Method to prevent gas channeling after liner cementing of high pressure gas well

A liner cementing and high-pressure gas technology, applied in wellbore/well components, earth-moving drilling, flushing wellbore, etc., can solve the problem of not being able to feed into the pipe string and connecting to the check valve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preventing gas channeling after liner cementing of a high-pressure gas well, which mainly includes: in the mud replacement stage of liner cementing, replacing heavy drilling fluid in the middle of the drilling tool to establish casing pressure in the next tripping stage; After the slurry replacement operation is completed, with the help of the casing pressure established by the heavy drilling fluid sent into the drilling tool, the surface back pressure pump and the throttle valve group work together to maintain the liquid level of the drilling tool water eye and achieve constant casing pressure tripping; Drill to the designed well depth, implement different ground return times for different annulus slurry columns at different stages of heavy drilling fluid in the drill tool, heavy drilling fluid exiting the pipe shoe, all the heavy drilling fluid reaching the annulus, and the heavy drilling fluid circulating out of the wellhead. Pressure compensation, so tha...

Embodiment 2

[0042] A method for preventing gas channeling after liner cementing of a high-pressure gas well, specifically comprising the following steps:

[0043] a. Test liner cementing operation pressure equivalent density ECD max ;

[0044] b. Circulating to reduce the drilling fluid density, and testing the equivalent gas density ECD of the liner cementing operation min ;

[0045] c. Control the pressure equivalent of the leakage layer at ECD min ~ECD max Inject cement slurry within the safety window;

[0046] d. After the replacement slurry is in place, it is sent into the drilling tool to the safety interface and circulated for waiting;

[0047] e. Turn on the pump to circulate the well.

[0048] In the step a, after the drilling is completed, the drilling tool is lowered to the bottom of the well, and after the aftereffect is removed by circulation, a pressure test is carried out.

[0049] The specific method of step a is: gradually increase the displacement, and through the a...

Embodiment 3

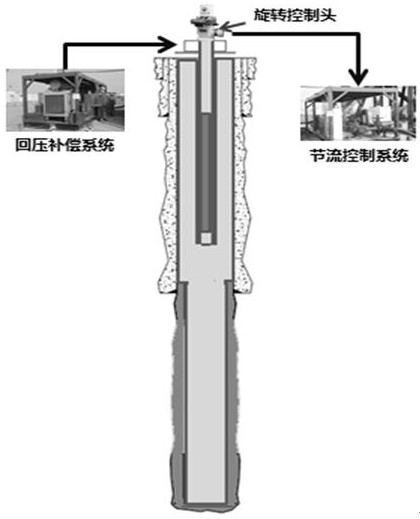

[0064] Attached below figure 1 and figure 2 The present invention is described in detail:

[0065] A high-pressure gas well in the western Sichuan area was subjected to 177.8mm liner suspension cementing operation, and the designed amount of cement slurry was injected for slurry replacement. Send into the drilling tool well section 0 ~ 3725.79m, the replaced mud contains 2.03g / cm 3 Original drilling fluid and 2.36g / cm 3 Weighted drilling fluid, where the weighted drilling fluid is sent into the drilling tool for a well section of 1800-2900m. After the slurry replacement is in place, turn off the rotary control head to pull out the drill, and the initial casing pressure is 4.9Mpa. During tripping, the back pressure pump continues to supplement the pressure in the annular space, the throttle valve group responds dynamically, and the liquid level in the hole of the drilling tool is unknown, and the casing pressure is always controlled at 4.9±0.1Mpa to achieve a constant casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com