Method for preparing anti-skid liquid

A production method and technology of anti-slip liquid are applied in the field of anti-slip of ceramic tiles, which can solve the problem of high cost of anti-slip treatment and achieve the effect of improving the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

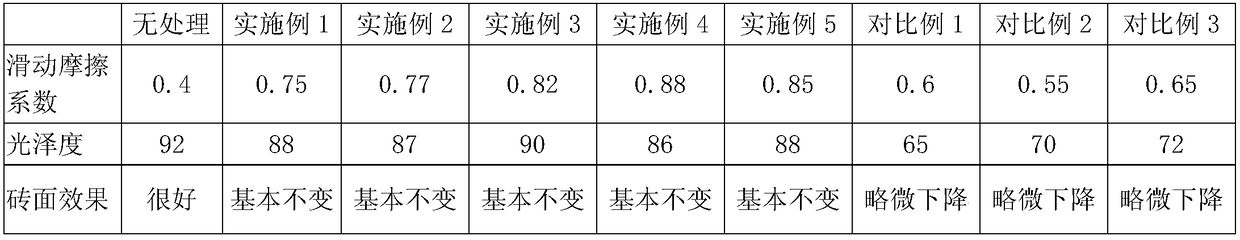

Examples

Embodiment 1

[0019] A kind of preparation method of anti-slip fluid, comprises the following steps:

[0020] Step 1: Prepare the following raw materials in parts by weight: 22 parts of fruit acid, 8 parts of acetic acid, 10 parts of sodium chloride, 6 parts of potassium carbonate, 8 parts of sodium dodecylbenzenesulfonate, 0.2 parts of alkylphenol polyoxyethylene ether 0.3 part of high carbon alcohol fatty acid ester complex, 0.5 part of urotropine and 45 parts of deionized water;

[0021] Step 2: Put deionized water in an electric heating stainless steel reaction kettle and heat it to 60°C, add fruit acid, acetic acid, sodium chloride, and potassium carbonate to dissolve in deionized water, and stir at 600 rpm for 15 minutes to obtain mixed solution A;

[0022] Step 3: Cool the mixed solution A to 40°C, add sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether, and stir at 300 rpm for 20 minutes to obtain mixed solution B;

[0023] Step 4: Cool the mixed solution B to 25°...

Embodiment 2

[0025] A kind of preparation method of anti-slip fluid, comprises the following steps:

[0026] Step 1: Prepare the following raw materials in parts by weight: 25 parts of fruit acid, 5 parts of acetic acid, 15 parts of sodium chloride, 5 parts of potassium carbonate, 10 parts of sodium dodecylbenzenesulfonate, 0.5 parts of alkylphenol polyoxyethylene ether 1 part, 1 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.5 part of urotropine and 38 parts of deionized water;

[0027] Step 2: Put deionized water in an electric heating stainless steel reaction kettle and heat it to 65°C, add fruit acid, acetic acid, sodium chloride, and potassium carbonate to dissolve in deionized water, and stir at 650 rpm for 15 minutes to obtain mixed solution A;

[0028] Step 3: Cool the mixed solution A to 45° C., add sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether, and stir at a speed of 350 rpm for 20 minutes to obtain a mixed solution B;

[0029] Step 4: ...

Embodiment 3

[0031] A kind of preparation method of anti-slip fluid, comprises the following steps:

[0032] Step 1: Prepare the following raw materials in parts by weight: 30 parts of fruit acid, 5 parts of acetic acid, 10 parts of sodium chloride, 5 parts of potassium carbonate, 15 parts of sodium dodecylbenzenesulfonate, 1 part of alkylphenol polyoxyethylene ether 0.5 part of polyoxypropylene polyoxyethylene glyceryl ether, 0.5 part of urotropine and 33 parts of deionized water;

[0033] Step 2: Put deionized water in an electric heating stainless steel reaction kettle and heat it to 70°C, add fruit acid, acetic acid, sodium chloride, and potassium carbonate to dissolve in deionized water, and stir at a speed of 700 rpm for 18 minutes to obtain mixed solution A;

[0034] Step 3: Cool the mixed solution A to 50°C, add sodium dodecylbenzenesulfonate and alkylphenol polyoxyethylene ether, and stir at 400 rpm for 18 minutes to obtain mixed solution B;

[0035] Step 4: Cool the mixed liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com