Loading device for static strength test of end wall of car body

A loading device and static strength technology, applied in the direction of measuring devices, strength characteristics, railway vehicle testing, etc., can solve the problems that the static strength test of the end wall of the car body cannot be implemented and cannot be loaded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

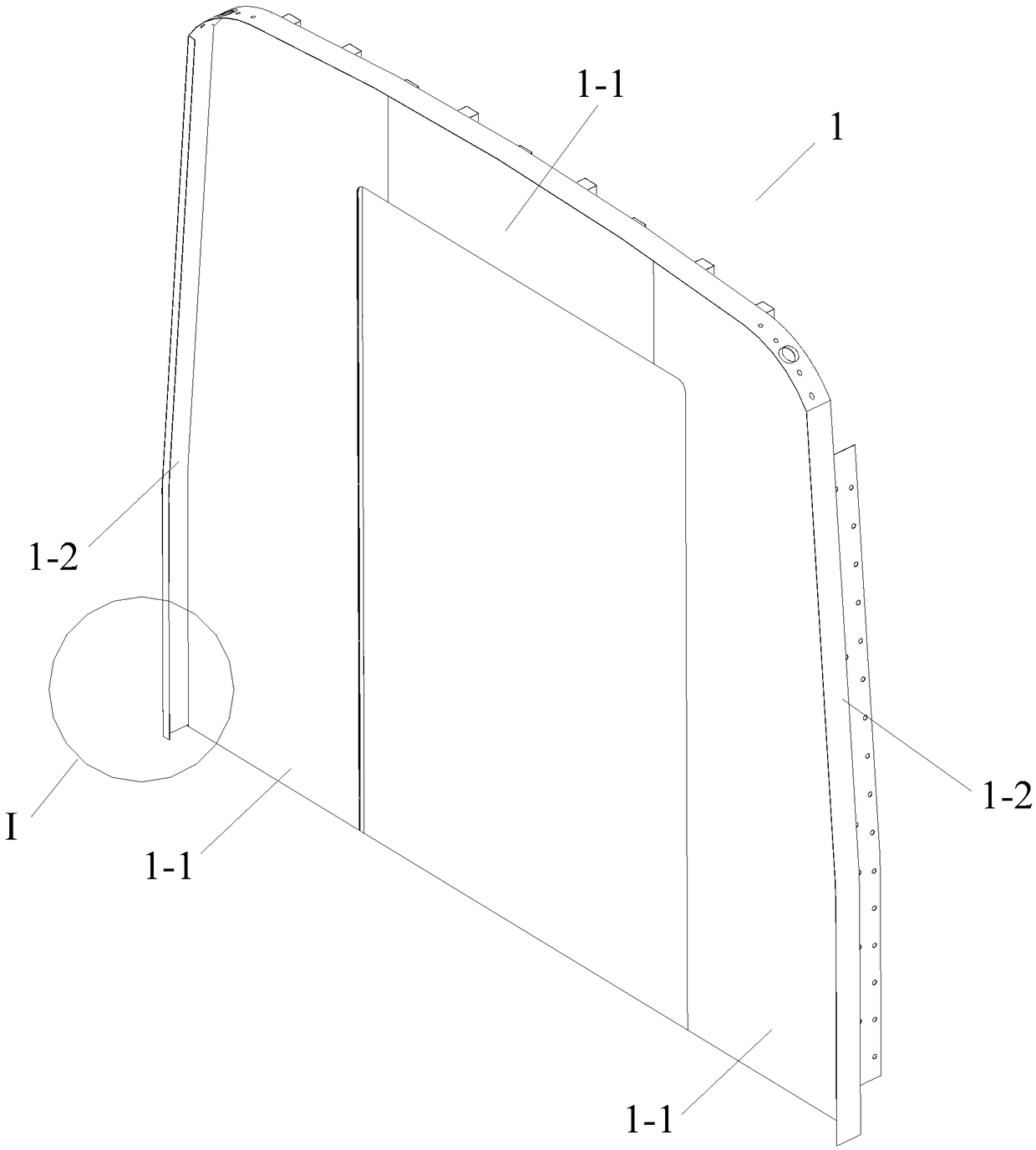

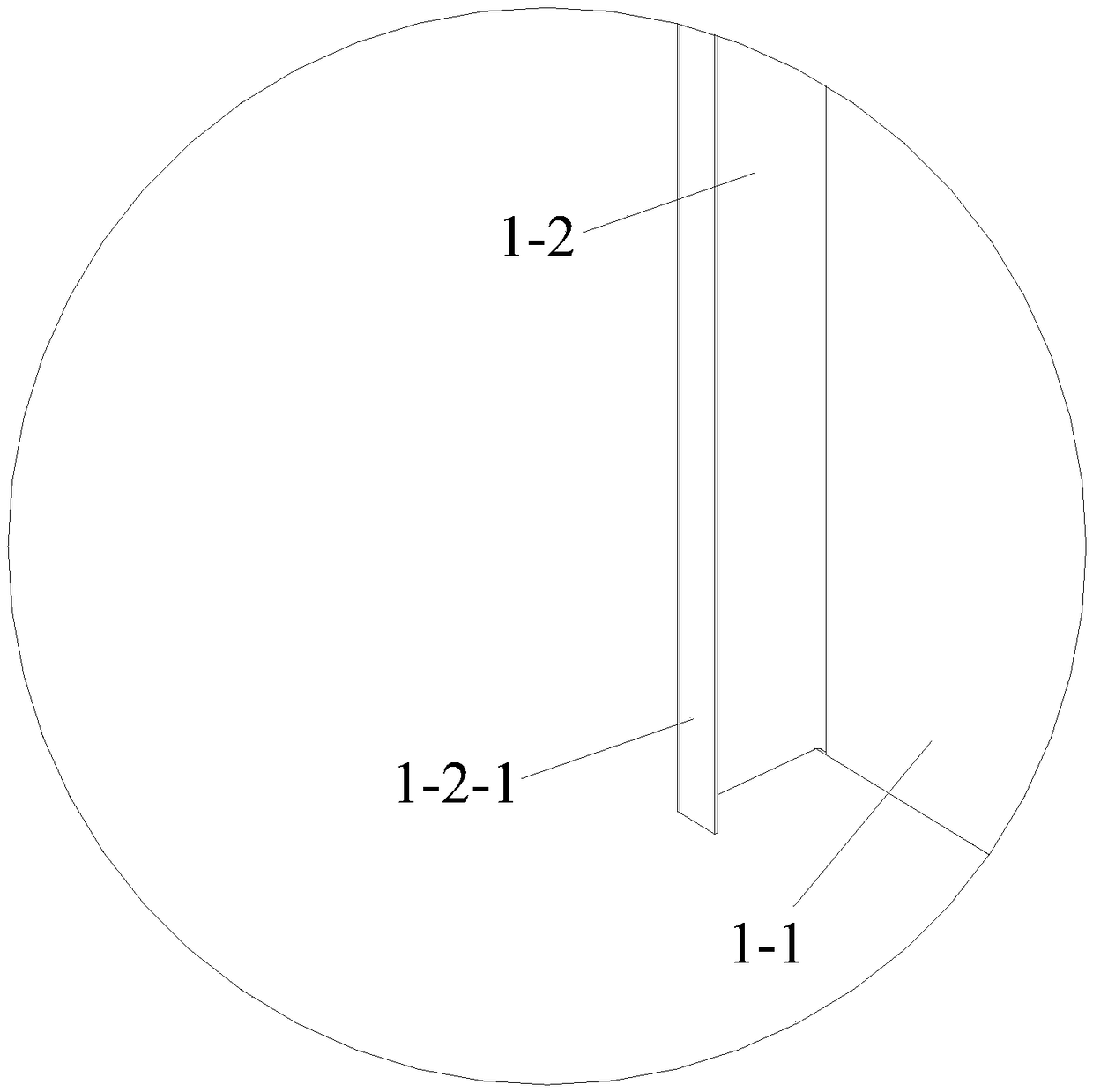

