Method for preventing water purification diaphragm from being damaged

A technology of water purification membrane and carrying box, which is applied in the direction of chemical instruments and methods, multi-stage water treatment, water/sewage treatment, etc., and can solve the problems such as the need for protection of water purification membrane components, so as to increase the pressure and prevent loosening and unloading , the effect of reducing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

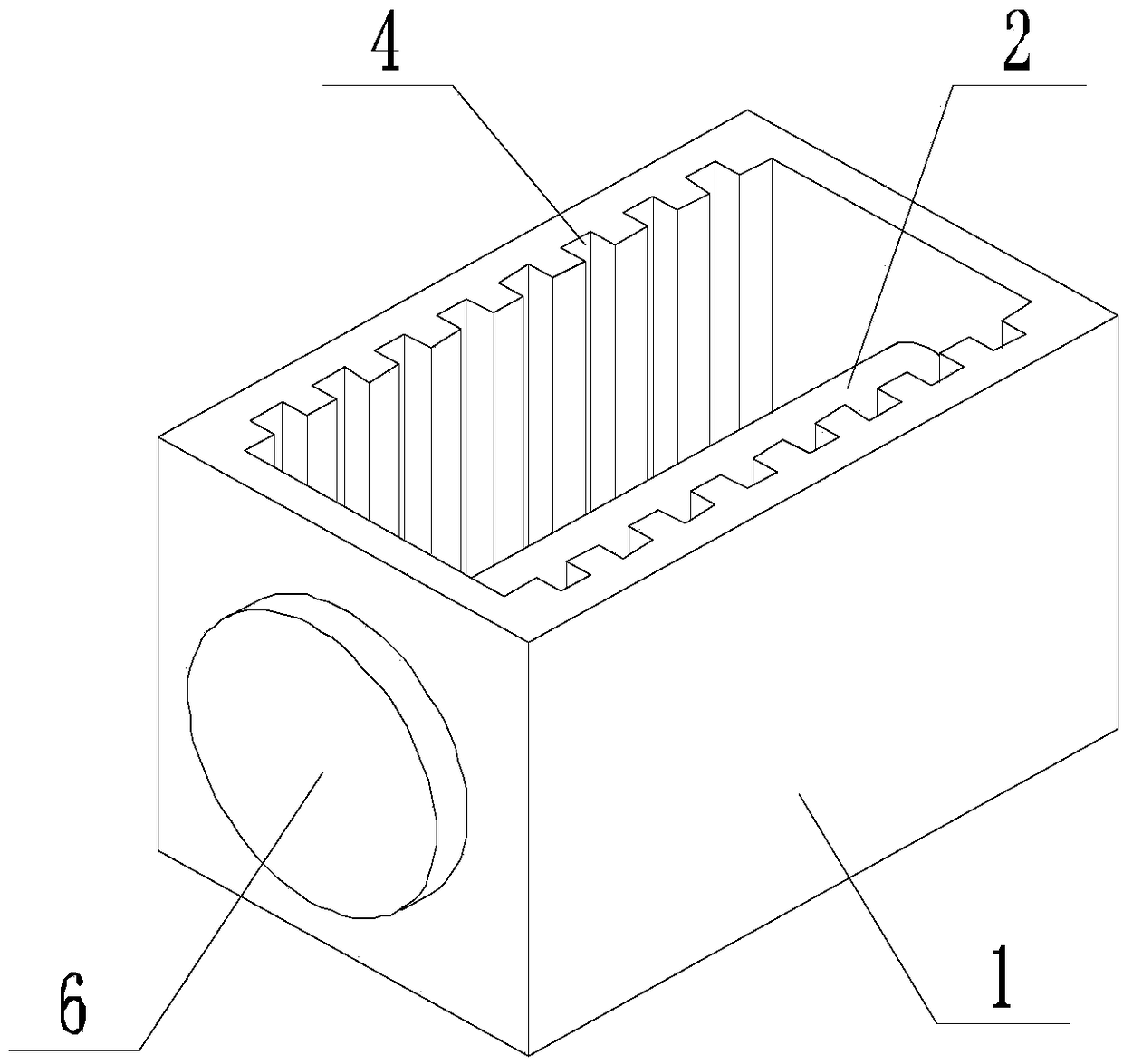

[0035] Such as Figure 1-Figure 5 As shown, the present invention avoids the method that water purification membrane is damaged, comprises the steps:

