Copper sulfide/bismuth vanadate heterojunction photocatalyst and preparation method thereof

A photocatalyst, bismuth vanadate technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of narrow visible light absorption range, practical application limitations, impact Solve problems such as copper sulfide formation, achieve strong pollutant degradation ability, wide visible light absorption range, and improve photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

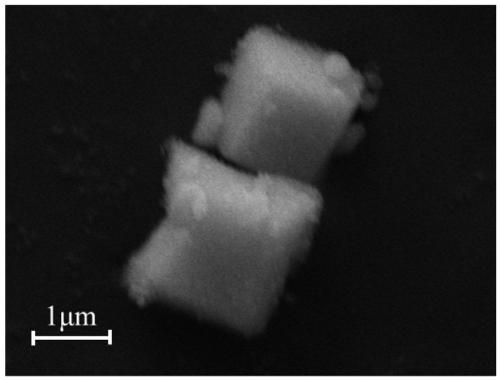

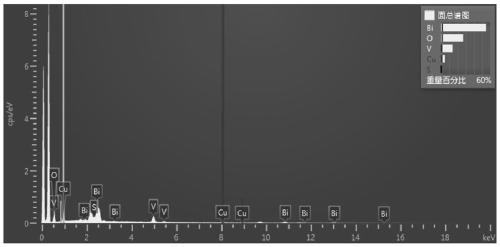

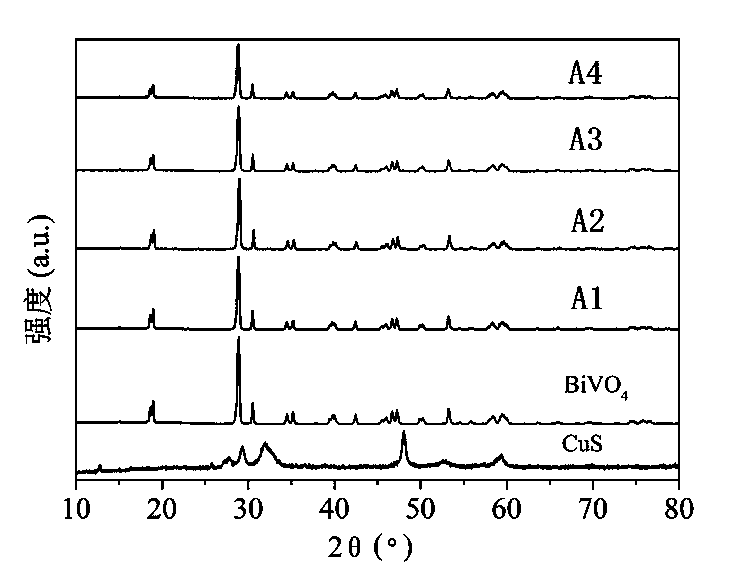

[0039] A copper sulfide / bismuth vanadate heterojunction photocatalyst comprises bismuth vanadate and copper sulfide, and the copper sulfide is attached to the bismuth vanadate to form a heterojunction material.

[0040] In this embodiment, the mass ratio of copper sulfide to bismuth vanadate in the copper sulfide / bismuth vanadate heterojunction photocatalyst is 3:97.

[0041] In this embodiment, the bismuth vanadate is in a block shape with a thickness of 1 μm to 2 μm; the copper sulfide is in a granular shape.

[0042] A method for preparing the copper sulfide / bismuth vanadate heterojunction photocatalyst of the above-mentioned present embodiment, comprising the following steps:

[0043] (1) Dissolve 6 mmol of bismuth nitrate pentahydrate in 32 mL of nitric acid solution with a concentration of 1 mol / L, and sonicate for 10 min to obtain a bismuth nitrate solution; add 6 mmol of ammonium metavanadate to the above bismuth nitrate solution, and magnetically Stir for one hour to...

Embodiment 2

[0046] A copper sulfide / bismuth vanadate heterojunction photocatalyst, which is basically the same as the copper sulfide / bismuth vanadate heterojunction photocatalyst in Example 1, the only difference being: the copper sulfide / bismuth vanadate heterojunction in Example 2 The mass ratio of copper sulfide to bismuth vanadate in the photocatalyst is 1:19.

[0047] A preparation method of the copper sulfide / bismuth vanadate heterojunction photocatalyst of the above-mentioned present embodiment is basically the same as the preparation method of the copper sulfide / bismuth vanadate heterojunction photocatalyst in Example 1, the only difference being: Example 2 The dosages of copper nitrate trihydrate and sodium thiosulfate pentahydrate in step (2) of the preparation method are 0.0397g and 0.0408g respectively.

[0048] Preparation copper sulfide / bismuth vanadate heterojunction photocatalyst (CuS / BiVO 4 ), numbered A2.

Embodiment 3

[0050] A copper sulfide / bismuth vanadate heterojunction photocatalyst, which is basically the same as the copper sulfide / bismuth vanadate heterojunction photocatalyst in Example 1, the only difference being: the copper sulfide / bismuth vanadate heterojunction in Example 3 The mass ratio of copper sulfide to bismuth vanadate in the photocatalyst is 7:93.

[0051] A preparation method of the copper sulfide / bismuth vanadate heterojunction photocatalyst of the above-mentioned present embodiment is basically the same as the preparation method of the copper sulfide / bismuth vanadate heterojunction photocatalyst in Example 1, the only difference being: Example 3 The dosages of copper nitrate trihydrate and sodium thiosulfate pentahydrate in step (2) of the preparation method are 0.0568 g and 0.083 g, respectively.

[0052] Preparation copper sulfide / bismuth vanadate heterojunction photocatalyst (CuS / BiVO 4 ), numbered A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com