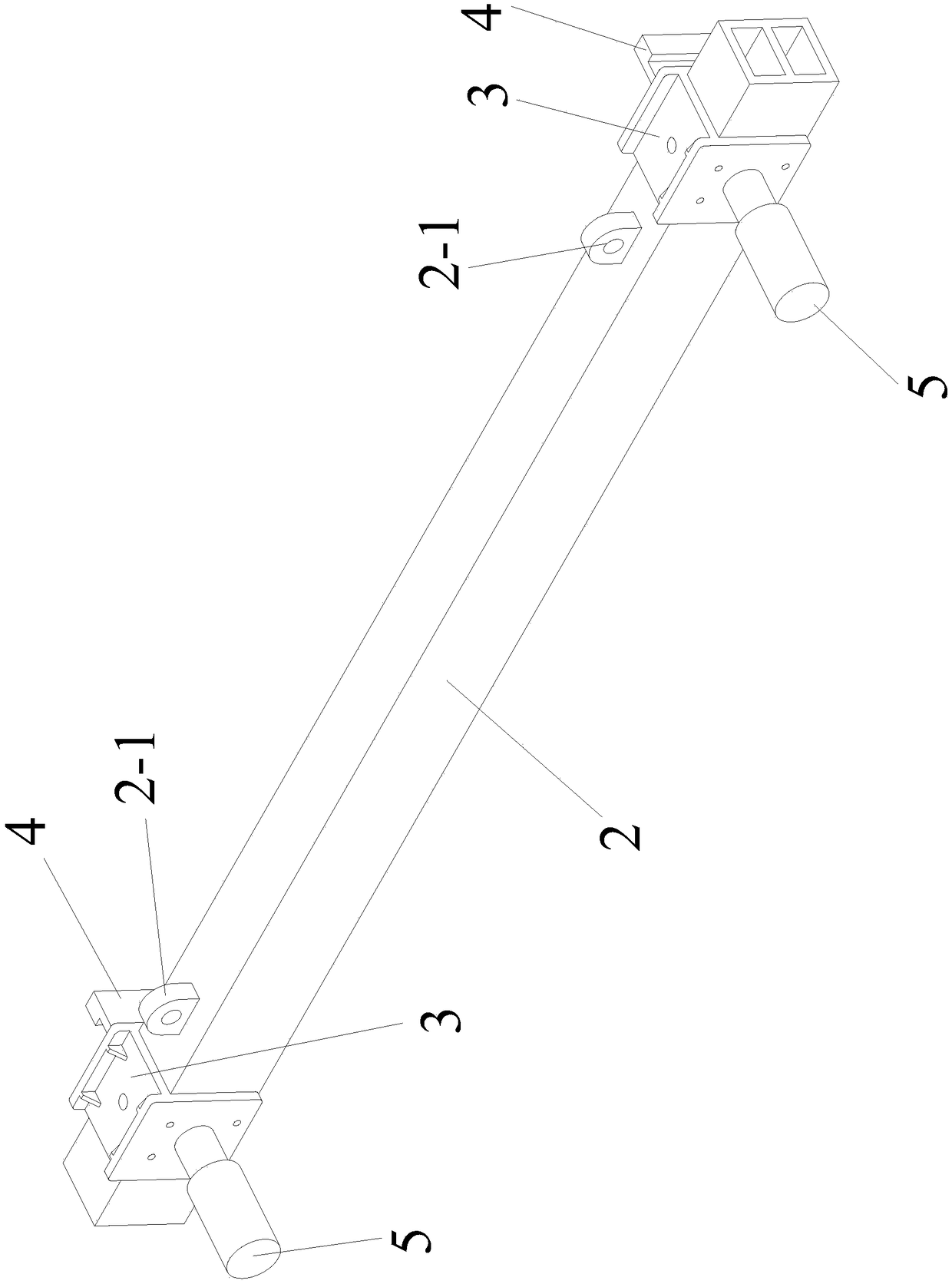

[0023] Such as Figure 2 to Figure 7 As shown, the vehicle body end wall static strength test loading device of the present invention includes a loading beam 2, two door-shaped beam hangers 3, two flange clamps 4 and two force cylinders 5, each door-shaped The front ends of the crossbeam hanger 3 are all fixedly connected with a corresponding flange holder 4, and the front ends of each door-shaped crossbeam hanger 3 are all fixedly connected with a corresponding force applying cylinder 5. Each door-shaped beam hanger 3 together with a corresponding flange holder 4 and a corresponding force applying cylinder 5 constitutes a positioning loading device. Each positioning loading device is fixedly connected to one end of the loading beam 2 through its door-shaped beam hanger 3, and the two positioning loading devices are arranged mirror-symmetrically with respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com