Screen printing clamp

A fixture and screen printing technology, which is applied to screen printing machines, printing machines, printing machines, etc., can solve the problems of unable to effectively control the adsorption force, damage the glass screen, and low screen printing efficiency, and achieve multi-printing operations with one line and high fixing accuracy , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

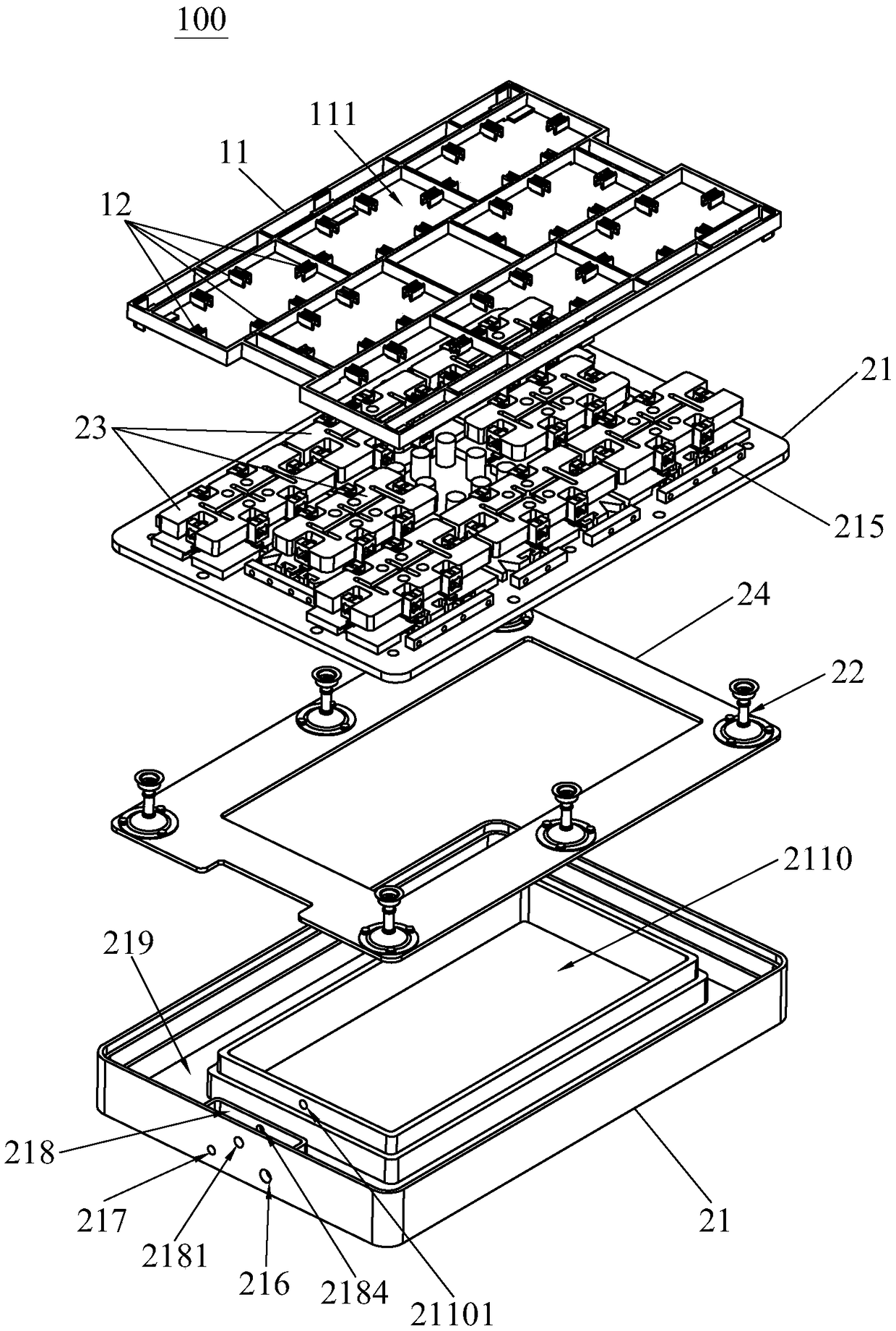

[0026] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like components.

