An anti-sway device for lifting of a large-scale liquid tank and a matching method thereof

A liquid tank hoisting and anti-sway technology, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of large damage to the hull of the tank, large surface area of large liquid tanks, and shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

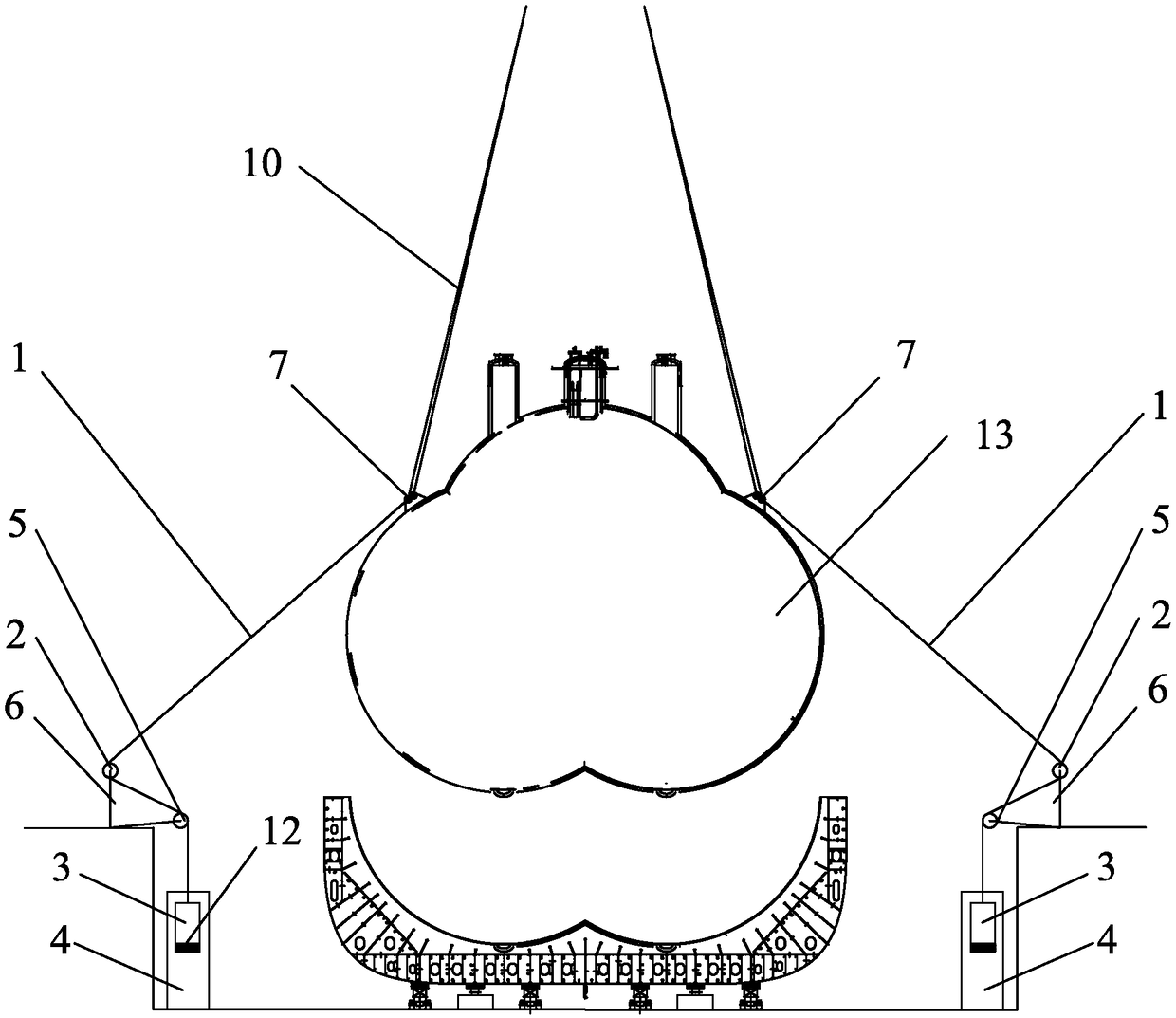

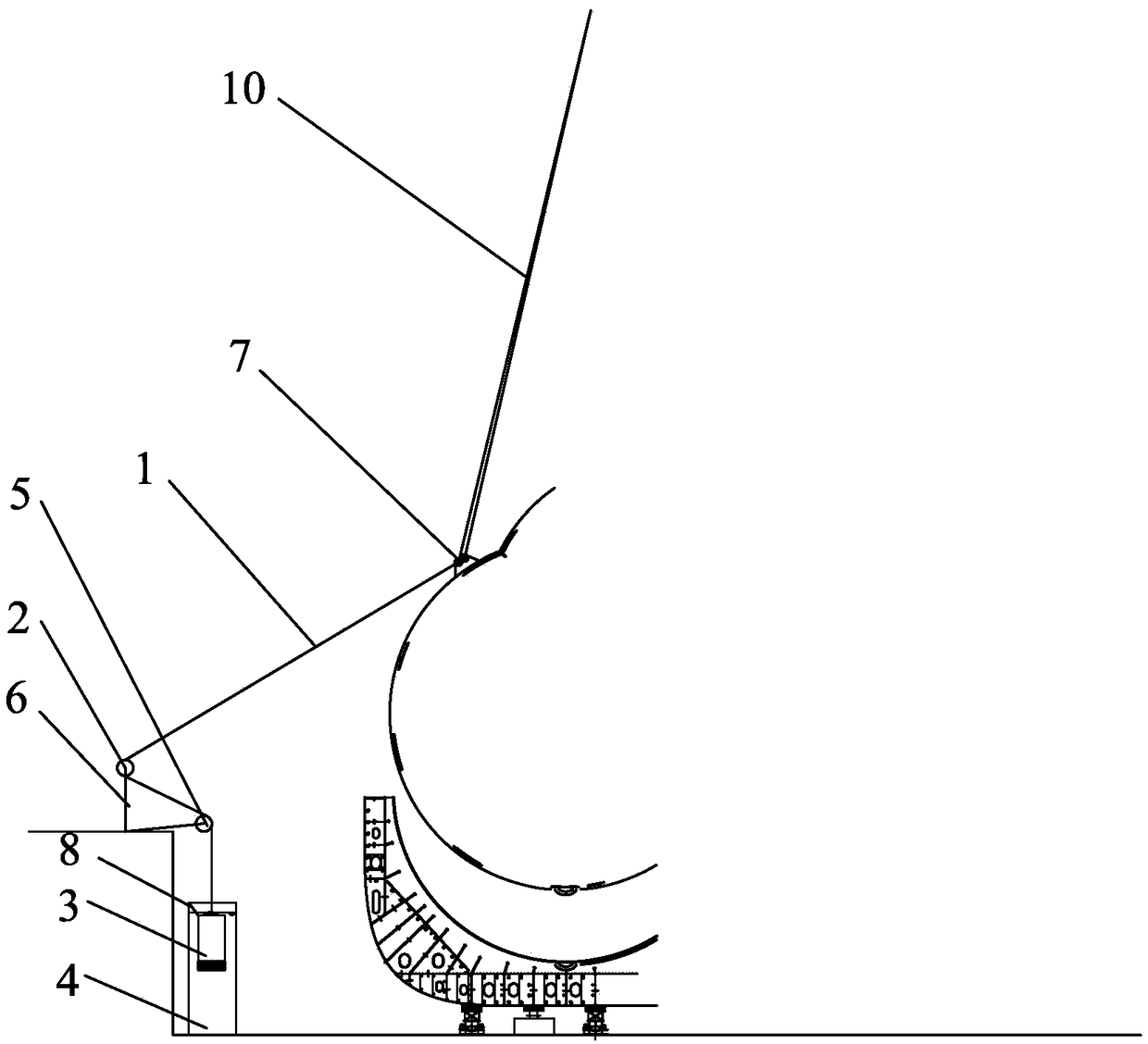

[0053] Embodiment 1: The situation where a large liquid tank is lowered into a cargo hold located in a small dock

[0054] Such as Figure 6 As shown, the system parameters are: the maximum wind force of the sixth-level wind is 7.14 tons. Four lifting lugs 11 are arranged on the wide body surface of both sides of the liquid tank to be placed in the cargo hold, and the lifting lugs 11 are respectively connected with four sets of steel wire ropes 1 in the present invention. Four cubic meters of floating tank 3 volumes, four tons of dead weight, one meter high, two meters long and wide, and the center of gravity is at the bottom. Water tank 48*3*3 meters, adjustable rope length 7 meters>(28.23-22.42) (actual rope release amount), fixed pulley block 6 must bear the pulling force and be 8 tons.

[0055] Wire rope 1 and fixed pulley block 6 are connected to the wire rope at the lugs on both sides of the tank body, and wire rope 1 bypasses the first pulley 2 and the second pulley 5...

