Method and device for on-line monitoring and pre-tightening force application of assembly of sandwich type longitudinal vibration transducer

A transducer, sandwich-type technology, applied in the direction of measuring the force applied to the control element, measuring device, instrument, etc., can solve the problems of inconvenient monitoring, reduce production efficiency and monitoring accuracy, and achieve the effect of optimizing the action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

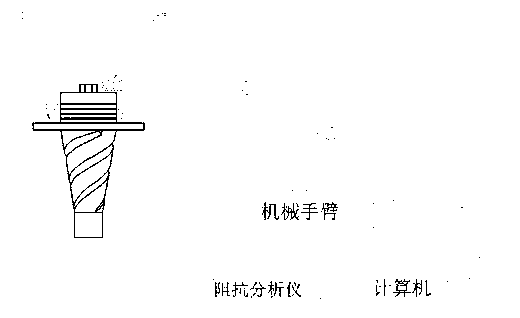

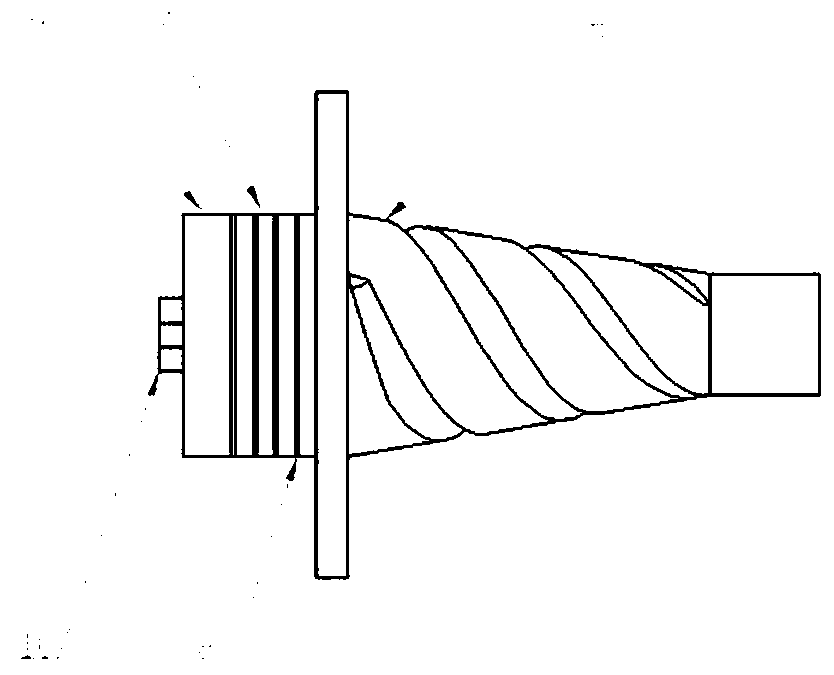

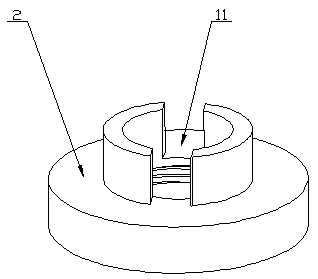

[0027] Example: see Figure 1-Figure 4 , in the figure, 1-vibration horn, 2-mold, 3-impedance analyzer, 4-computer, 5-mechanical arm, 6-horn, 7-piezoelectric ceramic sheet, 8-electrode sheet, 9- Back cover, 10-connecting bolts, 11-wall groove, 12-press piece, 13-cylindrical hole, 14-torque wrench.

[0028] The sandwich-type longitudinal vibration transducer assembly on-line monitoring and pre-tightening device includes the transducer and the horn 6. The transducer and the horn 6 adopt an integrated design, and the theoretical design of 1 / 4 wavelength is carried out respectively. A spiral groove with a helical structure is set on the conical transition section of the rod 6. The transducer is composed of four piezoelectric ceramic sheets 7, four electrode sheets 8, a rear end cover 9 and connecting bolts 10, and two adjacent piezoelectric ceramic sheets 7, one of the piezoelectric ceramic sheets 7 and the rear end cover 9 are provided with an electrode sheet 8, the piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com