Screw

A screw and stud technology, applied in the field of screw, can solve the problems of untimely detection of errors and low precision, and achieve the effects of stable structure, convenient adjustment and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

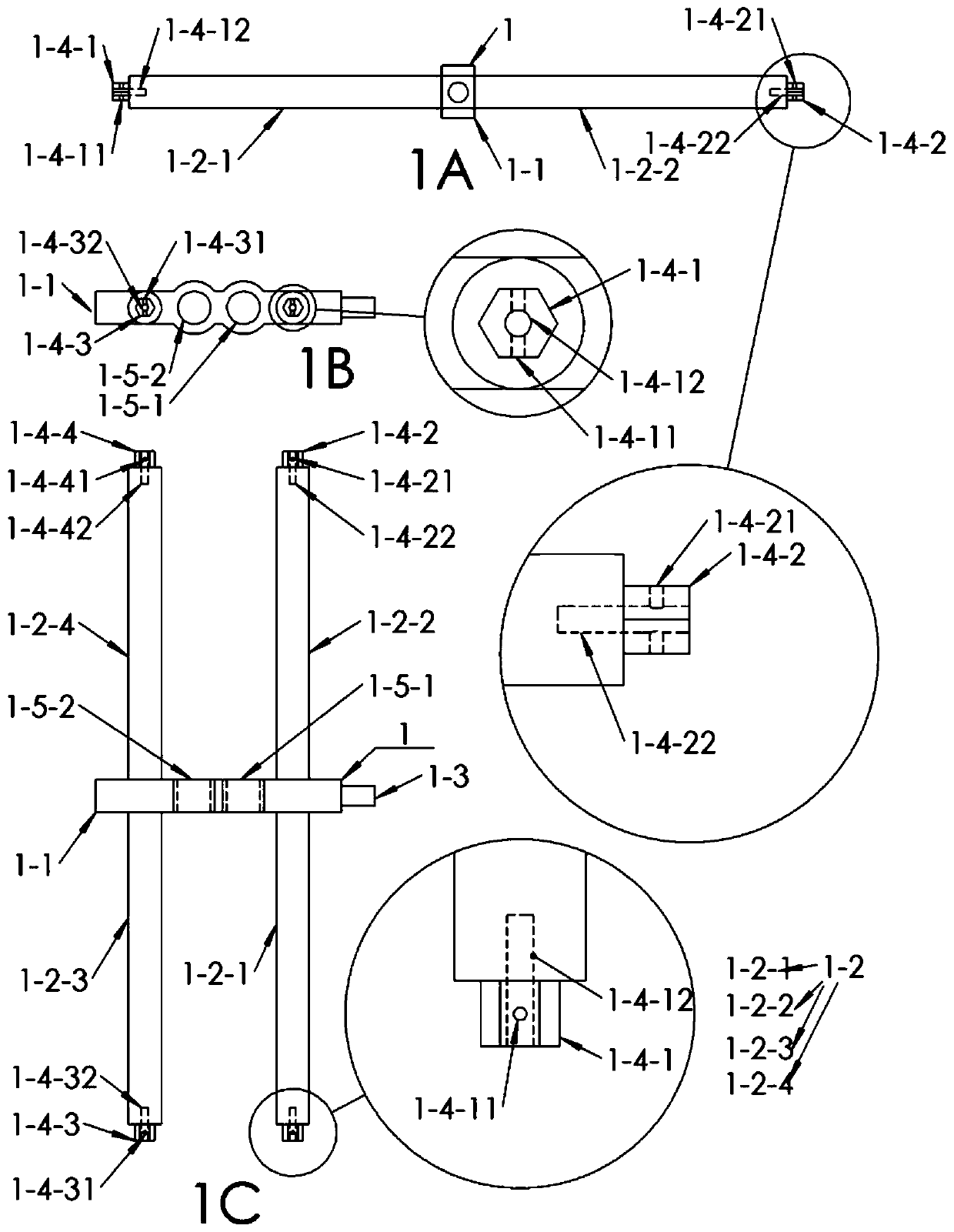

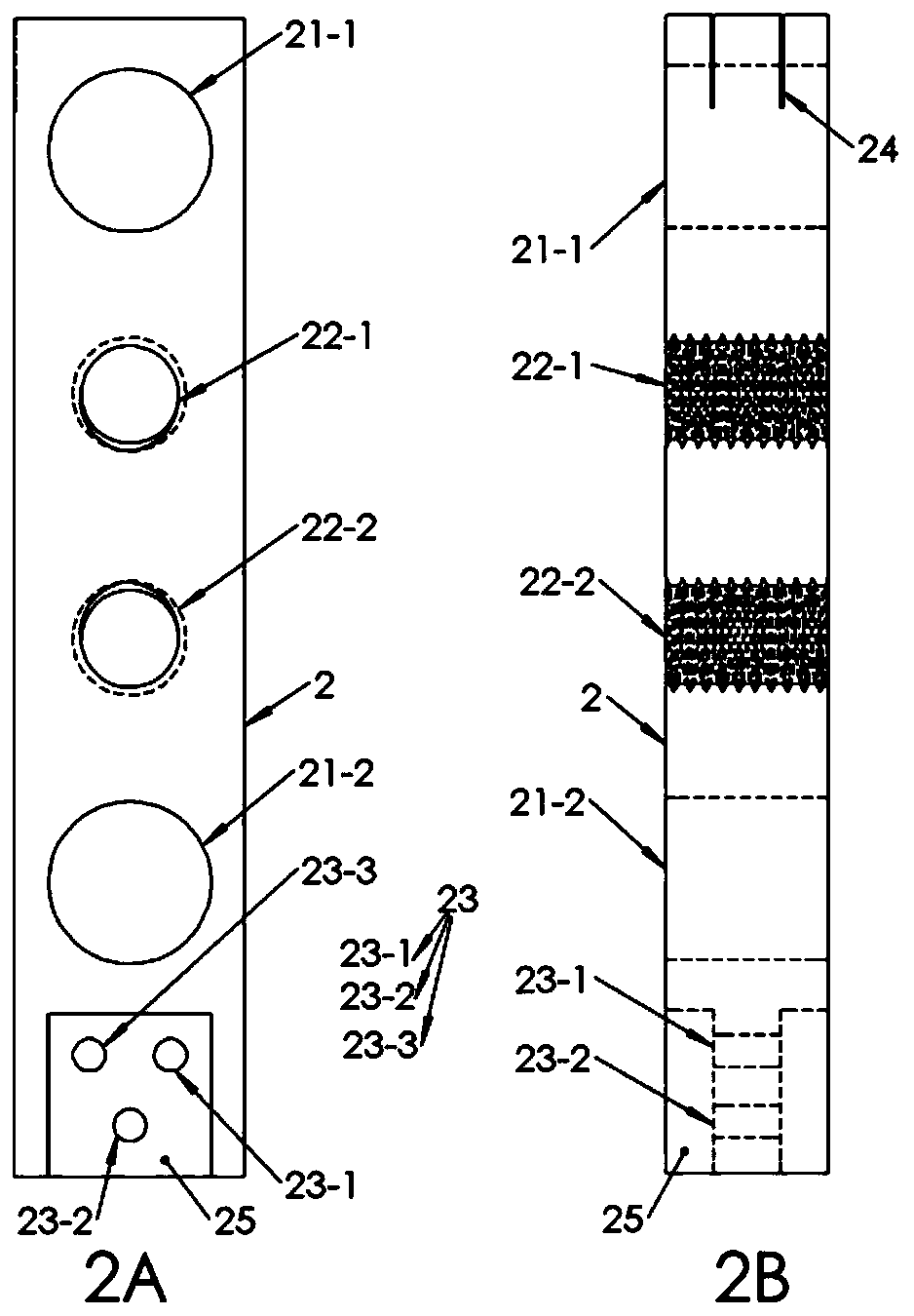

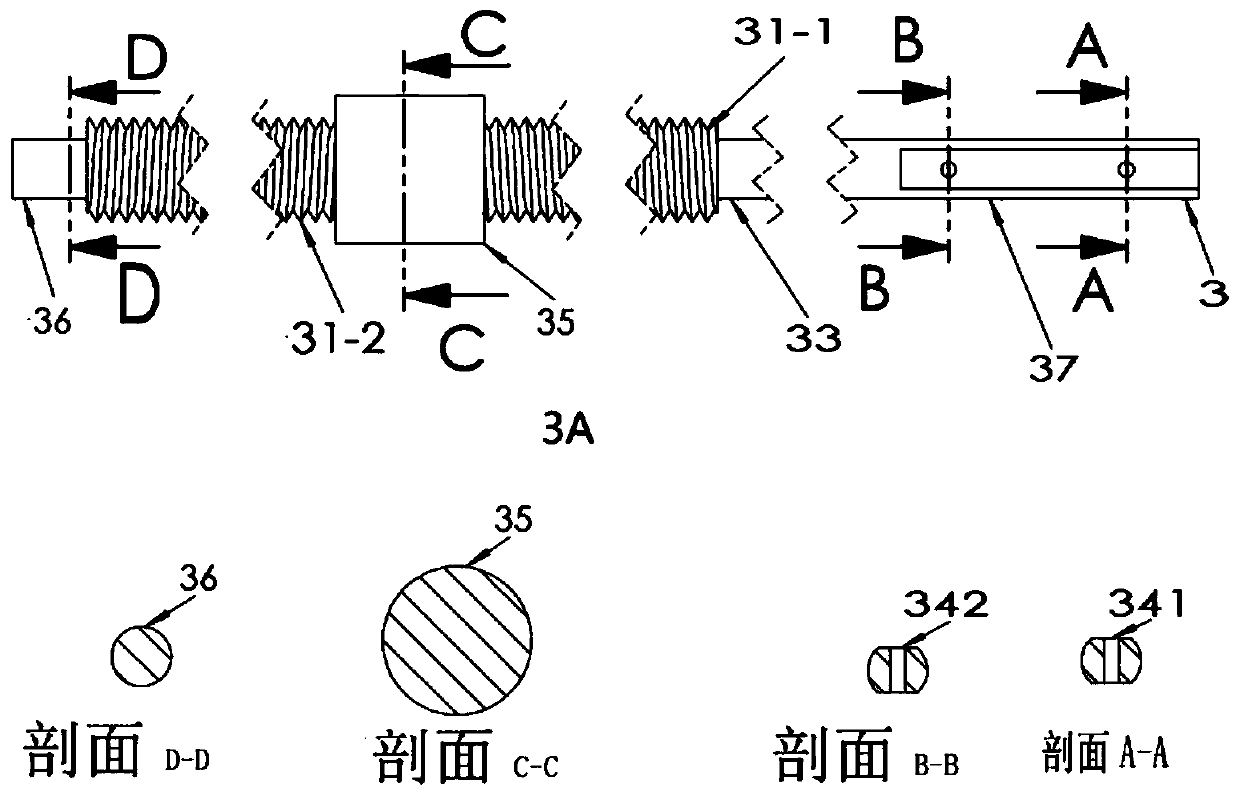

[0041] Embodiment 1, an adjustable hole opener is characterized in that: it includes a drill stand (1), a knife rest (2), a screw rod (3), a baffle plate (4), a guard plate (5), a positioning gear (6) ), buckle (7), blade (8), spring (9), button (10), scale plate (14), buckle plate (69);

