Automatic sleeve-binding mechanism for bundling whistling tubes

A sliding mechanism and tube forming technology, which is applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of automatic ligation, inability to achieve elastic bands, etc., and achieves the effect of uniform output speed and easy initial positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with accompanying drawing, the present invention is further elaborated.

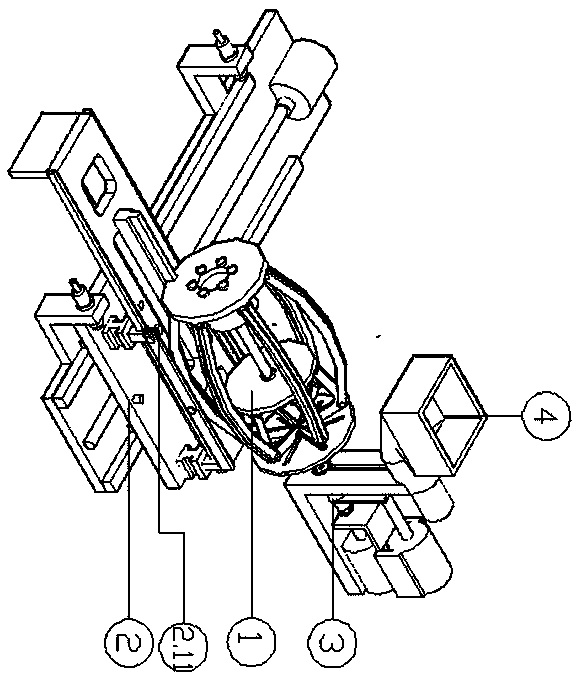

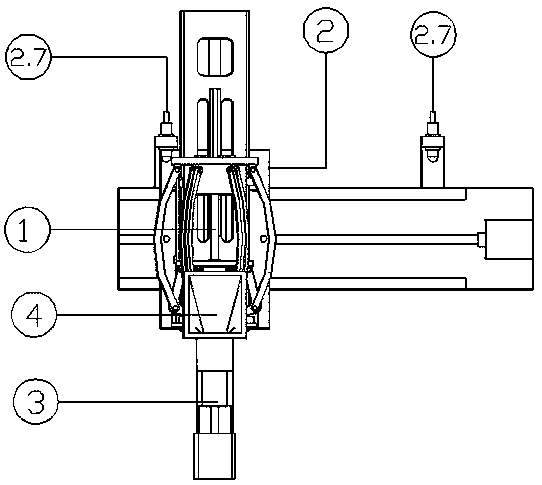

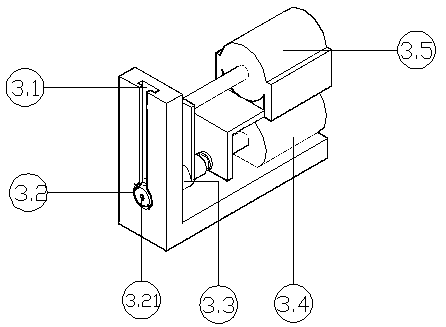

[0024] Such as figure 1 , 2 , 3, 4, 5, 6, and 7 show that the flute tubes are bundled into automatic banding mechanisms, including a banding mechanism 1, a sliding mechanism 2, an elastic band positioning upper sleeve mechanism 3 and an elastic band unloading mechanism 4, and bandage Mechanism 6 is opposite to the shaping mechanism. The ligation mechanism 1 includes a base 1.1, a guide plate 1.2, an elastic opening 1.3, a fixed plate 1.4, a telescopic mechanism 1.5, a push plate 1.6 and a moving plate 1.7, wherein the base 1.1 is fixed with a guide plate 1.2, and the guide plate 1.2 There are six guide holes 1.21 along the radial direction, and each guide hole 1.21 moves closer to and communicates with the center of the guide plate 1.2, and the guide plate 1.2 is also provided with an elastic opening 1.3, and the elastic opening 1.3 is evenly divided into six pieces And each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com