Hideout gun

A pistol and pocket technology, applied in the field of pocket pistols, can solve problems such as poor running stability, achieve the effect of improving reliability, ensuring overall performance, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

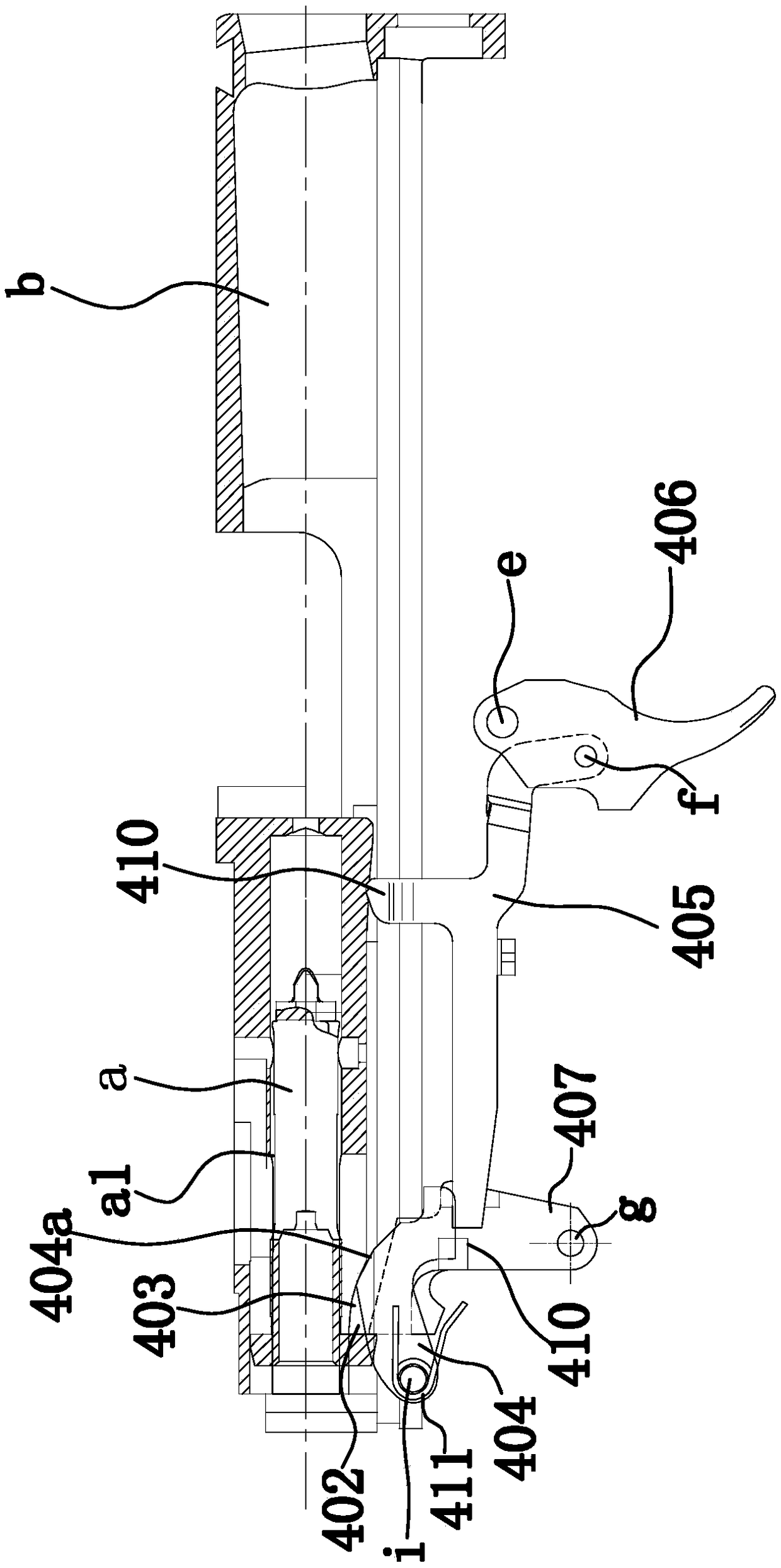

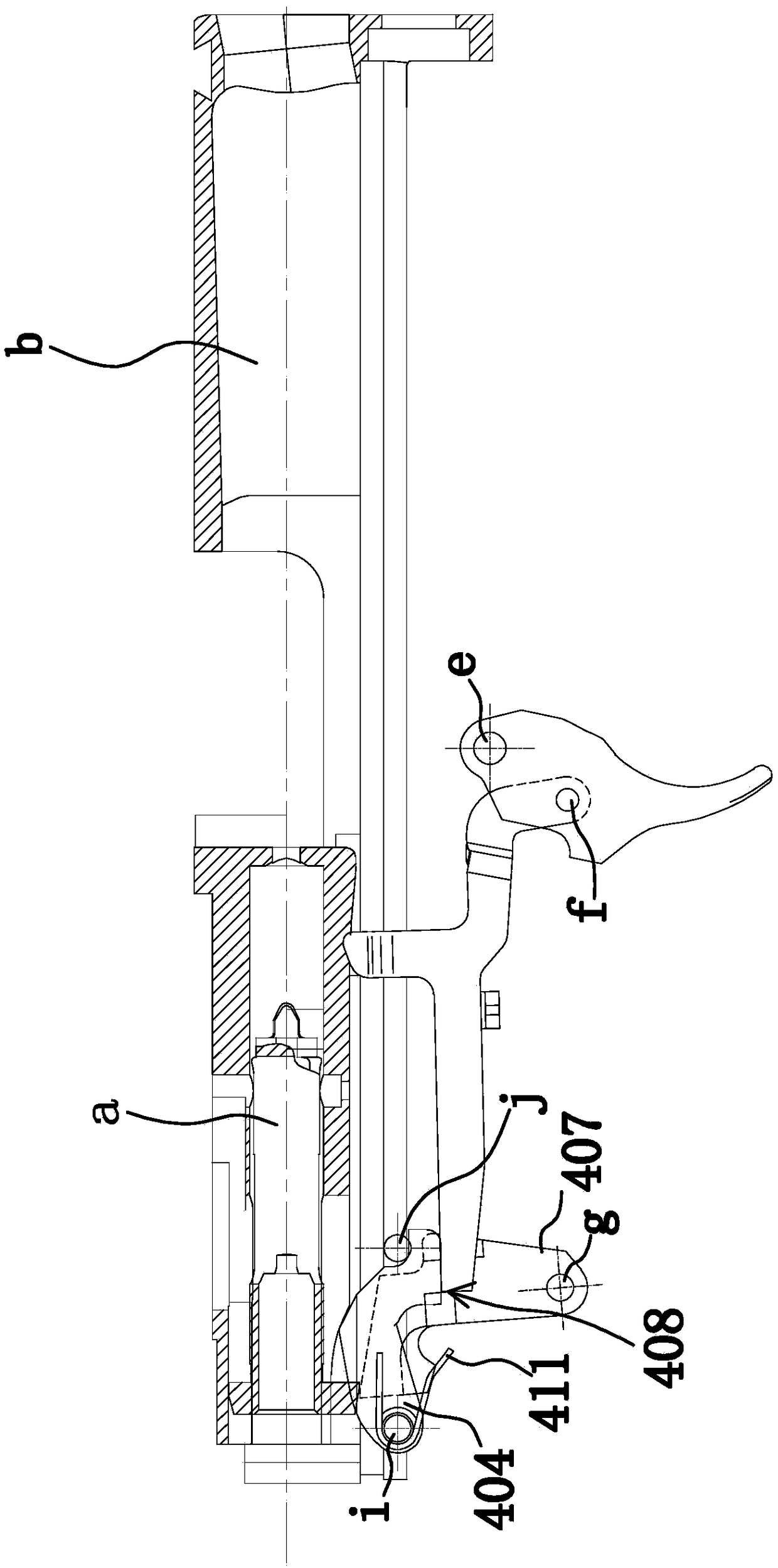

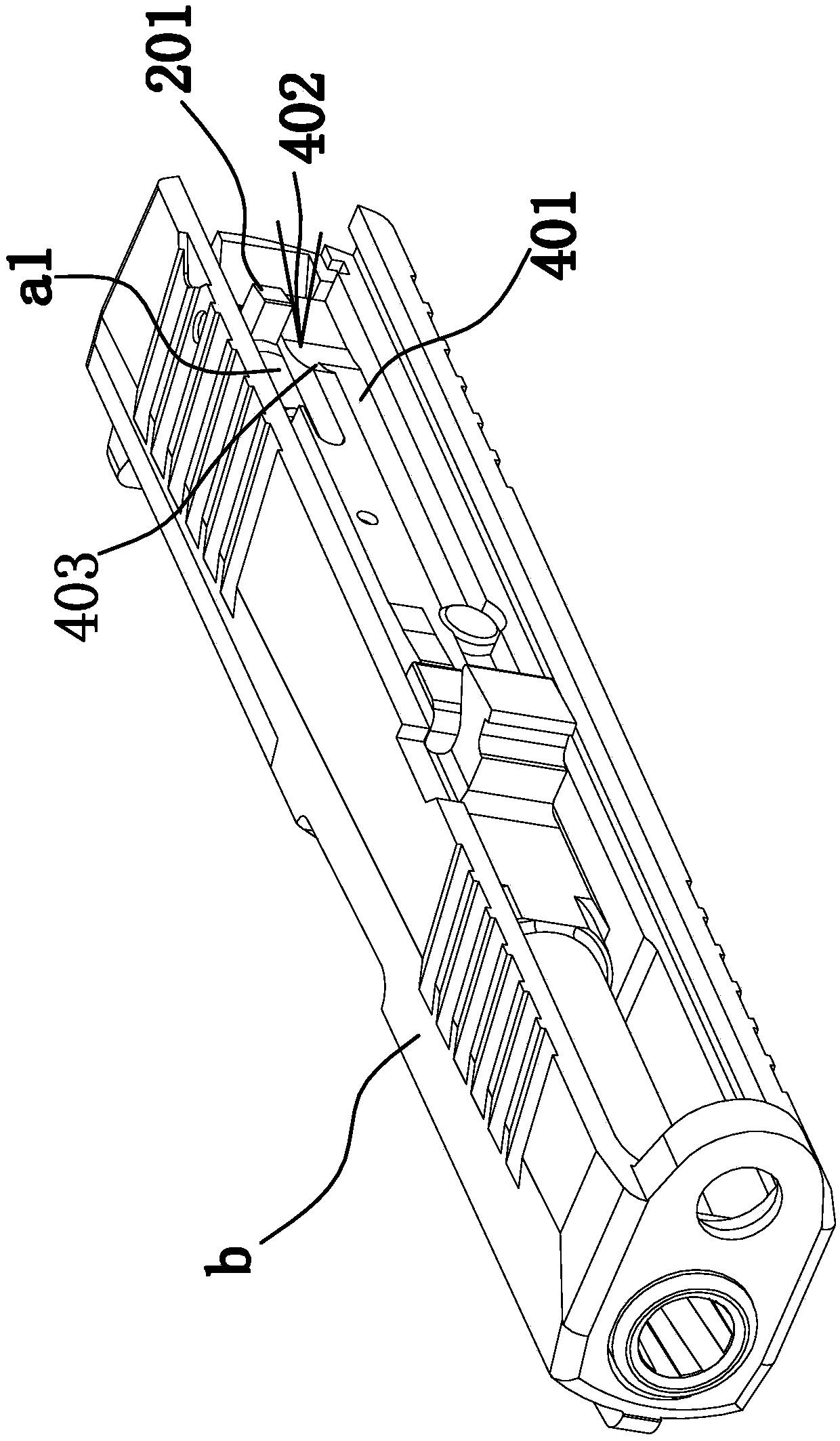

[0040] Such as Figures 1 to 22 As shown, the pocket pistol includes a grip seat c, on which a bolt body b and a support plate d are arranged, and a firing pin a is arranged in the bolt body b, and is characterized in that: the pistol also includes a firing mechanism, and the firing mechanism The mechanism includes a trigger 406, the upper part of the trigger 406 is connected with the trigger shaft e fixed on the support plate d, and its feature is that the lower part of the trigger 406 is connected with one end of the firing link 405 through the trigger safety shaft f, and the other end of the firing link 405 is The free end cooperates with the adjacent sear 407 through the push-and-turn composite surface 408, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com