Embodiment 2

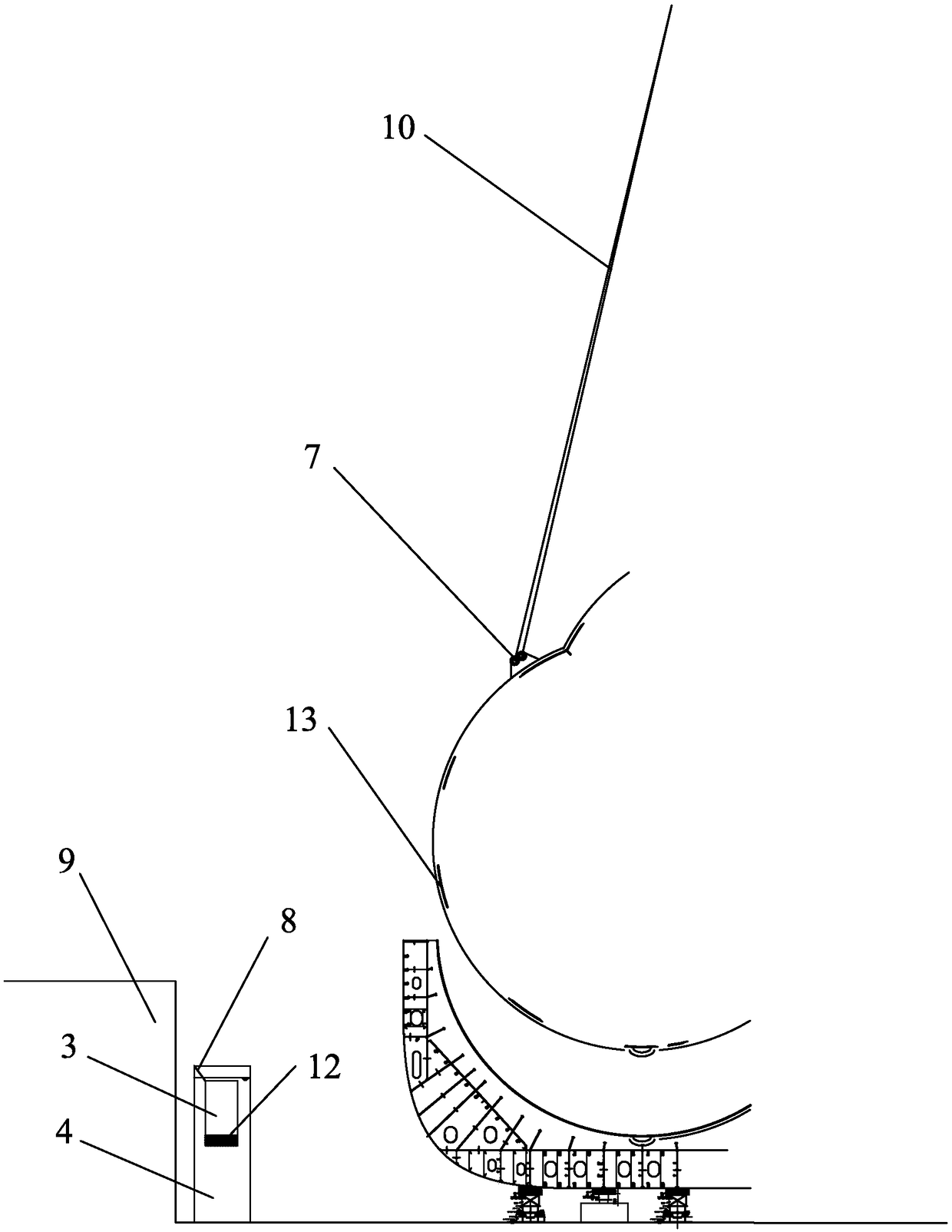

[0057] Embodiment 2: The situation in which a large liquid tank is lowered into a cargo hold located in a large dock

[0058] Such as Figure 7 As shown, there are two cargo holds of liquid tanks to be installed symmetrically in the large dock. The maximum wind force of the sixth-level wind is 7.14 tons. Four lifting lugs 11 are arranged on the wide body surface of both sides of the liquid tank to be placed in the cargo hold, and the lifting lugs 11 are respectively connected with four sets of steel wire ropes 1 in the present invention. Four cubic meters of floating tank 3 volumes, four tons of dead weight, one meter high, two meters long and wide, and the center of gravity is at the bottom. Water tank 48*3*3 meters, adjustable rope length 7 meters>(28.23-22.42) (actual rope release amount), fixed pulley block 6 must bear the pulling force and be 8 tons.

[0059] Wire rope 1 and fixed pulley block 6 are connected to the wire rope at the lugs on both sides of the tank body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com