Warp-feeding device applicable to no-bending fabric weaving

A non-bending fabric, let-off technology, used in textiles and papermaking, weaving, looms, etc., can solve the problems of maintaining flat yarn cross-sectional shape, frequent yarn friction, mutual extrusion, etc., to achieve uniform yarn tension, reduce Wear and breakage, avoid the effect of mutual friction and extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

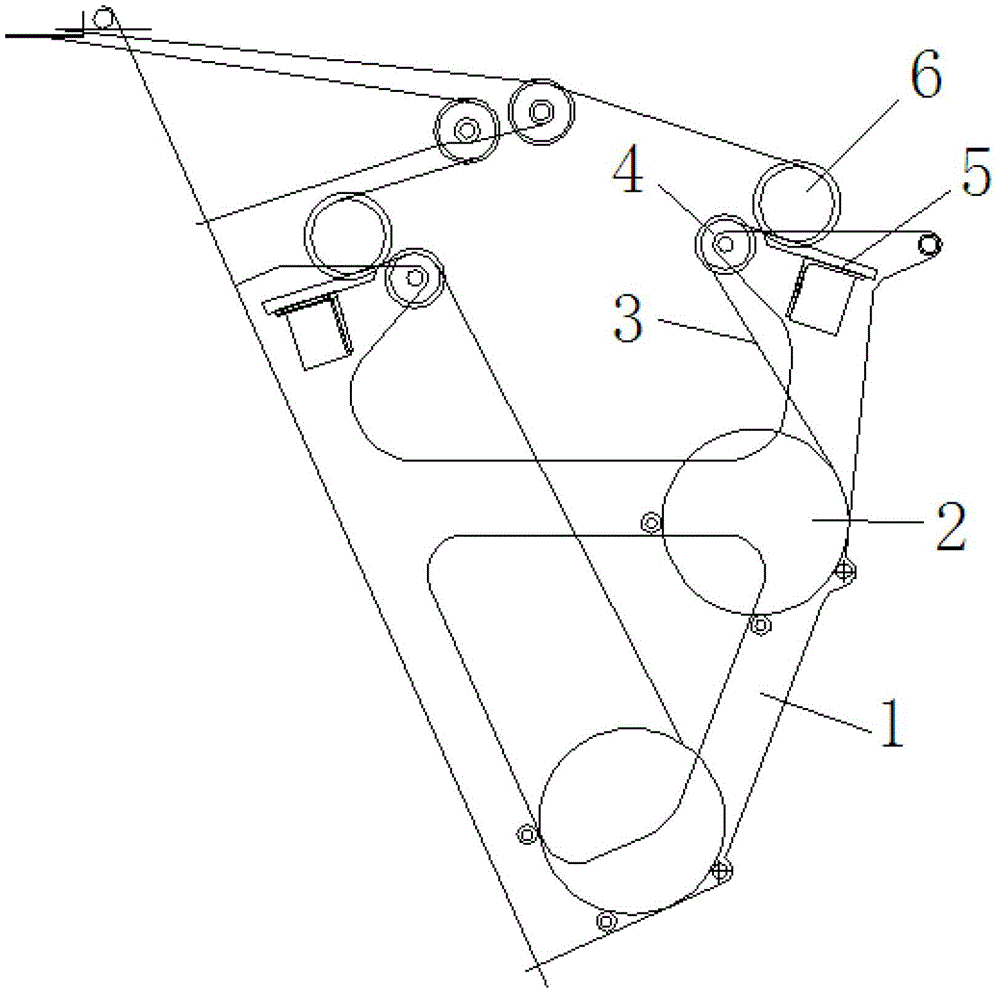

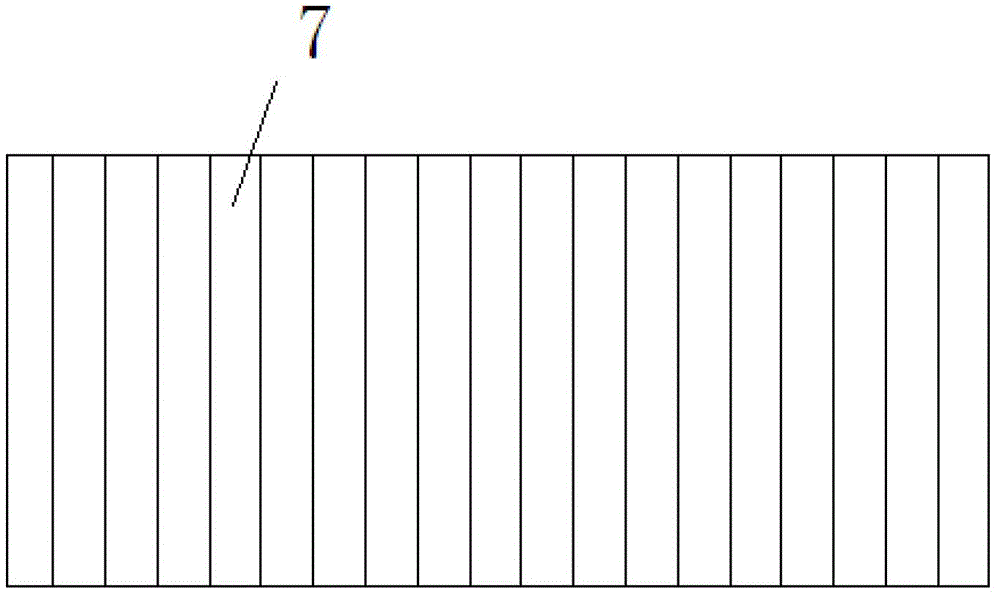

[0020] Such as Figures 1 to 2 , a loom warp let-off device suitable for weaving non-bending fabrics, comprising a warp supply device 2, the warp supply device is composed of a number of single yarn shafts 7 with the same specifications and independent of each other, each single yarn shaft 7 Winding a single bundle of warp yarns 3, the single yarn shafts 7 are arranged in close proximity to each other and parallel to each other and pass through the same support shaft to be fixed on the loom base 1, which together constitute a warp yarn supply device passing through the same heald frame on the non-bending fabric weaving system.

[0021] The loom warp let-off device suitable for non-bending fabric weaving also includes a warp tension control device matched with the warp supply device 2, and the warp tension control device includes a circular tension weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com