Multi-point acoustic guitar side plate shape-forming support device

A support device and multi-point technology, which is applied to guitars, musical instruments, stringed instruments, etc., can solve the problems of no professional equipment on the side panels, increase the number of brackets, and affect the shaping effect, so as to improve the shaping effect, reduce investment, and improve Styling effect and stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0020] Embodiments of the invention:

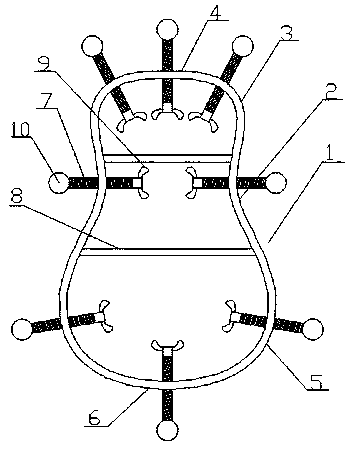

[0021] A multi-point acoustic guitar side panel shaping support device, as attached Figure 1-2 As shown, a gourd-shaped support frame body 1 is included, and the perimeter of the support frame body 1 is less than the perimeter of the side plate of the acoustic guitar (the distance between the inner wall of the side plate and the outer wall of the support frame body 1 can be about 5 cm. ), the middle part of the support frame body 1 is the waist support section 2, the upper part of the waist support section 2 is the upper shoulder support section 3 and the top support section 4, and the lower part of the waist support section 2 is the lower shoulder support section 5 and the bottom support section Segment 6, lumbar support segment 2, upper shoulder support seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com