Machining technology of high-precision constant pressure valve and production line thereof

A processing technology and constant pressure valve technology, which is applied in the field of high precision constant pressure valve processing technology and high precision constant pressure valve production line, can solve the problems of increasing scrap rate, reducing output, and large pressure value fluctuation range, so as to increase output, The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments.

[0026] Example of processing technology for high precision constant pressure valve

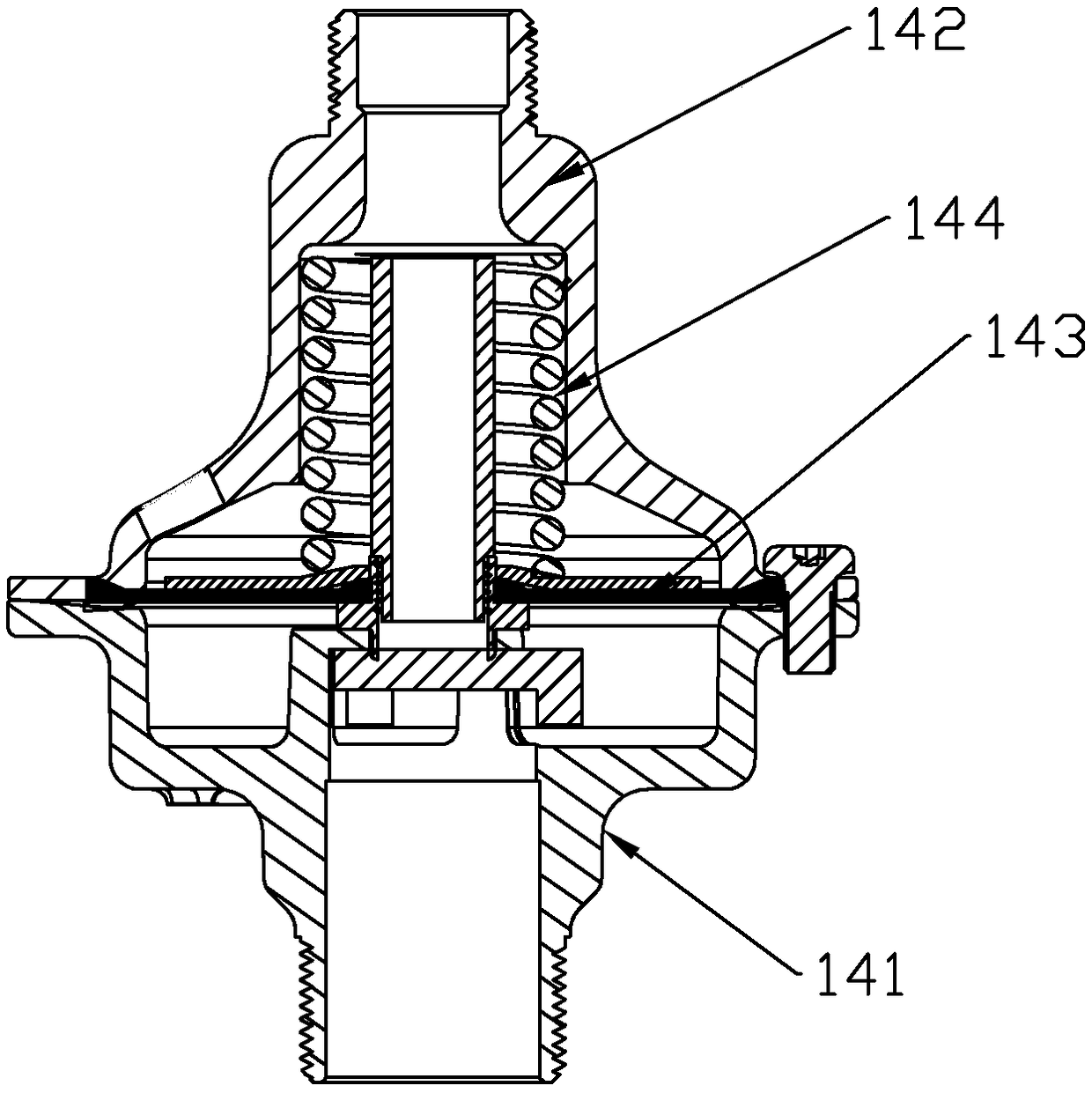

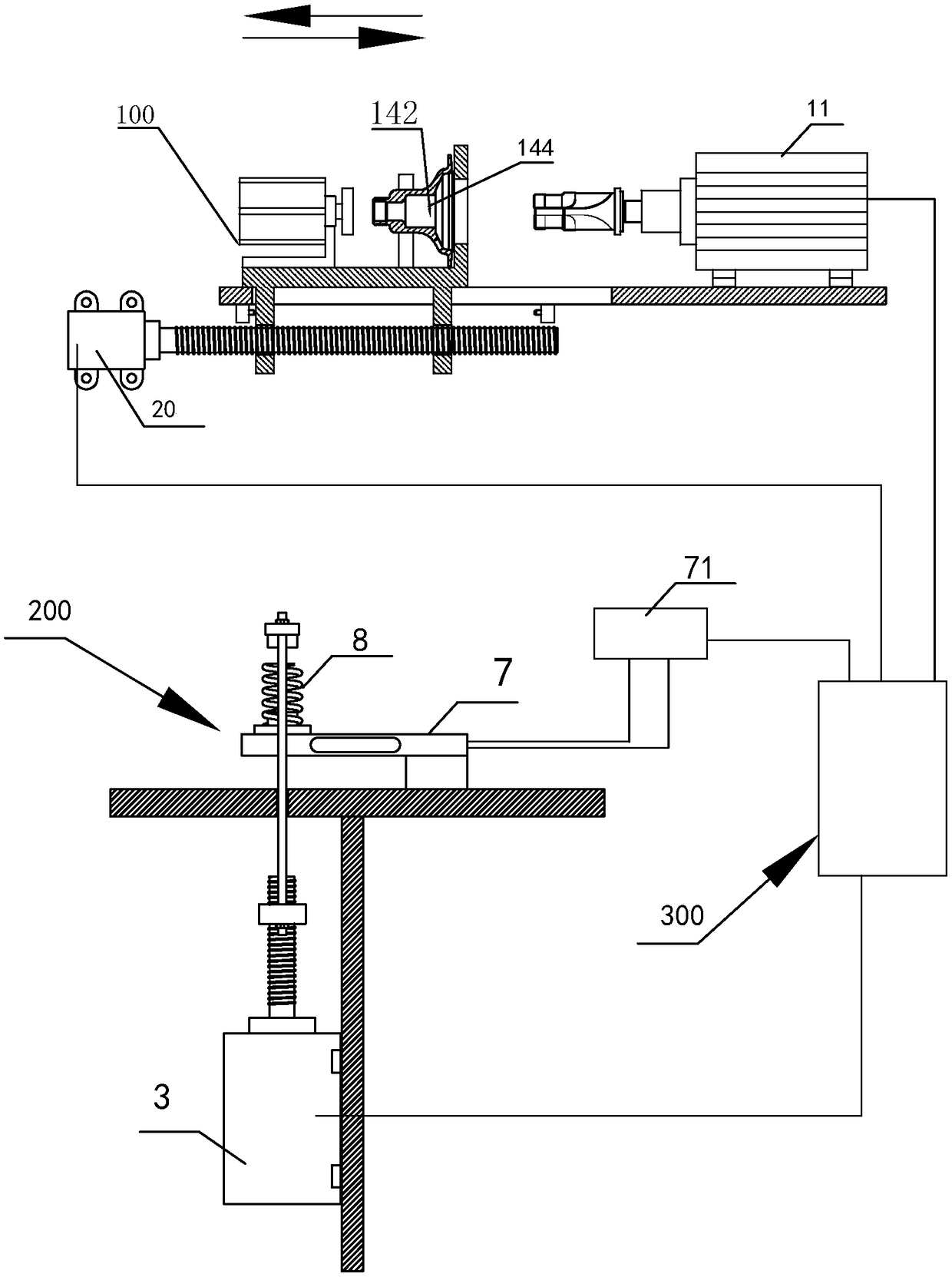

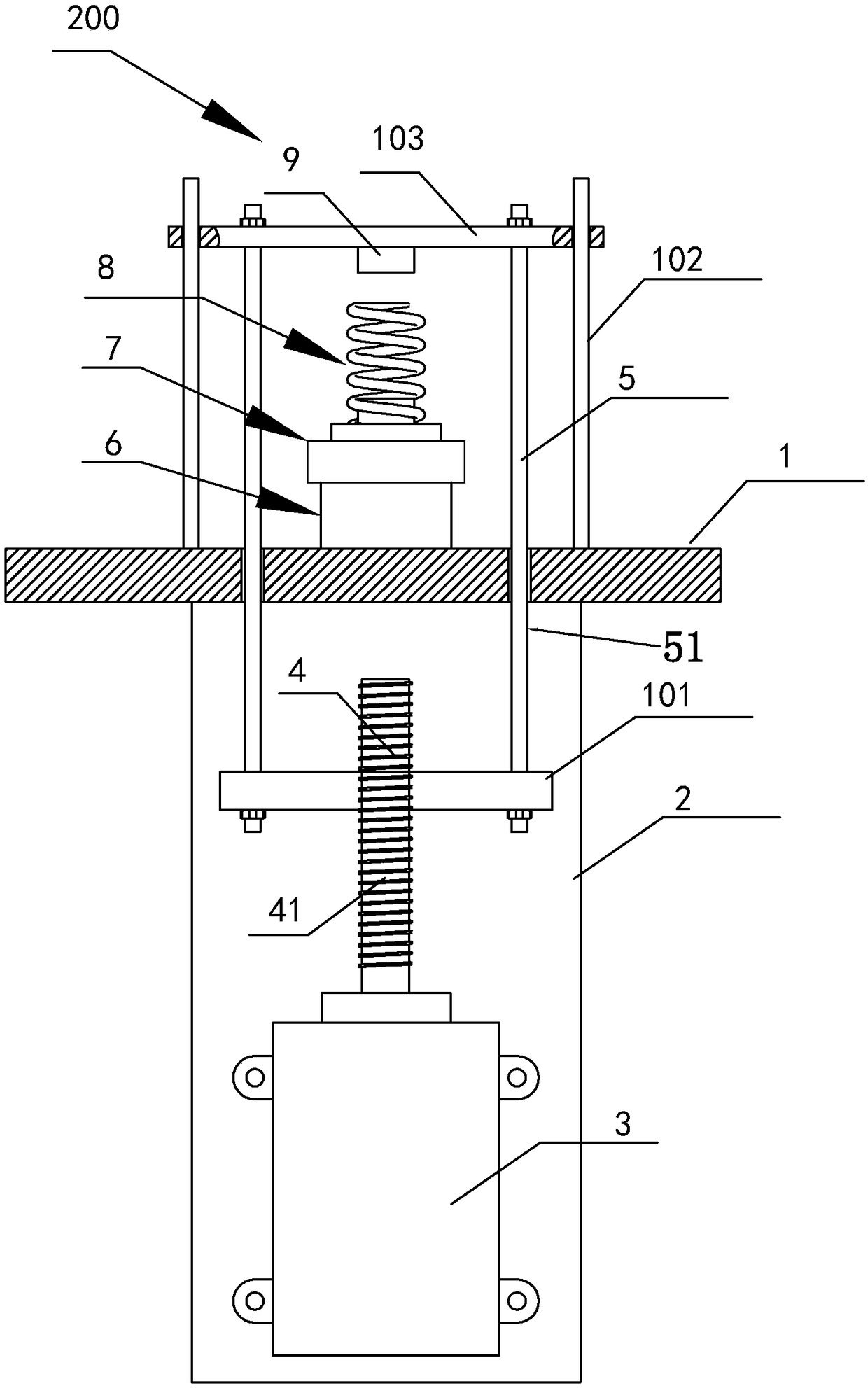

[0027] like figure 1As shown, the high-precision constant pressure valve in this embodiment includes an upper valve body 141, a lower valve body 142, a separating device 143 and an elastic device. The lower valve body 142 is separated into two independent spaces, and the elastic device includes a compression spring 8 and a compression spring hole 144 arranged on the lower valve body 142. The length value of the compression spring 8 in a free state is within the tolerance range. The length of the spring 8 in the free state is: 47±1.0mm, the number of turns: 7.5 turns; the tail of the spring is closed; the outer diameter: 24.2~24.5mm; the wire diameter: 3.2±0.10mm; when the spring is compressed to 32.2mm, The pressure is: 245±10N; the tail is ground flat, the inner holes at both ends are gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com