Full-automatic servo paper feeder

A paper feeder, fully automatic technology, applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problems of reducing the work intensity of workers, easy to make mistakes, slow processing speed, etc., and achieve the effect of avoiding processing accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

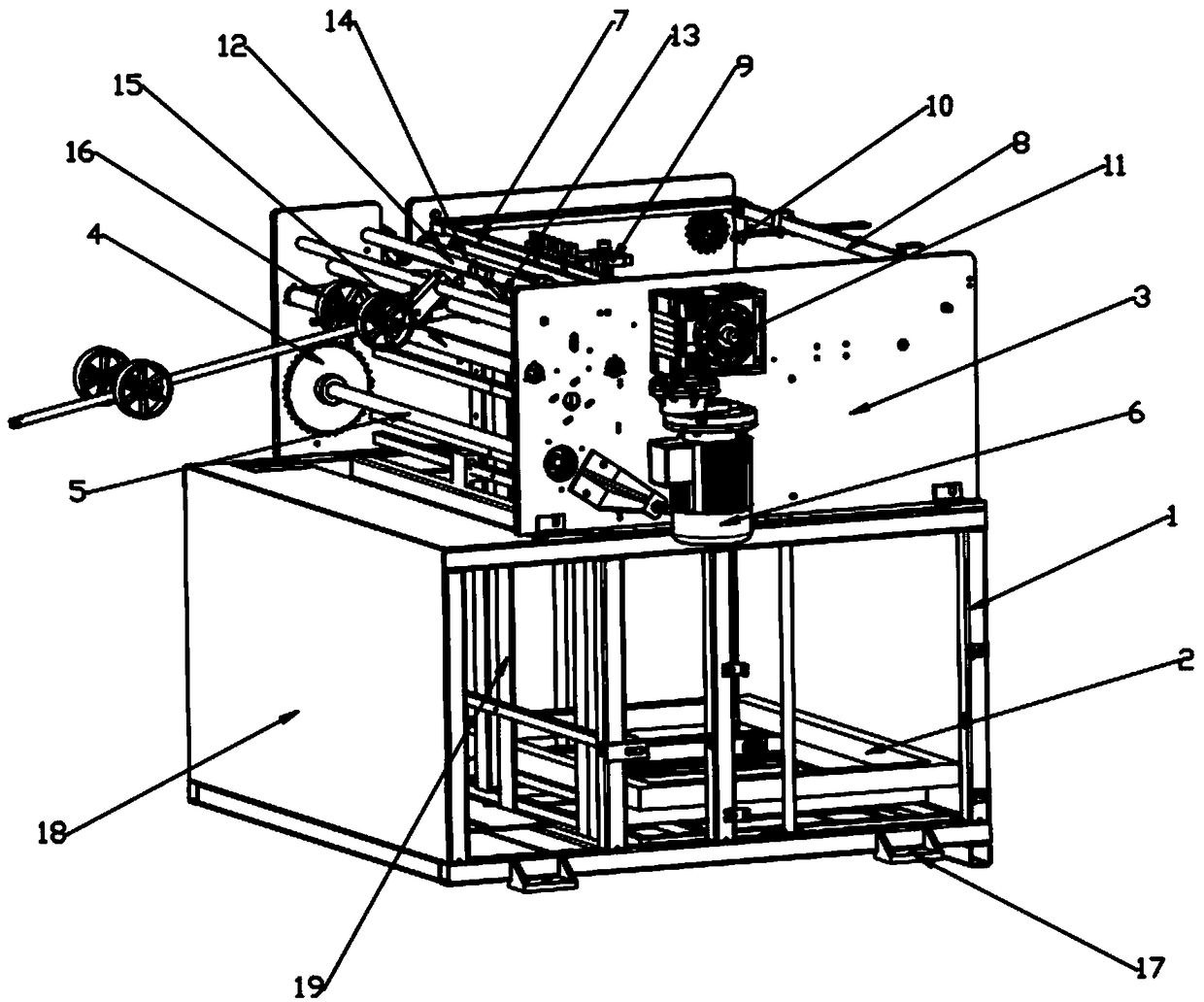

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] A fully automatic servo paper feeding machine, comprising a frame 1, a paper feeding platform 2 is provided inside the frame 1, baffles 3 are provided on both sides of the upper end of the frame 1, and chains are provided on the inside of the baffle 3 Wheel 4, the sprocket 4 is connected to the axle 5 installed on the baffle 3, the outside of the baffle 3 is provided with a motor 6, the motor 6 drives the sprocket 4 and the axle 5 to run, the The sprocket 4 lifts the paper feeding platform 2 through a hinge, and the inside of the baffle plate 3 is provided with a front horizontal plate 7 and a rear horizontal plate 8, and an encoder 9 is installed on the described front horizontal plate 7, and the described rear horizontal plate 8 is equipped with a photoelectric sensor 10, the outer side of the baffle plate 3 is provided with a reducer 11, the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com