Intelligent manufacturing plant virtual debugging and virtual monitoring method and system based on digital twinning

An intelligent manufacturing and twinning technology, which is applied in the direction of comprehensive factory control, comprehensive factory control, control/regulation system, etc., can solve the problems of data connection interruption, digital model and physical equipment separation, etc., to avoid unplanned downtime and realize prediction The effect of sexual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

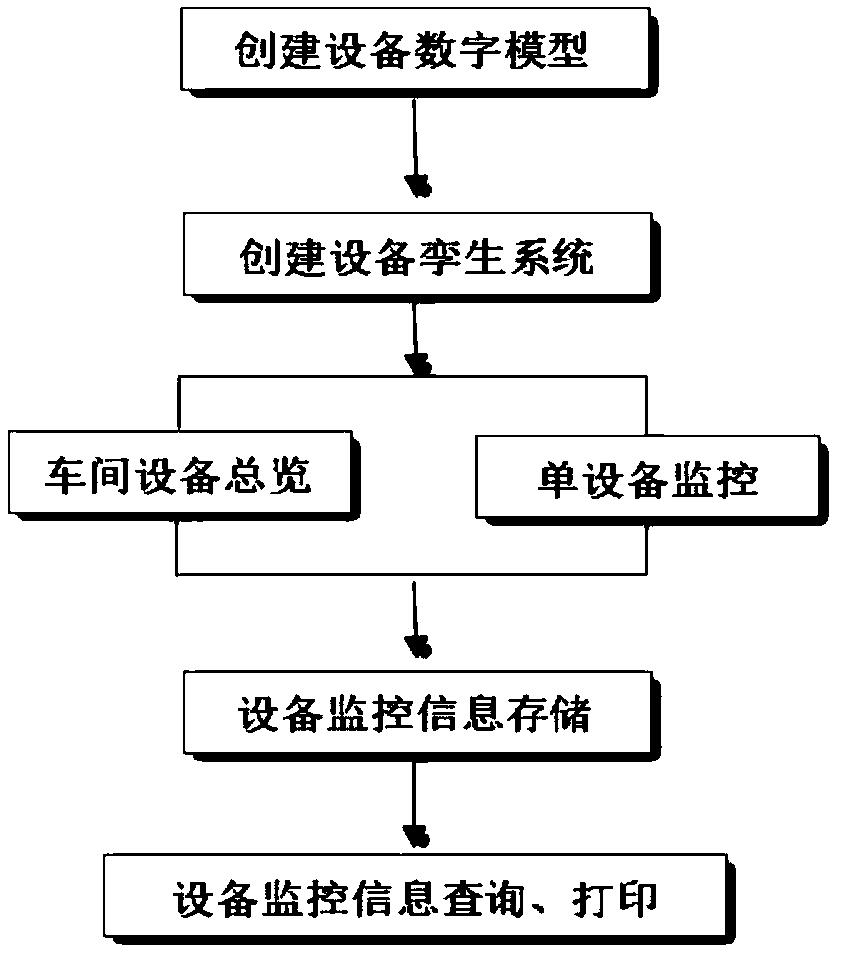

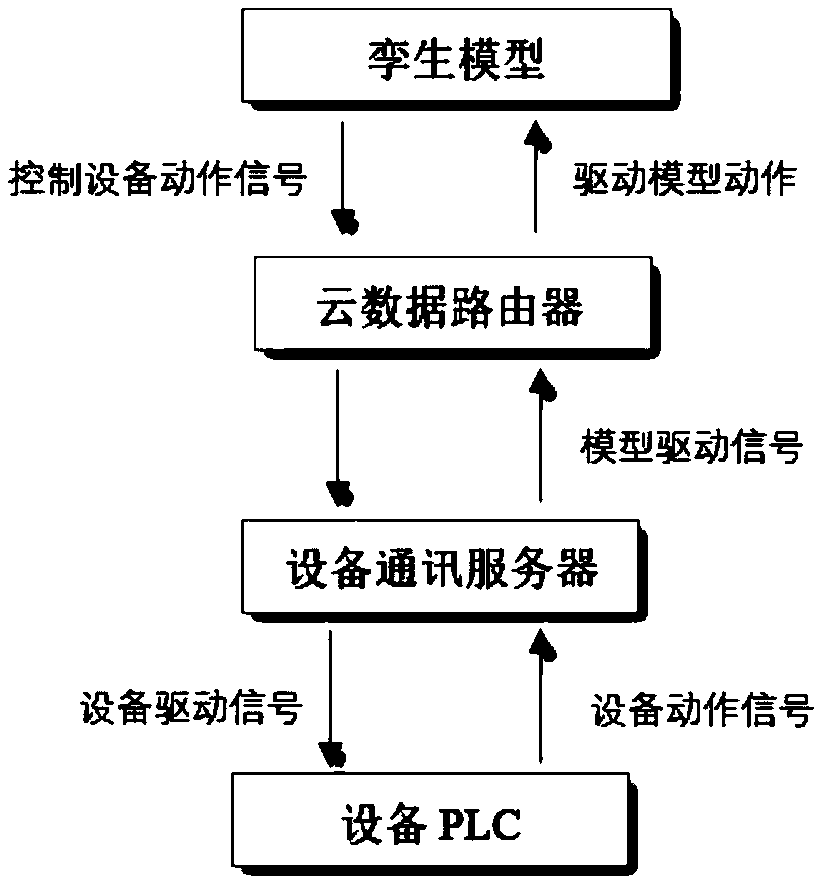

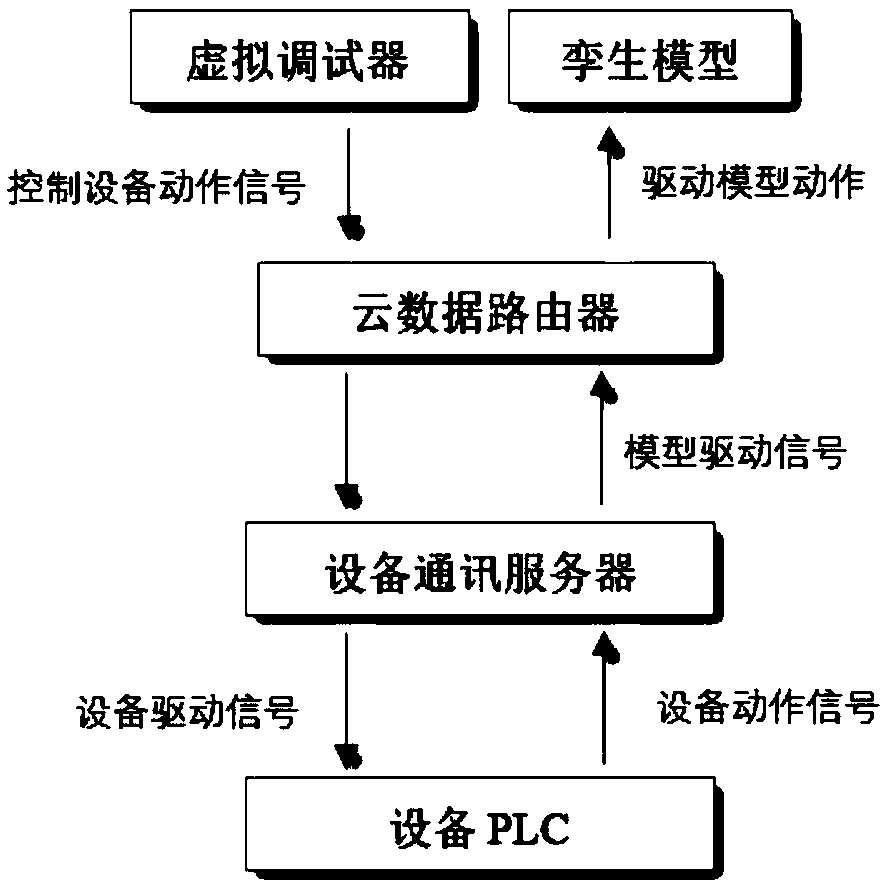

[0034] Such as Figure 1-Figure 3 A digital twin-based virtual commissioning and virtual monitoring method for an intelligent manufacturing factory is shown, which specifically includes the following steps:

[0035] S1: Establish 3D models of various physical equipment in the factory workshop in 3D modeling software such as CAD or Solidworks

[0036] S2: Import the 3D model into the digital twin system and optimize the 3D model. At the same time, input the design parameter information and production process parameter information of the physical equipment into the twin system to confirm the operations of the physical equipment and the requirements for each task. Time, a twin digital model co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com