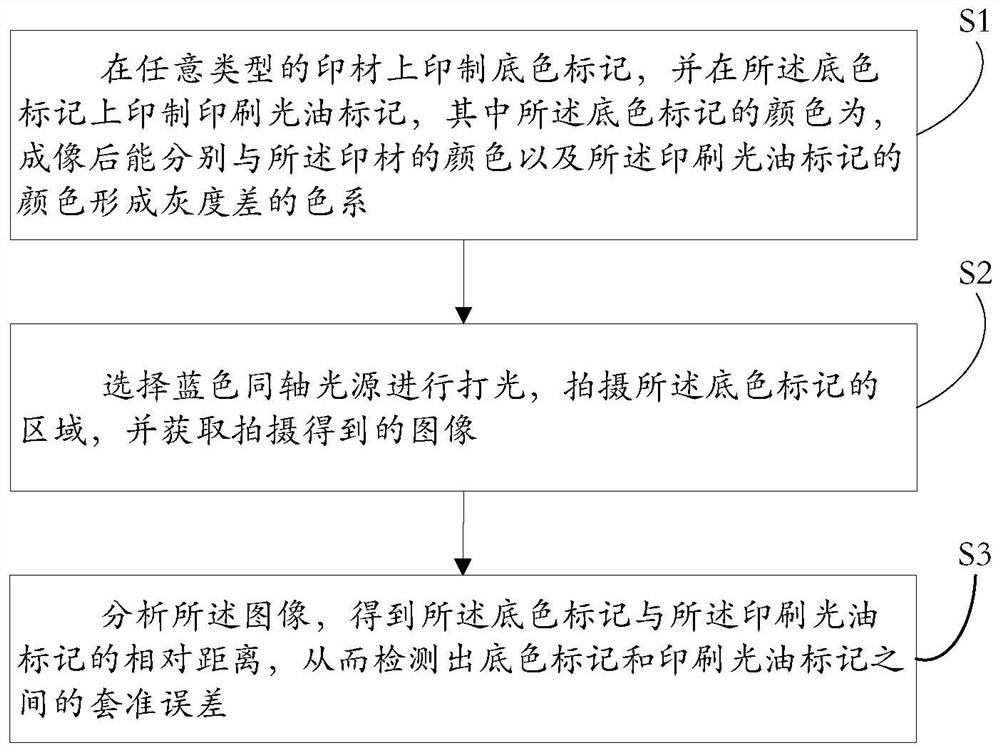

An image-based method for detecting registration errors of printing varnish

A technology of registration error and detection method, applied in the field of printing, can solve problems such as large detection error, and achieve the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The color of the base color mark 1 is yellow or red.

