Insulating pad cutting and bonding integrated machine

A technology of insulating rubber pad and all-in-one machine, applied in the directions of cleaning methods and utensils, chemical instruments and methods, household appliances, etc., can solve the problems of low work efficiency, burrs, uneven cutting of insulating rubber pads, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

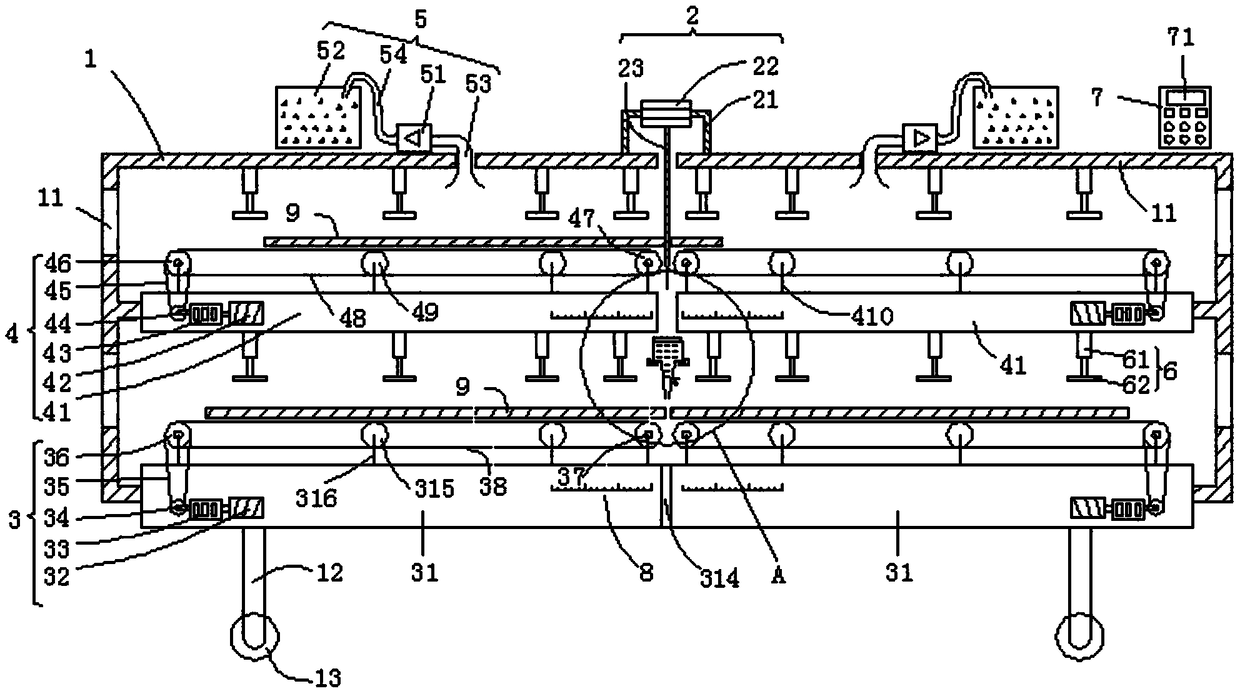

[0037] Furthermore, please also refer to Figure 1 to Figure 4 , as a specific embodiment of the insulating rubber pad cutting and bonding machine provided by the present invention, the bonding mechanism 3 is horizontally and symmetrically arranged in two groups, each including a bonding support frame 31 fixed at the lower part of the frame 1 , the second stepper motor 32 arranged in the bonding support frame 31, the second speed reducer 33 connected with the second step motor 32, the second small pulley connected with the second speed reducer 33 34. The second driving pulley 36 set at one end of the bonding support frame 31 and the second driving pulley 36 set at the other end of the bonding support frame 31 are connected to the second small pulley 34 through the second belt 35 in transmission The movable pulley 37 and the second conveyer belt 38 for transporting the insulating rubber pad installed between the second driving pulley 36 and the second driven pulley 37, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com