Integrative differential pressure type gas-liquid two-phase flow wellhead monitoring device

A monitoring device and differential pressure technology, which are applied in measurement, wellbore/well components, earth-moving drilling, etc., can solve the problems of inability to synchronously measure gas-liquid two-phase flow, and inability to realize flow conversion, etc., achieving simple structure and shortening The effect of length and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

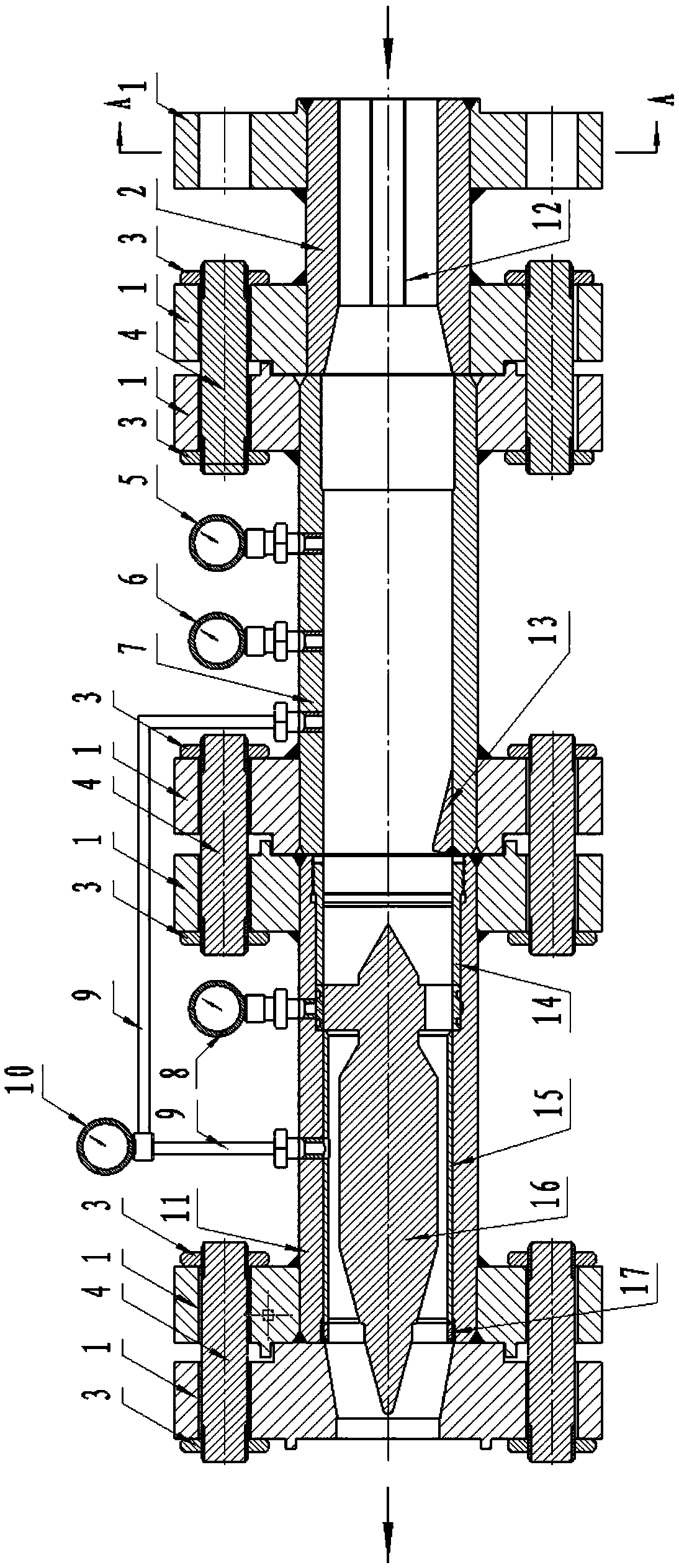

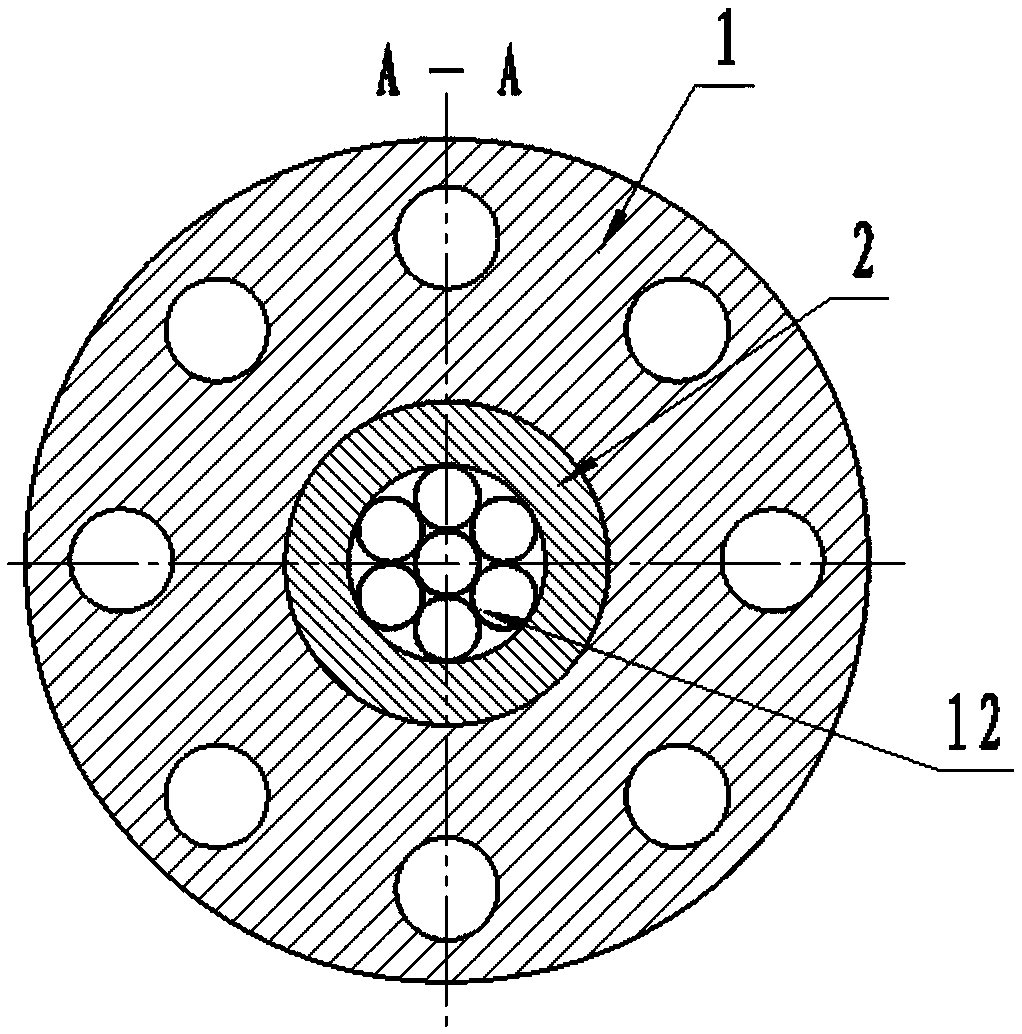

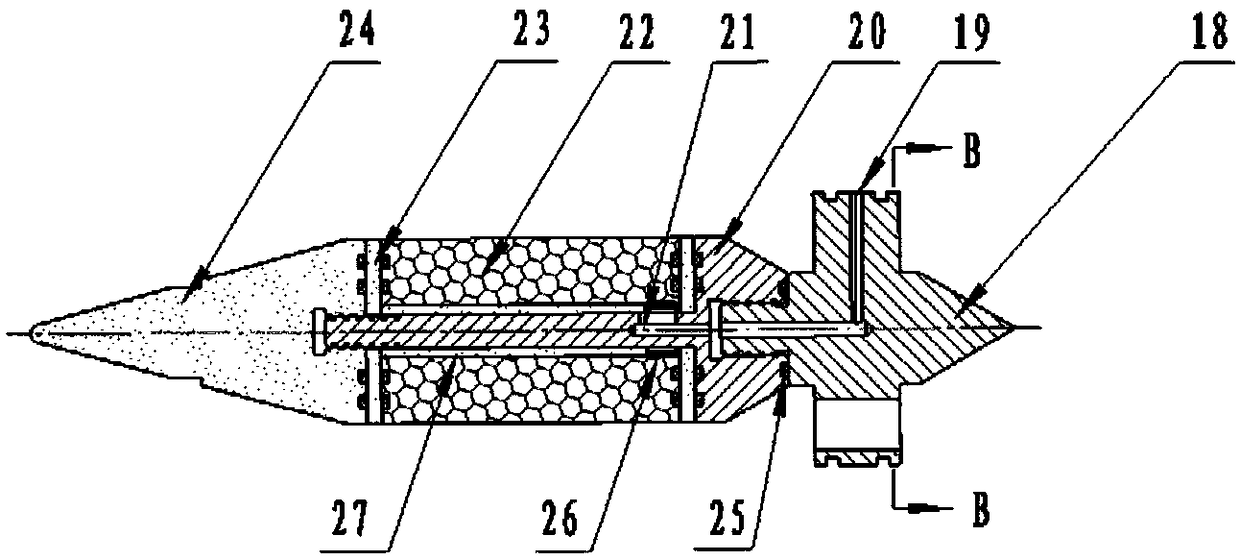

[0012] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: The present invention will be further described below in conjunction with the accompanying drawings. The present invention includes a flange 1, a shunt impact homogenizer 2, a nut 3, a bolt 4, a static pressure sensor 5, a temperature sensor 6, a static pressure device 7, a water content sensor 8, a pressure pipe 9, and a differential pressure flowmeter sensor 10. Anti-Venturi measurement cavity 11, homogenizer capillary 12, weir 13, upper backup cap 14, sleeve 15, water content radio frequency antenna assembly 16 and lower backup cap 17, wherein the flange 1 is connected to the shunt impact respectively The homogenizer 2, the static pressure device 7 and the reverse Venturi measuring chamber 11 are welded and connected, the shunt impact homogenizer 2 and the static pressure device 7 are fixedly connected by the nut 3 and the bolt 4 through the flange 1, the static pressure sensor 5 and the temperature sensor 6 It is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com