Polylactic acid 3D printing material and preparation method and application thereof

A 3D printing and polylactic acid technology, applied in heat exchange materials, chemical instruments and methods, additive processing, etc., can solve the problems of no heat conduction or conduction, and achieve the effect of light weight, smooth surface and large market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

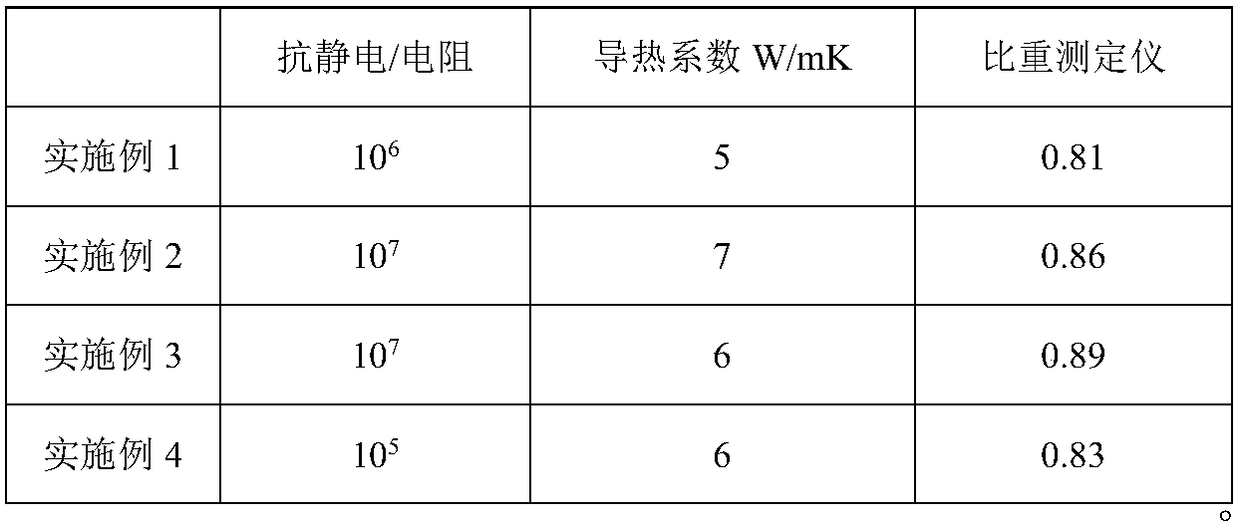

Embodiment 1

[0028] Embodiment 1 A kind of polylactic acid 3D printing material 1 and wire rod 1

[0029] A polylactic acid 3D printing material, the polylactic acid 3D printing material is composed of the following components in parts by mass: polylactic acid 65g, nitrogen-doped graphene 10g, antioxidant 0.5g, dispersant 4g, nucleating agent 0.5 g.

[0030] Wherein, the molecular weight of the polylactic acid is 40000.

[0031] Add the dried polylactic acid, nitrogen-doped graphene, antioxidant, dispersant and nucleating agent into a high-speed mixer, mix at a high speed for 3 minutes, and add the mixed materials into the barrel of a single-screw extruder at 180 Extrude and mix at ℃, air-dry, and pelletize to obtain polylactic acid particle 3D printing material.

[0032] Then dry the above-mentioned polylactic acid particle 3D printing material and add it to the plastic extruder. There is a water tank with ice water to fully cool the formed wire; it enters the tractor and rolls it up, ...

Embodiment 2

[0033] Embodiment 2 A kind of polylactic acid 3D printing material 2 and wire rod 2

[0034] A polylactic acid 3D printing material, the polylactic acid 3D printing material is composed of the following components in parts by mass: polylactic acid 30g, nitrogen-doped graphene 30g, antioxidant 0.5g, dispersant 3g, nucleating agent 0.1 g.

[0035] Wherein, the molecular weight of the polylactic acid is 100,000.

Embodiment 3

[0036] Embodiment 3 A kind of polylactic acid 3D printing material 3 and wire rod 3

[0037] A polylactic acid 3D printing material, the polylactic acid 3D printing material is composed of the following components in parts by mass: 90g of polylactic acid, 15g of nitrogen-doped graphene, 3g of antioxidant, 7g of dispersant, and 1g of nucleating agent.

[0038] Wherein, the molecular weight of the polylactic acid is 60000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com