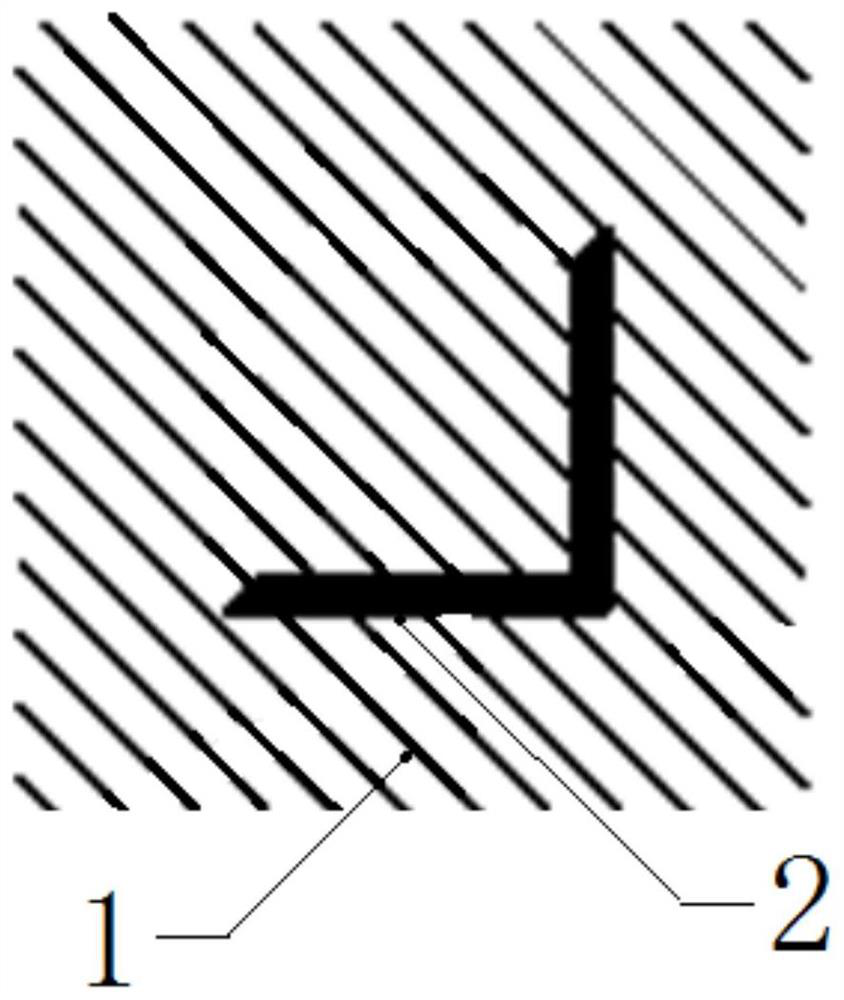

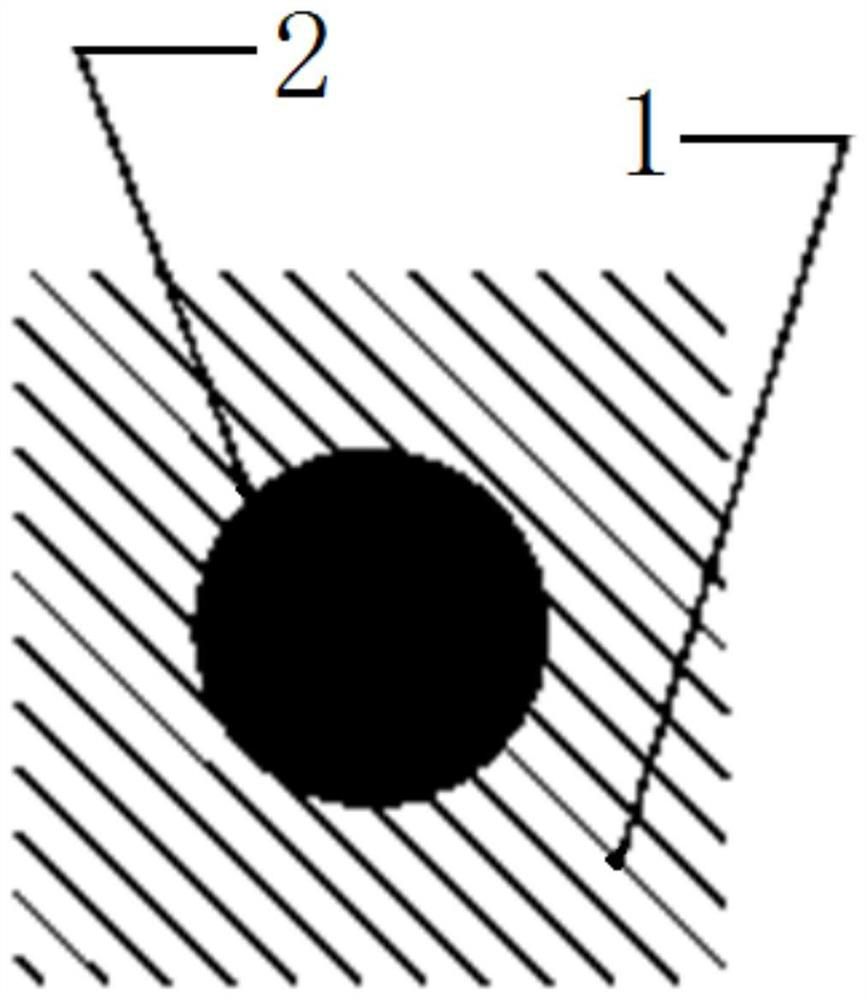

[0031] Embodiment 2: The printed varnish mark 2 is directly printed on the base color mark 1, and the shape of the printed varnish mark 2 is L-shaped or circular; as figure 2 As shown, the shape of the printed varnish mark 2 is L-shaped; as image 3 As shown, the shape of the printing varnish mark 2 is circular.

Embodiment 3

[0032] Embodiment 3: The base color mark 1 is provided with a hollow structure 3 , and the shape of the hollow structure 3 is the same as that of the printed varnish mark 2 . Specifically, the upper left corner of the base color mark 1 is hollowed out, and the printed varnish mark 2 is printed in the lower right corner. The shape of the hollow structure 3 and the printed varnish mark 2 can be L-shaped or circular; as Figure 4 As shown, the shape of the printed varnish mark 2 and the shape of the hollow structure 3 are both L-shaped; Figure 5 As shown, the shape of the printed varnish mark 2 and the shape of the hollow structure 3 are both circular.

Embodiment 4

[0033] Embodiment 4: The printing varnish in the printing varnish mark 2 is one of water-based varnish, UV varnish and glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com