Method for measuring liquid-absorbing rate and liquid-absorbing volume of lithium ion battery pole piece

A lithium-ion battery, liquid absorption rate technology, applied in the direction of using material absorption and weighing, can solve the problems of complex structure and complicated operation, and achieve the effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

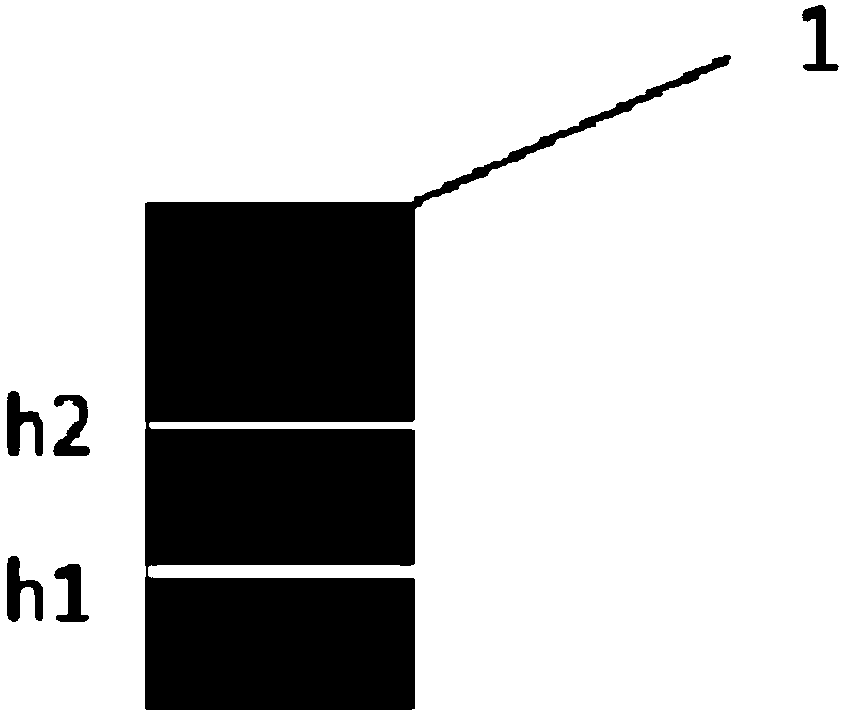

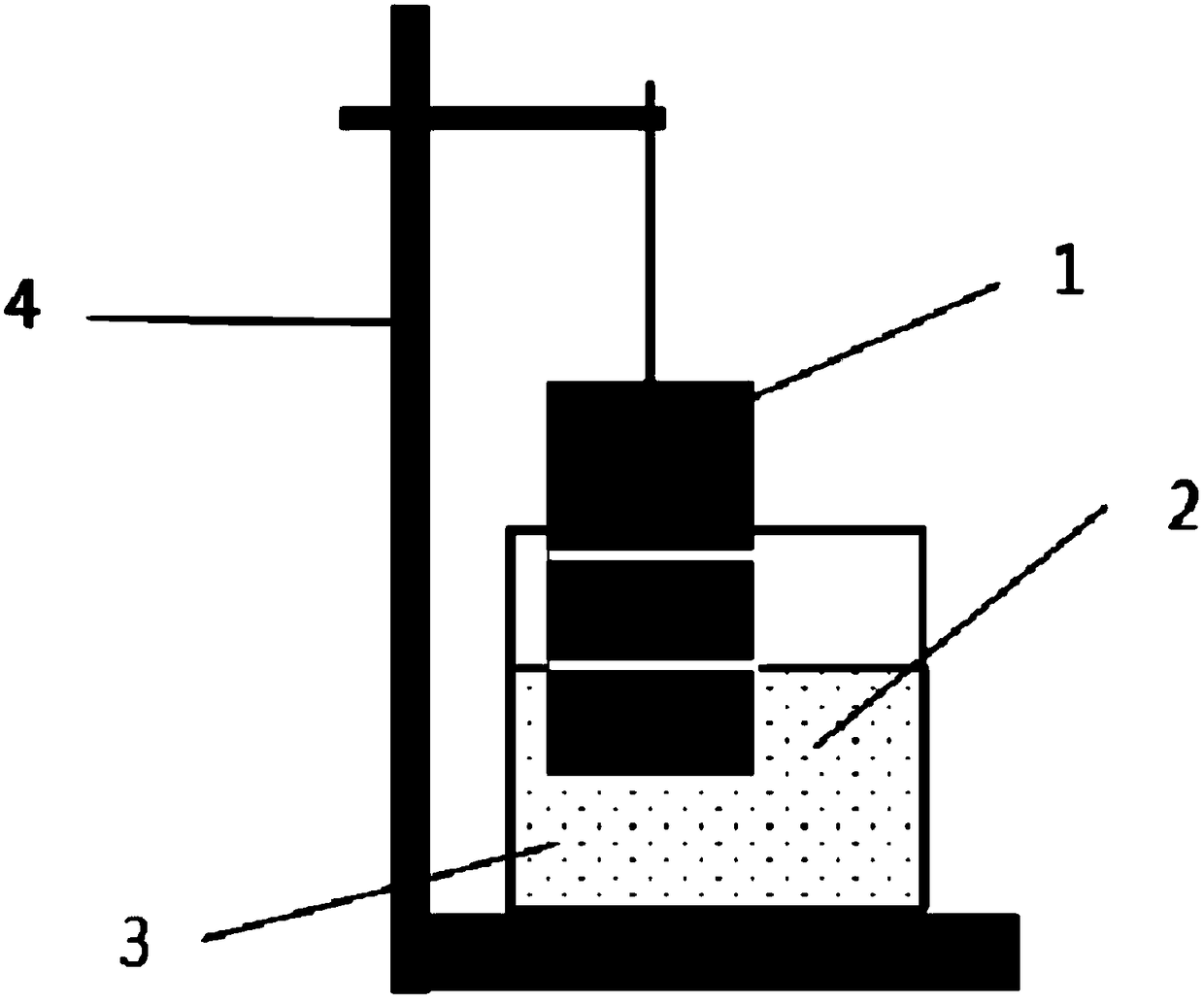

[0032] Place a ternary positive pole piece (length 102mm, width 84.5mm) horizontally on the table, draw a white line perpendicular to the height of the pole piece at a distance of 30mm and 60mm respectively. figure 1 As shown, drop a few drops of purple litmus test solution at 60mm of the white line (when the electrolyte spreads to 60mm, the white line will appear red), and weigh the pole piece weight M1 with an electronic balance. Put a certain amount of electrolyte in the beaker, and hang the pole piece vertically above the electrolyte through the iron stand; the end of the pole piece is flush with the electrolyte liquid surface, and the pole piece is immersed in the electrolyte 30mm (the scribe line is the same as the electrolyte (The liquid level is level), the pole piece starts to be immersed in the moment with a stopwatch. When the pole piece absorbs liquid until the white line appears red at the 60mm mark (the purple litmus test solution turns red when it meets the electro...

Embodiment 2

[0035] Place a ternary positive pole piece (length 102mm, width 84.5mm) horizontally on the desktop, and draw a white line perpendicular to the height of the pole piece at 30mm and 70mm from the tail end. figure 1 As shown, drop a few drops of purple litmus test solution on the white line 70mm (when the electrolyte spreads to 70mm, the white line will appear red), and weigh the pole piece weight M1 with an electronic balance. Weigh the pole piece weight M1 . Put a certain amount of electrolyte in the beaker, and hang the pole piece vertically above the electrolyte through the iron stand; the end of the pole piece is flush with the electrolyte liquid surface, and the pole piece is immersed in the electrolyte 30mm (the scribe line is the same as the electrolyte (The liquid level is level), the pole piece starts to be immersed in the moment with a stopwatch, when the pole piece absorbs liquid until the white line appears red at the 70mm mark (the purple litmus test solution turns r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com