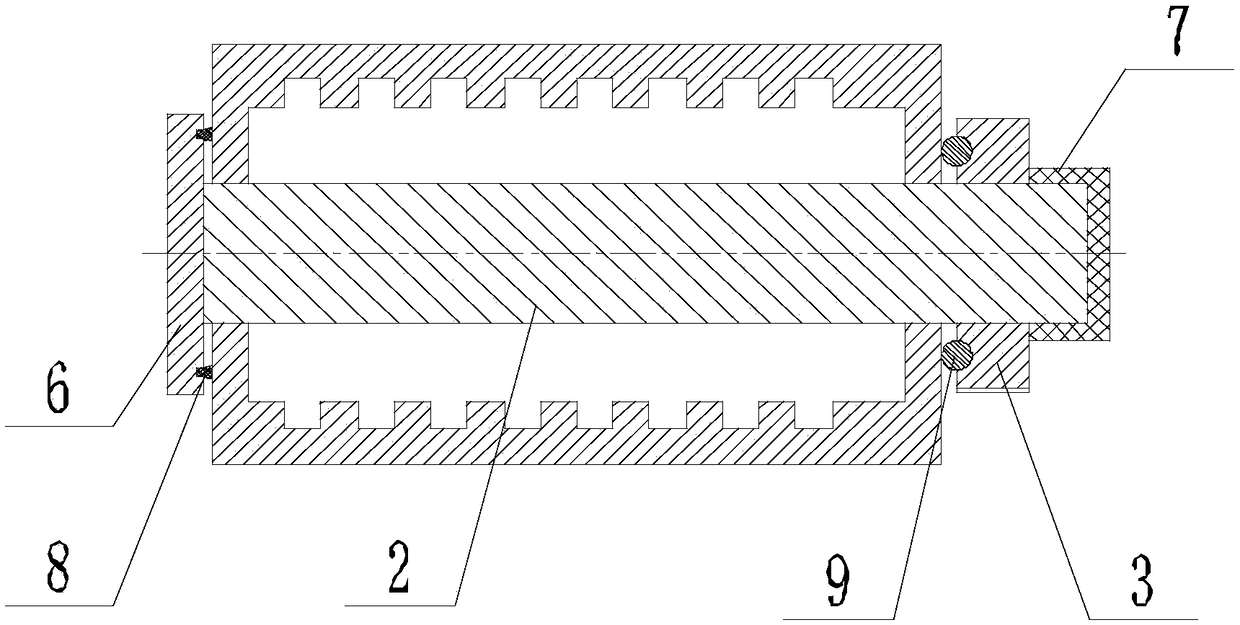

[0036] Step A: Loosen the nut 3 until the nut 3 retreats from the screw rod 2;

