A Gradient Nanostructure with Excellent Comprehensive High-Cycle and Low-Cycle Fatigue Properties

A nano-structure, low-cycle fatigue technology, applied in the field of fatigue performance enhancement of metal materials, can solve the problems of high-cycle fatigue performance limitation, low strength, and inability to guarantee anti-fatigue performance, and achieve the effect of improving comprehensive performance and synchronous optimization of fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

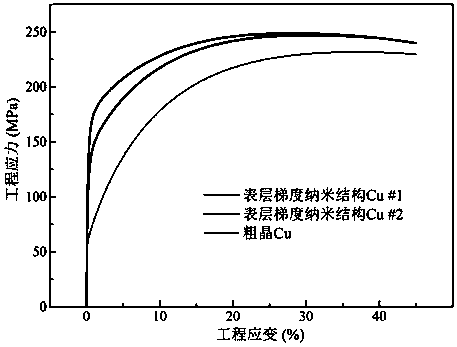

[0031] The Cu#1 sample with gradient nanostructure on the surface was obtained by mechanically treating the surface of the sample with a common lathe. The process parameters of the surface mechanical treatment are selected as follows: the diameter of the copper rod material is 6mm, and the rotating speed is 600r / min; In the pass, the indentation depth of the cemented carbide ball cutter head on the material surface is 40 μm, and the processing pass is 8. The treatment temperature is liquid nitrogen temperature ~ 173K.

[0032] As the depth from the surface increases, the grain size in this material presents a gradient trend of monotonous increase, and the average grain size gradually increases from 42nm in the outermost layer to 21μm in the core, such as figure 1 shown. The thicknesses of nanocrystalline and ultrafine crystalline layers on the surface are 20 μm and 200 μm, respectively.

[0033] In this embodiment, as the depth from the surface of the material increases, th...

Embodiment 2

[0037] The difference from Example 1 is:

[0038] Surface gradient nanostructured Cu#2 samples were obtained by surface mechanical treatment. The process parameters of the surface mechanical treatment are selected as follows: the diameter of the copper rod material is 6mm, and the rotating speed is 400r / min; In the pass, the indentation depth of the cemented carbide ball cutter head on the surface of the material is 40 μm, and the processing pass is 3 passes. The treatment temperature is liquid nitrogen temperature ~ 173K.

[0039] As the depth from the surface increases, the grain size in this material presents a monotonically increasing gradient trend, with the average grain size gradually increasing from 58nm to 21μm, as figure 2 shown. The thickness of surface nanocrystalline and ultrafine crystalline layer is 5 μm and 60 μm, which is smaller than that of surface gradient nanostructure Cu#1 sample.

[0040] In this embodiment, as the depth from the surface of the mate...

Embodiment 3

[0044] The difference from Example 1 is:

[0045] Gradient nanostructures were obtained on the surface of 304 stainless steel by surface mechanical treatment. The process parameters of the surface mechanical treatment are selected as follows: the diameter of the 304 stainless steel material is 6mm, and the rotating speed is 300r / min; In one treatment pass, the indentation depth of the cemented carbide ball cutter head on the surface of the material is 20 μm, and the treatment pass is 6 passes. The treatment temperature is room temperature.

[0046] As the depth from the surface increases, the grain size in this material presents a monotonically increasing gradient trend, and the average grain size changes from 30nm in the outermost layer ( Figure 8 ) gradually increases to 46 μm in the core. The thickness of the surface gradient nanostructure is 400 μm.

[0047] In this embodiment, as the distance from the surface of the material increases, the microhardness of the 304 st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com