High refractive index polarization splitting prism

A polarizing beam splitting prism, high refractive index technology, applied in polarizing elements, optics, optical elements, etc., can solve problems such as miniaturization design limitations, and achieve the effect of reducing the incidence angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

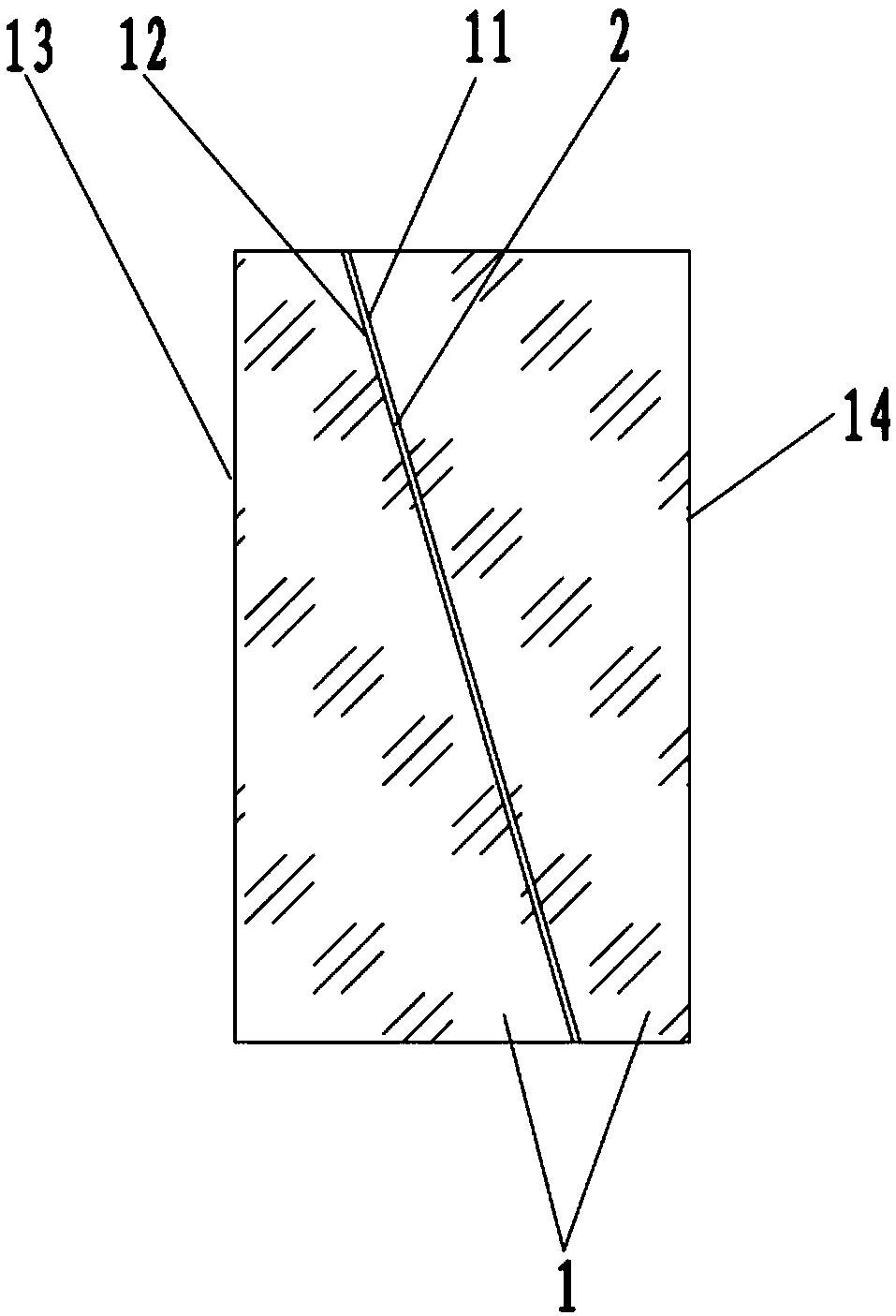

[0027] Such as figure 1 As shown, the high refractive index polarization beam splitter prism of the present invention comprises a pair of right-angle prisms 1, the slopes of the pair of right-angle prisms 1 are fixed to each other and one of the slopes is coated with a polarization beam-splitting film 2, and the pair of right-angle prisms 1 Molded for high emissivity materials.