[0042] The drilling frame (1) includes a support rod (1-1), a slide rail (1-2), a connecting column (1-3), a first screw hole (1-5-1), a second screw hole (1-5 -2); in the drill stand (1): the slide rail (1-2) consists of the first sliding column (1-2-1), the second sliding column (1-2-2), the third sliding column (1- 2-3), the fourth sliding column (1-2-4) constitutes;

[0043] In the drill stand (1): the first screw hole (1-5-1) and the second screw hole (1-5-2) are located on the support rod (1-1);

[0044] In the drill stand (1): the first sliding column (1-2-1), the second sliding column (1-2-2), the third sliding column (1-2-3), the fourth sliding column (1- 2-4), all four have a fi...

Embodiment 2

[0152] Embodiment 2, based on Embodiment 1, further: in the drill frame (1): the second end (1-4-1) of the first sliding post (1-2-1) has an eleventh installation hole ( 1-4-11); the eleventh mounting hole (1-4-11), the first sliding column (1-2-1), the axes of the two are perpendicular.

Embodiment 3

[0153] Embodiment 3, based on Embodiment 1, further: in the drill frame (1): the second end (1-4-2) of the second strut (1-2-2) has a twenty-first installation hole (1-4-21); the twenty-first mounting hole (1-4-21), the second sliding column (1-2-2), the two axes are vertical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com