An integral low-rise building isolation mechanism

A shock-isolation and low-rise technology, which is applied in the direction of building components, buildings, building types, etc., can solve problems such as wall collapse, house eave damage, and the impact of house rainproof performance, so as to offset vibration, reduce impact, and have good protection effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

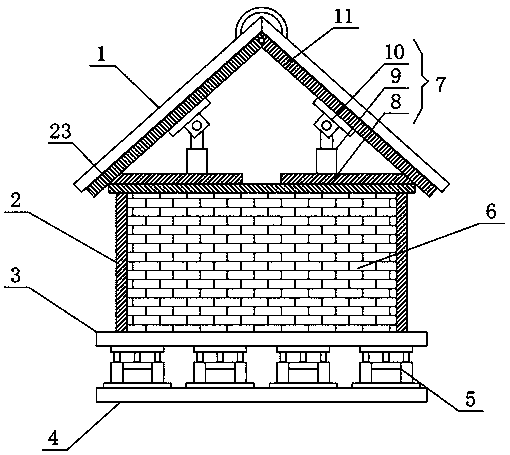

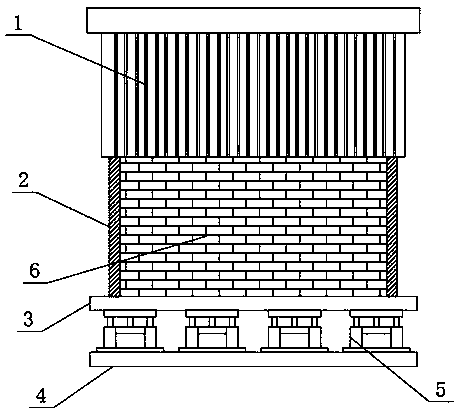

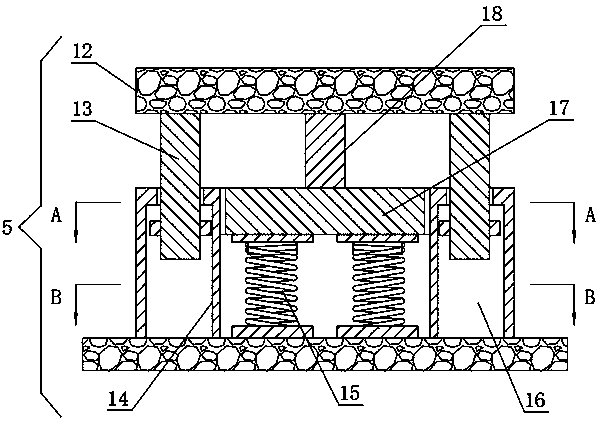

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , the present invention provides a technical solution: an overall low-rise building isolation mechanism, including a wall frame 2, a wall 6 built on the inner side of the wall frame 2, and a room base fixed to the bottom of the wall frame 2 by bolts 3 and the trough base 4 located at the bottom of the house base 3 and built in the gutter, the top of the wall frame 2 is fixed with a roof 23 by bolts, and the house base 3 and the gutter base 4 are fixedly connected by bolts There are multiple shock-isolation mechanisms 5; the top of the house roof 23 is welded with a roof frame 11 with an inverted "V" structure, and the inside of the roof frame 11 is provided with an auxiliary buffer mechanism 7; the top surface of the roof frame 11 is passed The rivet is fixed with the rain-shielding roof 1; the auxiliary buffer mechanism 7 includes a buffer column fixing block 10 fix...

Embodiment 2

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , the present invention provides a technical solution: an overall low-rise building isolation mechanism, including a wall frame 2, a wall 6 built on the inner side of the wall frame 2, and a house body fixed to the bottom of the wall frame 2 by welding The base 3 and the trough base 4 located at the bottom of the house base 3 and built in the trough, the top of the wall frame 2 is fixed with the roof plate 23 by welding, and the house base 3 and the trough base 4 are connected by bolts A plurality of shock-isolation mechanisms 5 are fixedly connected; the top of the house roof 23 is provided with a roof frame 11 in an inverted "V" structure by welding, and the inside of the roof frame 11 is provided with an auxiliary buffer mechanism 7; the top of the roof frame 11 The surface is fixed with a rain-shielding roof 1 by rivets; the auxiliary buffer mechanism 7 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com