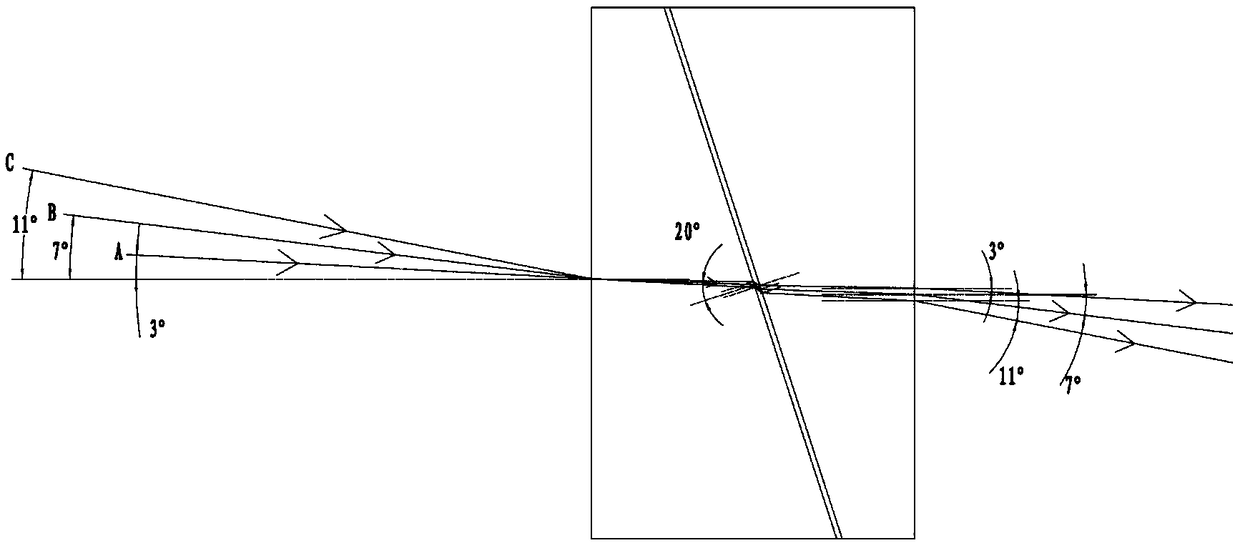

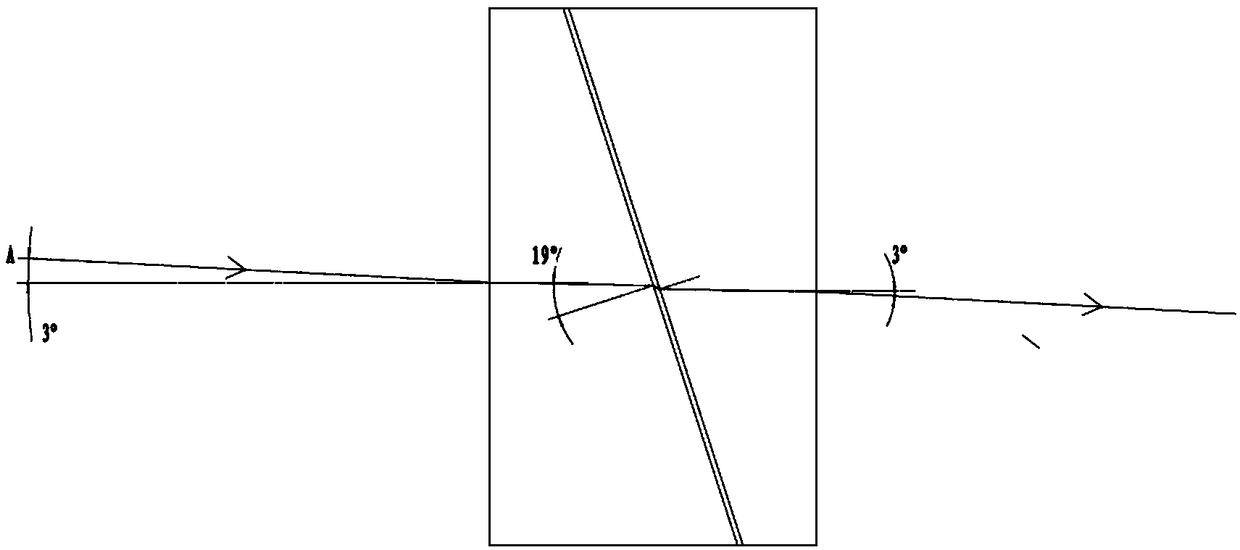

[0028] As a preferred solution, the high-refractive-index material can be single-crystal silicon. Since the refractive index of single-crystal silicon is as high as about 3.42 at room temperature, single-crystal silicon is used for molding figure 1 After the right-angle prism with the structure shown, the polarization beam-splitting film of the polarization beam-splitting prism formed by it forms two beams of linearly polarized light with an incident angle ranging from 8° to 25°. In addition, see figure 2 , the incident angle range of the light incident from the air to the rectangular prism is 7°±4°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com