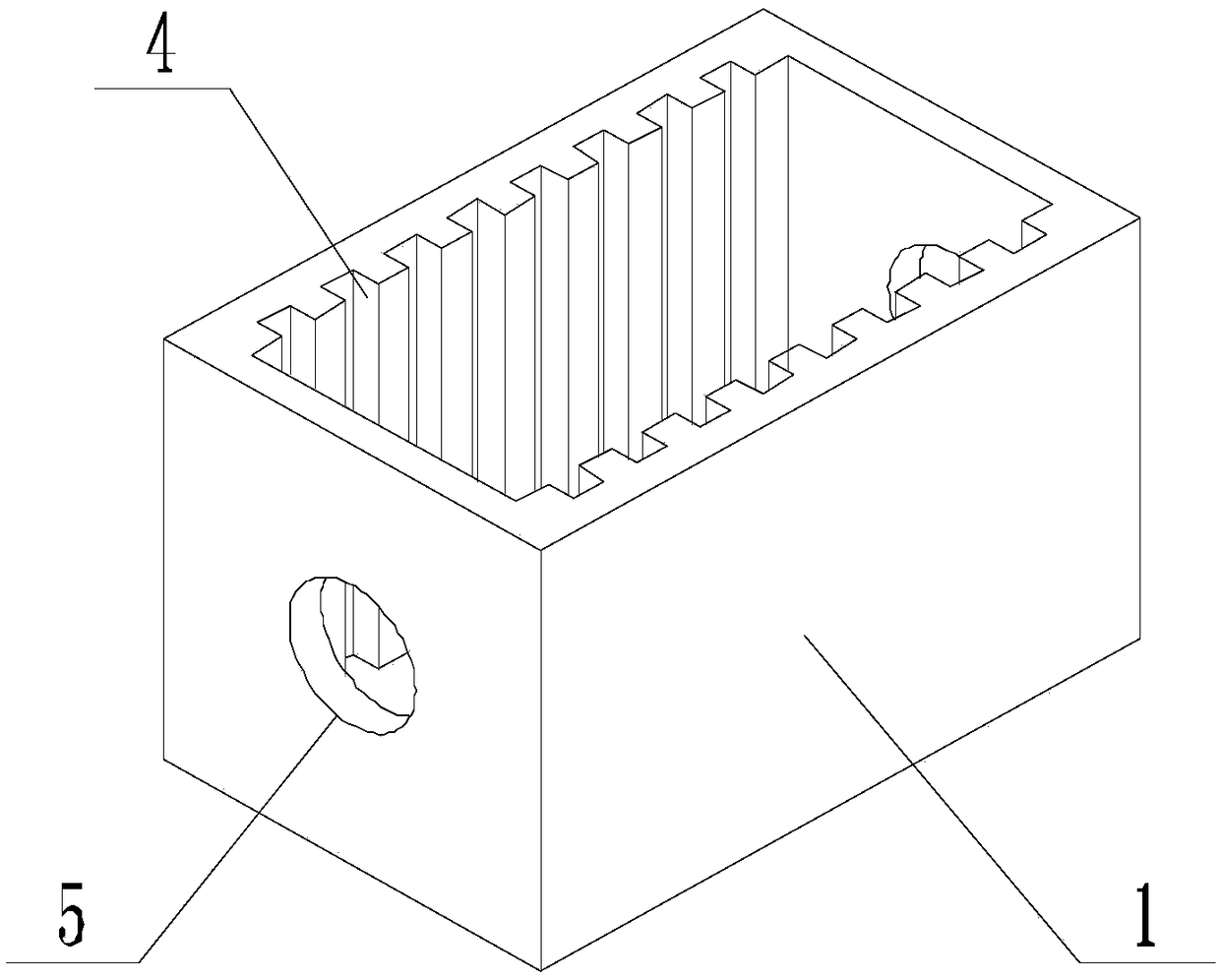

[0037] Step B: move the stop plate 6 away from the carrying box 1 until the screw 2 withdraws from the through hole 5;

[0038] Step C: Place each water purification membrane assembly in the carrying box 1 in turn, so that the two ends of the water purification membrane assembly are respectively located in a pair of opposite guide grooves 4, and the bottom of the water purification membrane assembly is in contact with the carrying box 1 The bottom of the cavity wall is in contact, and the through hole on the water purification membrane assembly is parallel to the axis of the through hole 5 on the carrying box 1;

[0039] Step D: Pass the end of the screw 2 away from the retaining plate 6 through the through hole 5 on one side of the carrying box ...

Embodiment 2

[0046] Preferably, the distance between the bottom of the guide groove 4 on the inner wall of one side and the bottom of the corresponding guide groove 4 on the other side of the groove wall is consistent with the width of the water purification membrane assembly, and the through hole on the carrying box 1 5 The distance from the bottom of the inner cavity wall of the carrying box 1 is consistent with the size of the through hole on the water purification membrane assembly from the bottom of itself.

Embodiment 3

[0048] An annular groove is arranged on the side of the baffle plate 6 close to the carrier box 1, the axis of the annular groove coincides with the axis of the baffle plate 6, and a sealing ring 8 is embedded in the annular groove, when the baffle plate 6 and the nut 3 are in contact with the bearing box 1, when the nut 3 is screwed relative to the screw rod 2, the sealing ring 8 can be compressed and deformed.

[0049] The compression deformation of the sealing ring 8 increases the axial pressure of the thread between the nut 3 and the screw rod 2 to prevent the nut 3 from being loosened and improves the stability of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com