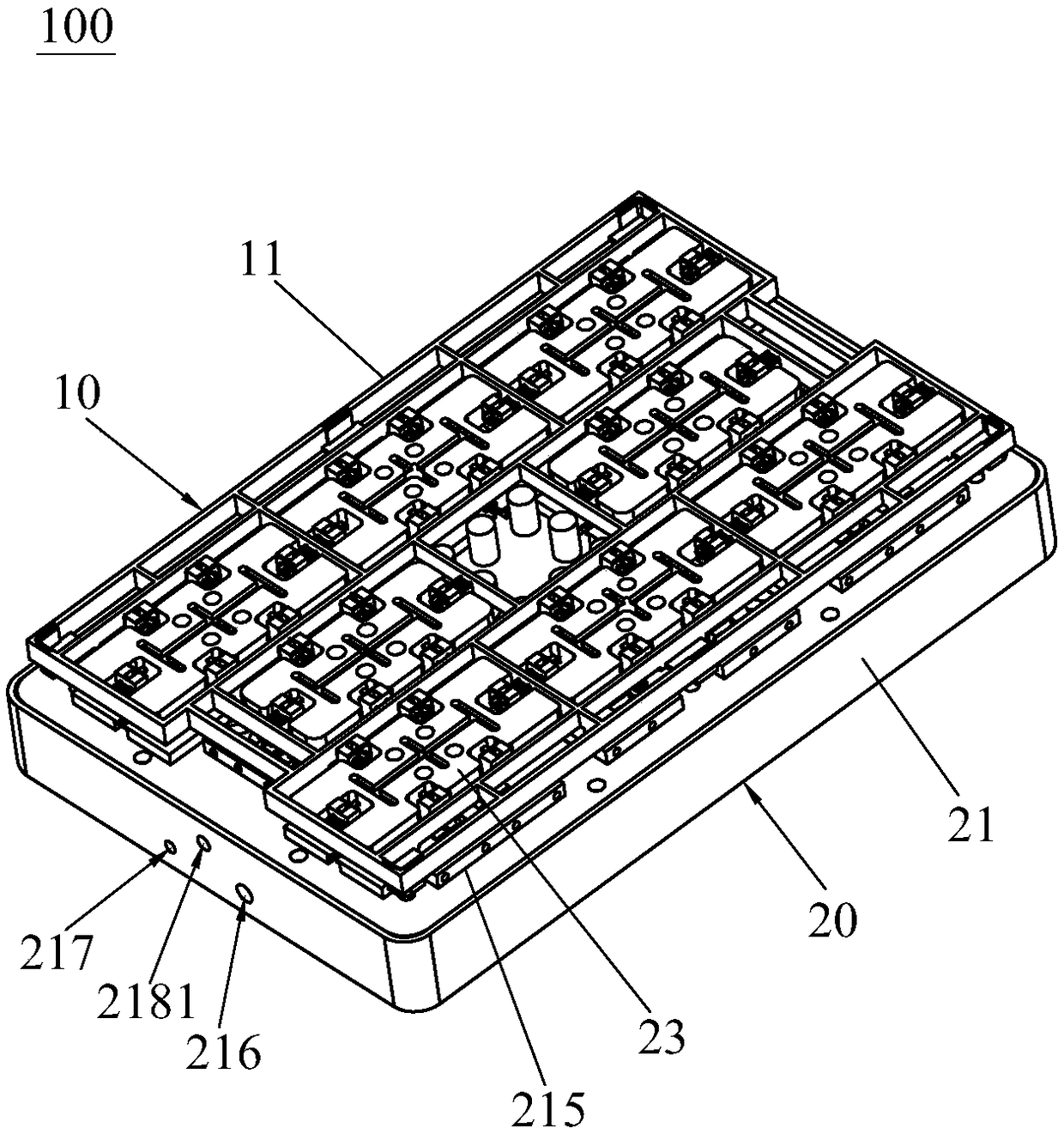

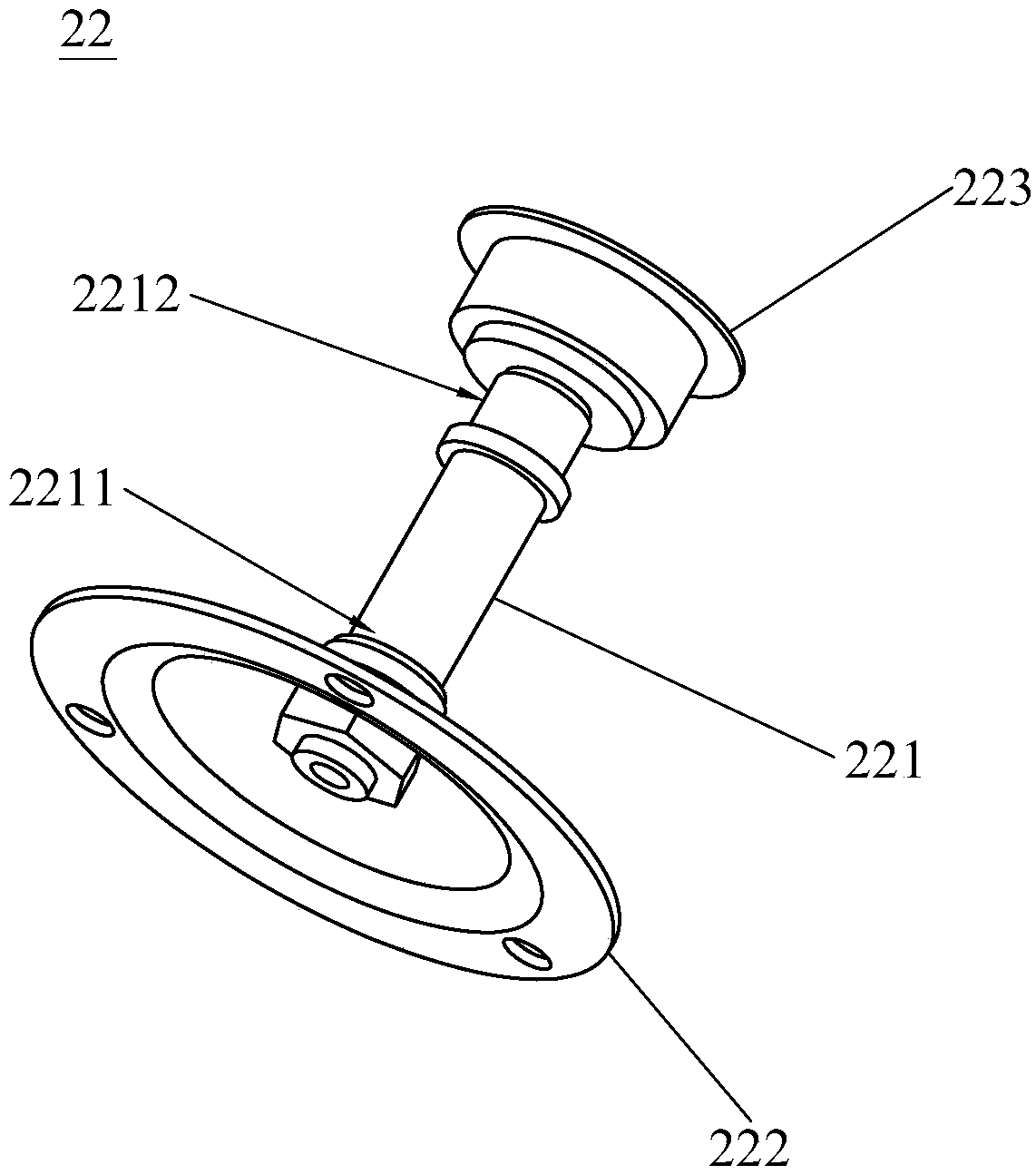

[0027] see Figure 1-Figure 10As shown, the screen printing fixture 100 of this embodiment includes a supporting mechanism 10 and a positioning mechanism 20 . Wherein, the support mechanism 10 includes a support frame 11 for carrying the glass screen (not shown in the figure) and a plurality of position limiting members 12. The support frame 11 is in a frame structure, and the frame structure forms a support frame for supporting the glass screen. In the support area 111, the limiter 12 is distributed along the edge of the support area 111. The limiter 12 is an optional locking glass screen. When the glass screen is carried in the support area 111, the limiter 12 supports and fixes the glass screen together. . Specifically, the supporting frame 11 of this embodiment is provided with eight supporting areas 111 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com