Steel structure and concrete column connection structure and construction method thereof

A technology for concrete columns and steel structures, which is applied to building structures, building components, and earthquake resistance, can solve the problem that steel components cannot be fixed with concrete, and achieve the effects of improving structural strength, reducing friction, and preventing the shaking of the rotating rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

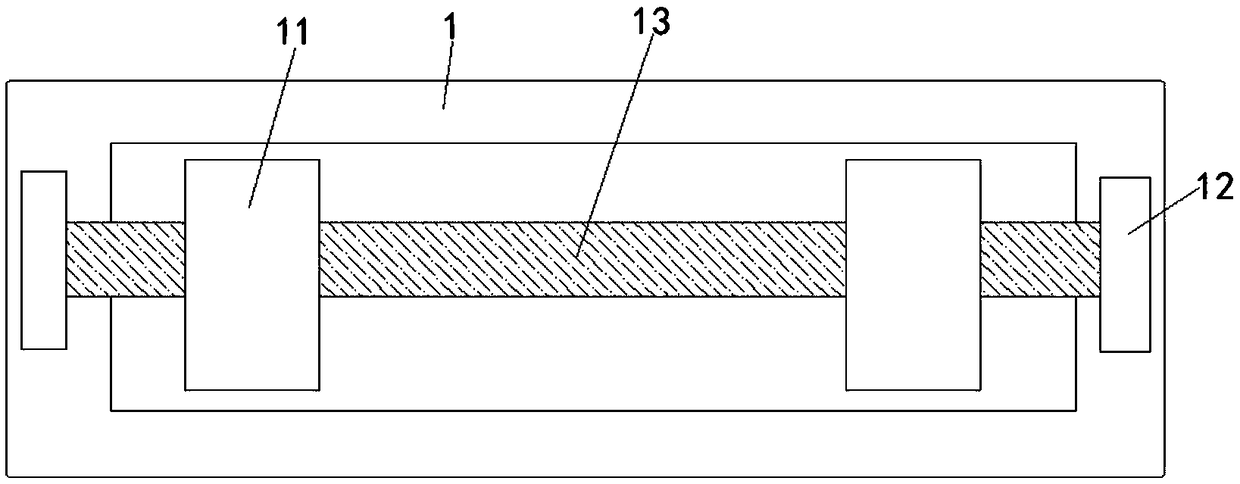

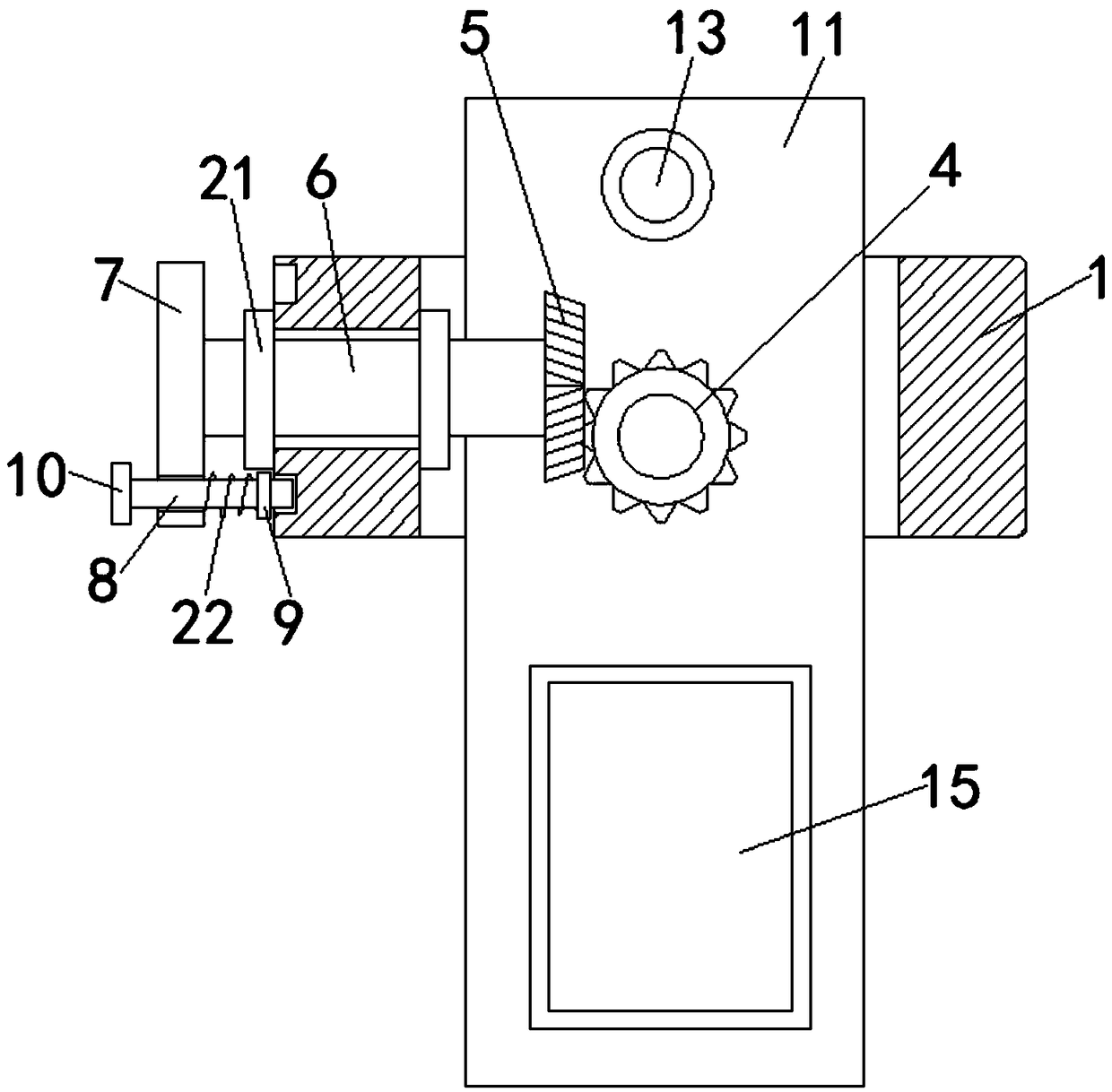

[0035] refer to Figure 1-3 , a connection structure between a steel structure and a concrete column, including a fixed plate 1, a port 2 is provided in the fixed plate 1 for setting a screw 3, and a screw 3 is connected to the port 2 for driving the extruded plate 11 to move , the screw rod 3 is fixedly sleeved with a first gear 4 for driving the screw rod 3 to rotate, and a second gear 5 meshing with the first gear 4 is provided in the port 2 for driving the second gear 5 to rotate, the second The inner wall of the gear 5 and the port 2 is connected through the rotating rod 6, which is used to drive the second gear 5 to rotate. The end of the rotating rod 6 away from the second gear 5 runs through the inner wall of the port 2 and is fixedly connected with a handle 7 for driving The rotating rod 6 rotates;

[0036] One end of the handle 7 is slidingly inserted with a clamping rod 8 for fixing the handle 7. The outer wall of the fixing plate 1 is surrounded by a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com