Gas outburst elimination method combining downhole drilling, surface fracturing and downhole drainage

A combination of gas and gas technology, applied in the field of gas outburst elimination, can solve the problems that cannot meet the needs of rapid outburst elimination in coal mines, the construction scale and construction displacement are limited, and cannot meet the needs of coal mine production, so as to promote normal mining and stratum Uniform pressure and effective stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

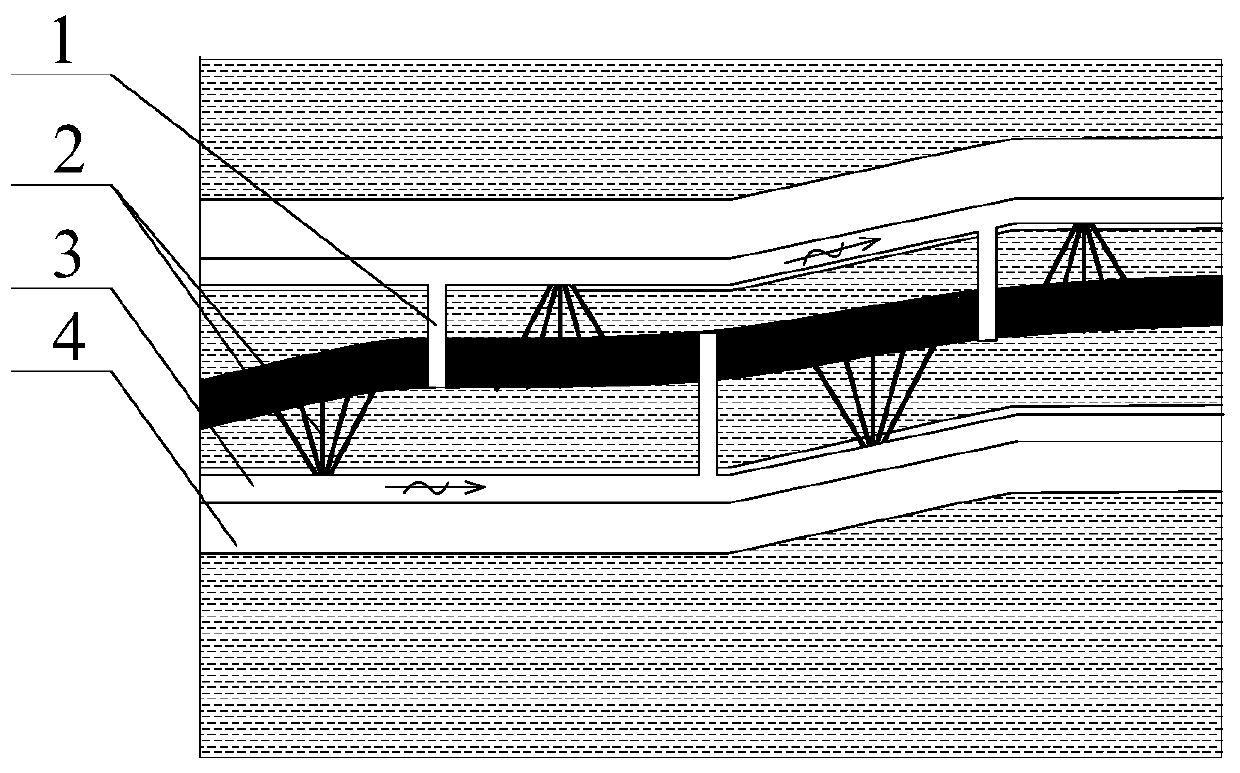

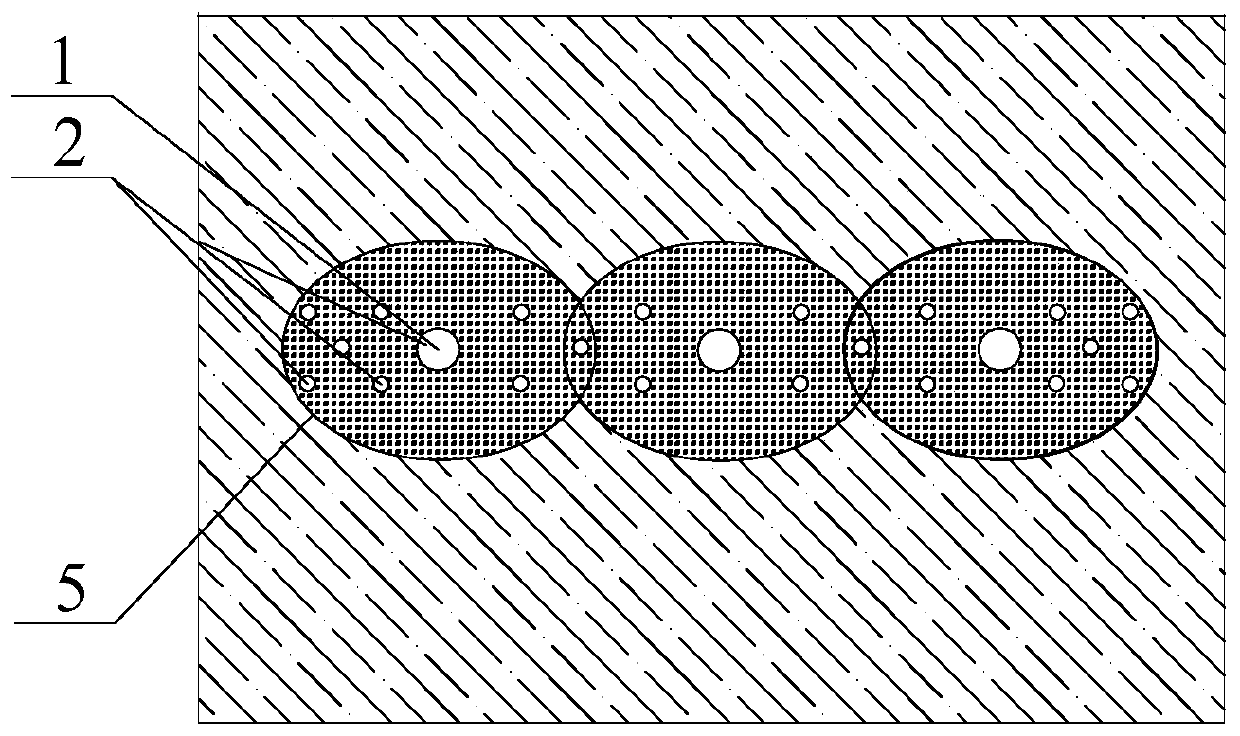

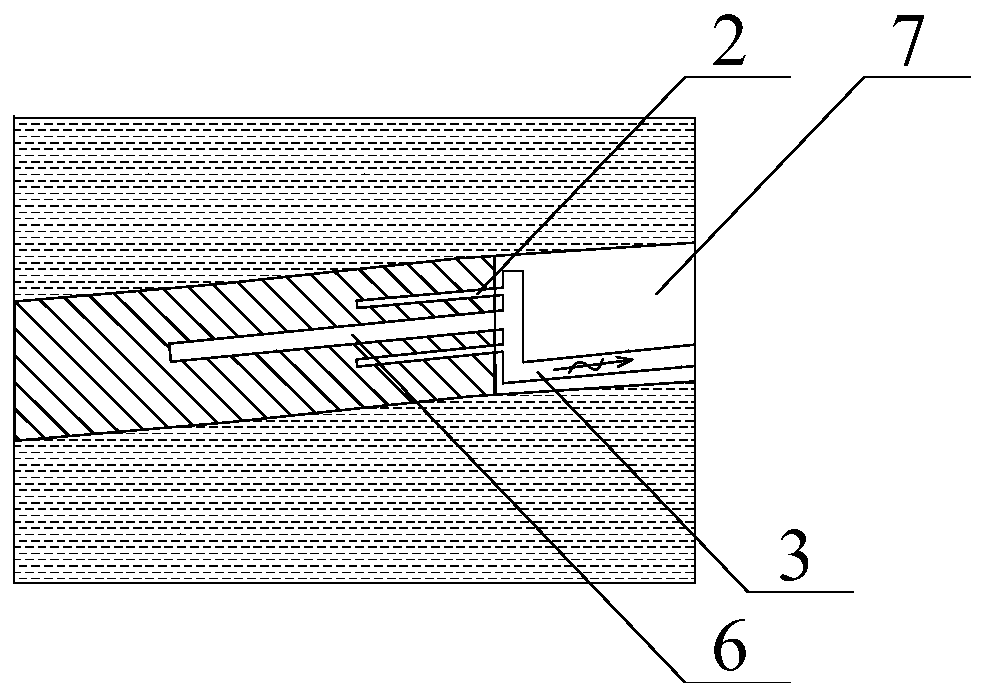

[0034] The embodiment of the present invention provides a gas outburst elimination method combining downhole drilling, surface fracturing and downhole drainage, such as Figure 1-4 As shown, it specifically includes the following steps:

[0035] S1. According to the geological data of the coal mine and the requirements of the mining progress of the coal mine, the gas content shall not be less than 8m 3 / t, and the coal reservoir with gas pressure not less than 0.74MPa is used as the area for gas outburst elimination, and the underground well position is arranged according to the production requirements of the coal mine and the actual situation of the underground roadway, and the well is drilled and cemented.

[0036] Specifically, the wellhead position and the bottom position of the underground drilling are both determined by the angle between the underground roadway and the direction of the maximum in-situ stress, and need to be reasonably arranged in consideration of the nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com