Test device and test method for outgassing during pyrolysis of ablation-resistant phenolic resin

A technology of phenolic resin and testing equipment, which is applied in the direction of analysis materials and instruments, etc., can solve the problems that the accurate measurement of the pyrolysis gas volume of ablation-resistant phenolic resin cannot be realized, and the composition is complicated, so as to achieve high integration and automatic control, reduce Labor cost, the effect of reducing the workload of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

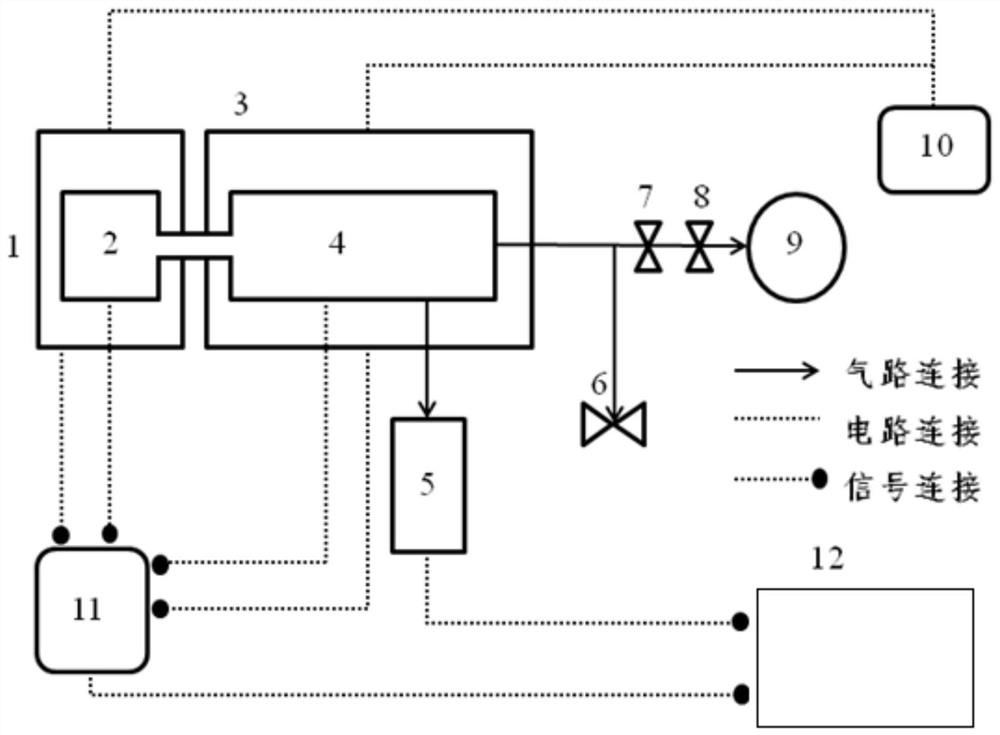

[0069] see figure 1 , this embodiment provides a test device for outgassing in the pyrolysis process of phenolic resin, including a sample chamber 2, a gas diffusion chamber 4, a heating system, a vacuum control system, a temperature control and measurement device, a high temperature vacuum pressure gauge (pressure measurement device 5) and data acquisition and processing system 12;

[0070] The gas diffusion chamber 4 and the sample chamber 2 are both of chrome-aluminum alloy material cuboid structure, and the inner wall of the chamber is smooth to ensure the maximum reduction of the surface area of the inner wall of the chamber. The gas diffusion chamber 4 and the sample chamber 2 have a suitable connecting knife edge , The knife-edge connection position is sealed by a copper gasket, and the structure is removable and washable, which is convenient for the device to be reused;

[0071] The heating system includes a sample chamber heating jacket (sample chamber heating asse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com