leveling agent, the color-forming organic metal salt and the solvent according to the ratio in the table, stir evenly, and filter with a 1 micron filter element to obtain the white bleeding ink for ceramic ink...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com